Mechanical Seal

Mechanical seals prevent liquid leakage by creating a hydrodynamic liquid film between two highly finished surfaces.

Mechanical seals prevent liquid leakage by creating a hydrodynamic liquid film between two highly finished surfaces.

Welcome! In this video we will guide you through the disassembly and reassembly of Viking Pump’s 893, 895, and 897 Series™ mag drive internal gear pumps.

This video applies to these pump models: GG893, HJ893, HL893, AS893, AK893, AL893, GG895, HJ895, HL895, AS895, AK895, AL895, GG897, HJ897, HL897, AS897, AK897, AL897

Viking Pump invented, patented and manufactured the very first sealless mag drive rotary positive displacement (PD) pumps in the world, and developed several series over time for different applications, including the first generation 825, 895 and 855 ™ internal gear pumps.

Of these first generation mag drive pumps, all had different footprints from their dynamically-sealed cousins with...

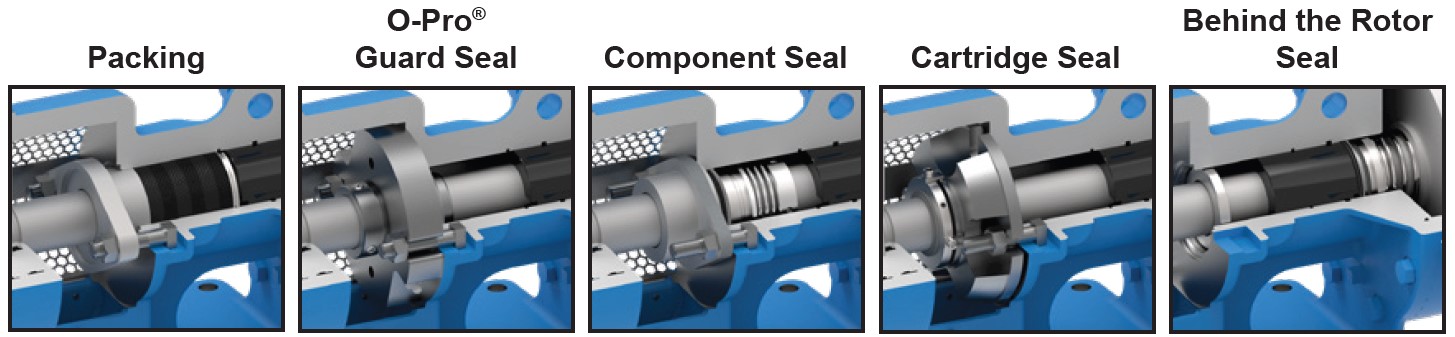

Packing is one of the most common and simplest seals for positive displacement pumps. Packing consists of braided or formed rings that are compressed inside the stuffing box of a pump. As the packing gland is tightened, the packing is compressed against the shaft and the inside of the stuffing box bore - creating a seal. When the pump is operating, process liquid cools and lubricates the packing. The pump must leak or "weep" slightly to ensure proper lubrication. Packing is one of the oldest forms of shaft sealing. Original packing was made of materials such as leather or rope.

The terms bitumen and asphalt are often used interchangeably, but they are two completely different materials, causing confusion inside and outside the industry. Throw in regional differences in meaning and language, and it’s time to set the record straight, along with tips on bitumen pump selection.

At Viking Pump, innovation is at the forefront of what we do. With the introduction of the U-Plus™ Bracket and ProPort™ Casing, we are redefining the capabilities of our internal gear pumps. These advancements are not just about new technology; they are about providing flexibility and efficiency in your pumping process. Let’s dive into what makes these innovations stand out.

Viking Pump’s new generation of pumps (sizes H-QS in steel and stainless steel) offer a wide array of benefits that the previous alloy pumps could not, particularly in the area of sealing flexibility. These new pumps increase the number of sealing options possible in one pump, while at the same time reducing cost and lead times.

Viking Pump’s new generation of internal gear pumps offer a wide array of benefits that the previous alloy pumps could not, particularly in the area of porting flexibility. These new pumps reduced the number of casing configurations, which helps reduce manufacturing complexity, cost and lead times, while at the same time increasing the number of porting options and providing greater porting flexibility.

As a masterclass in engineering design and manufacturing flexibility, Viking Pump has re-designed its heavy-duty alloy pumps, both steel and stainless steel, in the most ingenious ways. These new models reduce price and lead time by significantly reducing the number of casings and brackets for manufacturing simplification, while simultaneously providing more options for porting and shaft sealing, all while adding many great new standard features.

Unlike food processors who primarily use centrifugal pumps, chocolate and confectionery processors have two main preferences for handling viscous liquors, chocolates, sugars and other confectionery liquids: Rotary Lobe / Circumferential Piston (CP) pumps and Internal Gear Pumps. These Positive Displacement-type pumps are chosen due to various reasons. But which is best?