Unlike food processors who primarily use centrifugal pumps, chocolate and confectionery processors have two main preferences for handling viscous liquors, chocolates, sugars and other confectionery liquids: Rotary Lobe / Circumferential Piston (CP) pumps and Internal Gear Pumps. These Positive Displacement-type pumps are chosen due to their:

- Slow speed and low shear which prevents separation of cocoa butter from chocolate solids

- Flow rate which is proportional to speed, enabling easy flow control with Variable Frequency Drives (VFDs)

- Ability to handle a broad range of viscosities, from cocoa butters <33 cSt to dark or milk chocolates >25,000 cSt, which enables a facility to standardize on just two or three pump sizes throughout the process, simplifying maintenance and reducing spares inventory.

But which is best? It depends on the application as well as the Process Engineers’ and Maintenance Managers’ experiences and preferences, but both have their place, frequently in different locations in the same processing facility.

Chocolate Pumping Rule Of Thumb: “Pathogen-Potential Liquids: Lobe/CP Pumps. Everything Else: Gear Pumps”

While not absolute, this rule of thumb represents both common practice amongst many larger processors, and application of best practices for maximizing reliability and uptime, minimizing maintenance costs and ensuring the appropriate level of hygiene.

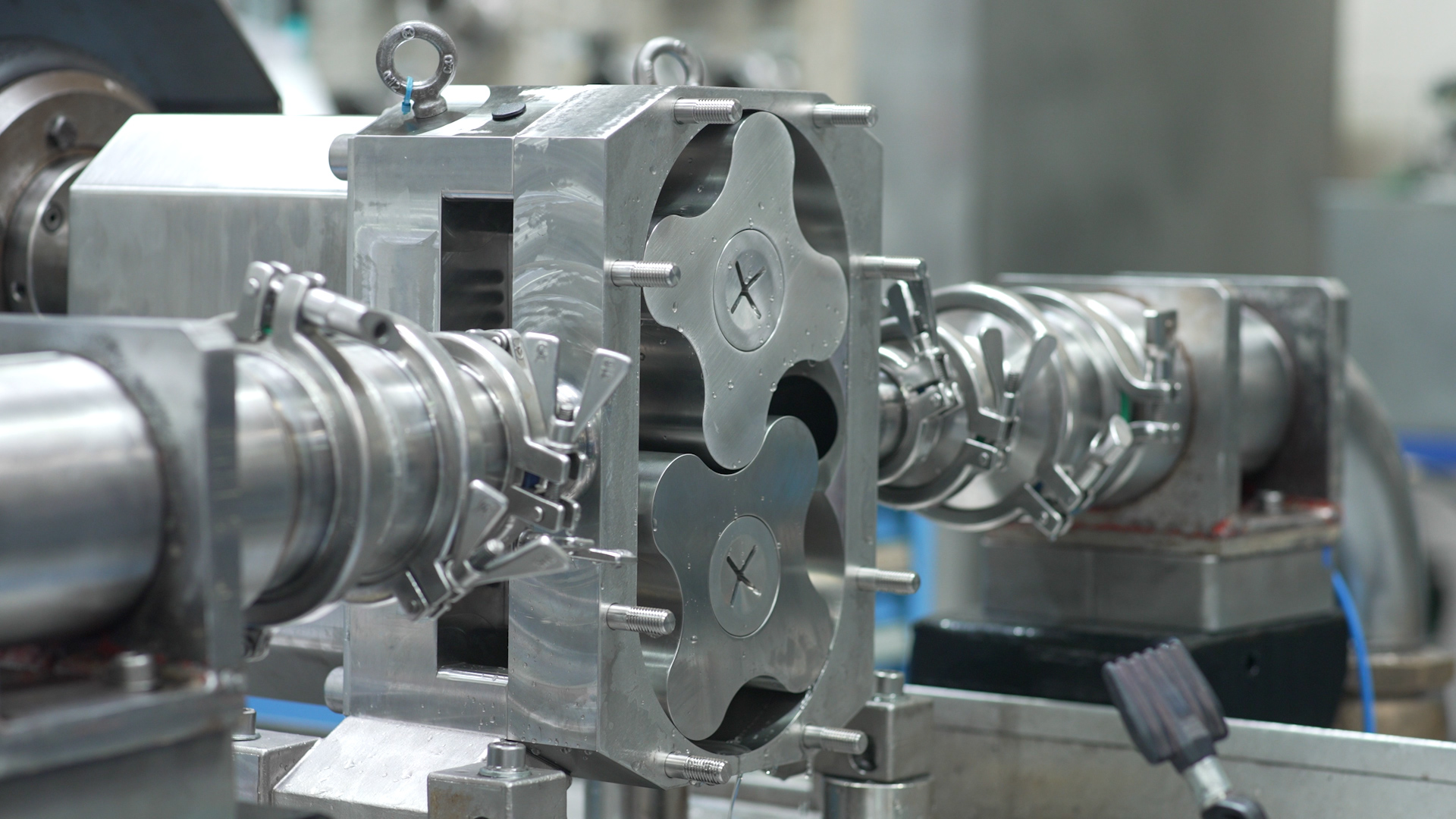

Hygienic Lobe and Circumferential Piston Pumps

Hygienic Lobe and Circumferential Piston Pumps are used where cleanability and corrosion resistance are required. These stainless steel pumps are used where lines are periodically Cleaned-In-Place, both to resist corrosion from the cleaning chemicals and to enable complete cleaning in the shortest time possible. An internal oil-lubricated gearbox contains two timing gears, one on the driver shaft and one on the driven shaft, which synchronize the position of the rotors so that they never contact each other.

They are used on liquids which have the potential to grow pathogens, including dairy products (milk or cream) and liquid sugars and syrups, as well as milk chocolate and chocolate syrup products which contain those ingredients. Stainless steel pumps are also preferred for white chocolate because it is possible for iron pumps and piping to oxidize sufficiently to colour the chocolate, although both Lobe/CP and Gear pumps are available in stainless steel. Lobe/CP pumps are more susceptible to abrasion than gear pumps, so are mostly used in downstream chocolate applications like discharge from the refiner or conch to storage tanks or depositors, panners or enrobers, because at that point the abrasiveness of the chocolate has been minimized and will not cause excessive wear on the stainless steel rotors (lobes or circumferential pistons).

