The terms bitumen and asphalt are often used interchangeably, but they are two completely different materials, causing confusion inside and outside the industry. Throw in regional differences in meaning and language, and it’s time to set the record straight, along with tips on bitumen pump selection.

What is Bitumen

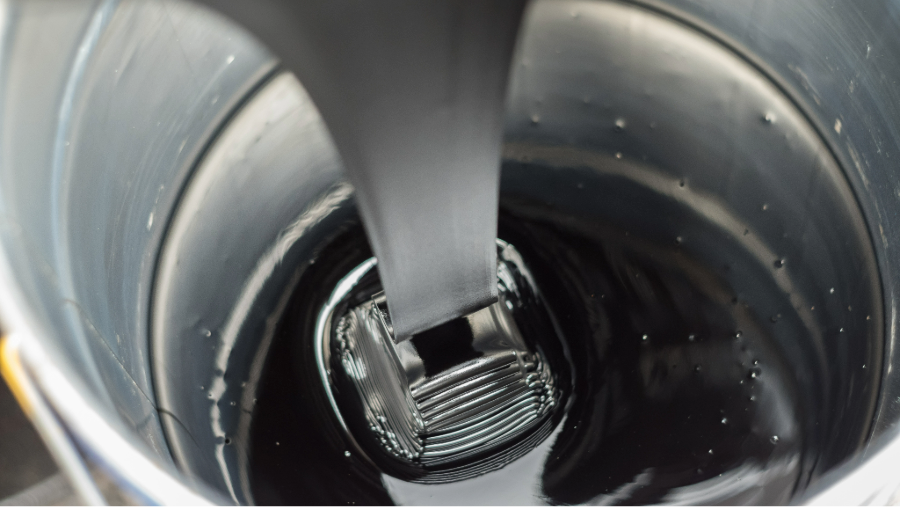

Bitumen is a form of petroleum that is sticky, black, and highly viscous liquid usually produced as a residual of oil refining but is also found in natural deposits in several areas of the world. Bitumen is man's earliest organic engineering material, and its adhesive properties make it the ideal application as an adhesive and waterproofing material dates to the dawn of civilization.

There are several types of bitumen and uses. Bitumen thrives in a wide range of markets including road building, roofing, and waterproofing in the construction industry, as well as use in rubber and adhesive compounds. In some parts of the world it is known as asphalt cement or asphalt binder, or bitumen cement or bitumen binder. When heated to a liquid state bitumen may be pumped with a positive displacement pump, usually an internal gear pump.

What is Asphalt

Asphalt is a blend of bitumen and dry aggregate (rock) material that is made in an asphalt blending plant to be used for paving roads. It’s made by combining hot liquid bitumen and aggregate in a rotating drum. Once mixed, the asphalt mixture cannot be reliably pumped due to excessive wear created by the aggregate, so it is conveyed into dump trucks and then hauled to the job site where it is laid on the roadbed, compacted into a smooth surface, and allowed to cool, enabling traffic to resume much more quickly than its main competitor, concrete.

Asphalt is infinitely recyclable, with old asphalt roads removed and milled into small pieces so they can be blended into fresh bitumen and aggregate to make new asphalt. Bitumen must be heated to a sufficiently high temperature to enable being mixed with the aggregate and then trucked to the jobsite and placed before it cools and hardens. It may be processed as Hot Mix, Warm Mix or Cold Mix.

Hot Mix Asphalt

Hot Mix asphalt is produced at temperatures between 150 and 180°C.

Warm Mix Asphalt

Warm Mix asphalt is produced at temperatures around 20 to 40°C lower than an equivalent Hot Mix.

Cold Mix Asphalt

Cold mix is a blend of emulsified bitumen and aggregate at ambient temperature.

BITUMEN GRADING

Bitumen cement is a refined bitumen that meets quality and consistency standards for direct use in the construction of bitumen pavement mixtures. In the EU bitumen is graded according to penetration tests pursuant to EN 12591:2009. Penetration grading’s basic assumption is that the less viscous the bitumen, the deeper a needle will penetrate under 100 gram load at 25⁰C for 5 seconds.

Penetration grades are listed as a range of penetration units (one penetration unit = 0.1 mm) such as 70/100. Different penetration grades are listed below. The hardest bitumen (lowest penetration) is 35/50 and is used in warmer regions, softest is 100/150, used for cold climates.

|

|

Units |

Bitumen 35/50 |

Bitumen 40/60 |

Bitumen 50/70 |

Bitumen 70/100 |

Bitumen 100/150 |

Test Methods |

|

Penetration @25°C, 100gm, 5sec |

0.1MM |

35-50 |

40-60 |

50-70 |

70-100 |

100-150 |

EN 1426 |

|

Softening Point, Ring & Ball |

°C |

50-58 |

48-56 |

46-54 |

43-51 |

39-47 |

EN 1427 |

|

Flash Point Cleveland open cup, Min |

°C |

240 |

230 |

230 |

230 |

230 |

EN ISO 2592 |

|

Kinematic Viscosity @135°C, Min |

mm2/S |

370 |

325 |

295 |

230 |

175 |

EN 12595 |

POLYMER MODIFIED BITUMEN

Bitumen cement may be blended with virgin solid or liquid polymers or with ground rubber from discarded tyres with steel belting removed. To completely blend these polymers requires higher temperatures than standard bitumens, sometimes as high as 260⁰C.

Polymer modified bitumens used in road construction provide greater resistance to fatigue, reduced risk of cracking, improved durable surfaces, better weather resistance, greater adhesion to aggregates and greater resistance to deformation and rutting. They must conform to EN 14023:2010.

EMULSIONS

Emulsified bitumens are mixtures of bitumen or polymer-modified bitumen with a surfactant and water. They are used in preparing base courses for asphalt surfaces, in cold laid mixes, mix-in-place, and surface treatments. It tends to be sensitive to weather conditions; Most emulsions must not be subjected to climate conditions below 0°C because freezing of the aqueous solution will coagulate the bitumen particles. Temperatures above 100°C must also be avoided or the water can vaporize and create dangerous pressures inside piping. Emulsions have largely replaced cutback asphalts, which use solvents that evaporate, leaving the hardened bitumen topcoat on asphalt roads.

Emulsified bitumen is produced at both the refineries where the bitumen is produced, and at facilities solely built to produce emulsified bitumen. Positive displacement pumps are used for metering the bitumen and the aqueous solutions to the mixer or colloid mill. Emulsions must conform to EN 13808:2013.

BITUMEN GEAR PUMP SELECTION

For bitumen pumping we recommend that you take the following into consideration when selecting an internal gear positive displacement pump for a variety of applications related to bitumen:

- Steel fitted construction and extra clearances may be required, depending on the range of possible viscosities.

- Bronze bushings can be utilized for conditions up to 232°C. Carbon graphite is required for temperatures above 232°C. High temperature graphite may be required depending on the pump size.

- Acceptable shaft seals include:

- Packing

- Viking’s patented O-Pro® Cartridge seal with high temperature O-rings

- Cartridge lip seal with quench

- Single metal bellows mechanical seal with hard faces and quench

- Double metal bellows mechanical seal with hard faces (inboard) and a pressurized barrier fluid

- Temperature resistant pumps should be either electrically heated or jacketed to accept a heat transfer fluid such as steam or heat transfer oil. Ensure that bitumen in the pump and lines is melted before startup. Avoid electric heat on emulsions, since momentary temperatures can exceed 100⁰C even if the controller is set for less than that.

For help with selecting the right pump for your bitumen needs, contact a Viking Pump representative at vikingpump.com/contact.

About the Author

John Hall has held marketing, sales, and technical management roles for several pump manufacturers, including 23 years at Viking Pump before retiring in 2023. He holds a B.S. in Technical Communications and an MBA in Marketing Management from the University of Minnesota.