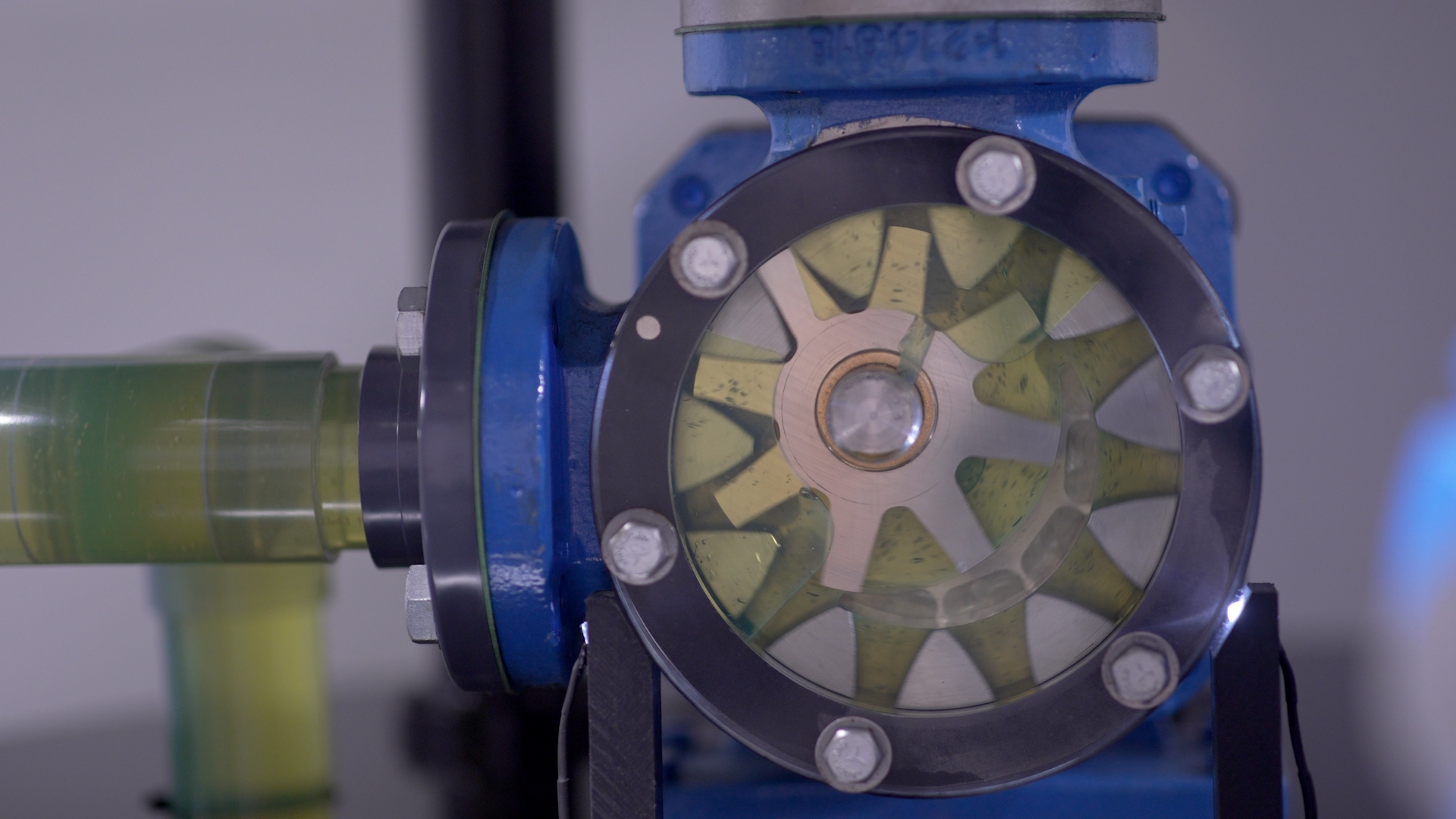

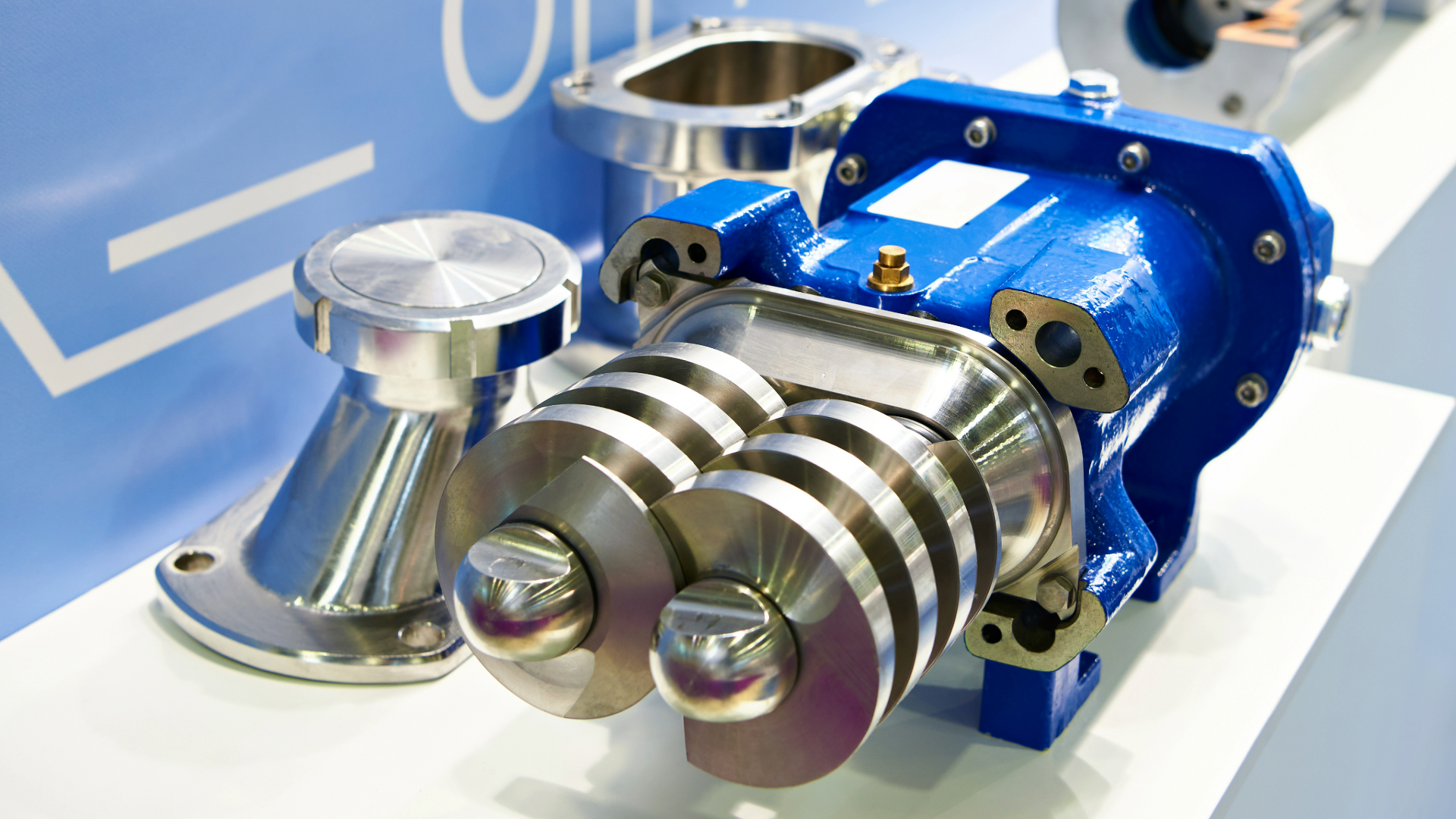

Internal Gear Pumps

Internal gear pumps constructed of cast iron are extremely wear-resistant, dependable, long-lived, and lower cost. As the name implies, an external driver gear (rotor) turns an internal driven gear (idler), which creates large cavities that draw liquid in and then force it out. Because chocolates are essentially edible oils with solids, similar to nut butters, they lubricate the sliding gear faces to prevent contact and wear, and they do not support growth of pathogens. Chocolates are difficult to seal, so a key benefit to this technology is that there is only one shaft seal to maintain compared to two on Lobe/CP pumps.

A second reason they are used in upstream applications like cocoa mass and chocolate liquor is that gear pumps with high strength steel or ductile iron rotors and hardened cast iron bushings are capable of handling these very abrasive products with minimal wear, while stainless steel Lobe/CP pumps wear more quickly, requiring more frequent maintenance. A further benefit is that any iron or steel that is worn from a gear pump will be removed by magnetic separators without wasting any product, while detecting stainless steel shards with a metal detector requires the final product to be discarded.

Gear pumps are commonly used for dark chocolate and lecithin because of their lower initial and life cycle costs. Cocoa butter, cocoa butter equivalent (CBE) and other edible oils are handled by gear pumps because the single shaft seal is less likely to leak than the twin seals on lobe pumps, and those liquids are a slip and fall hazard if they reach the floor. Gear pumps are commonly found handling all chocolates on OEM process equipment like melters, temperers, enrobers and depositors because they often must be mounted in relatively inaccessible locations on the equipment. Since they use H1 food grade grease for lubrication rather than oil like Lobe pumps, preventive maintenance is easier and mounting may be in horizontal or vertical configurations.

Internal Gear pumps should, at a minimum, be constructed of approved food contact materials (Viking chocolate pumps conform to EC1935 for food contact), but they are not hygienic, as in being completely CIP-able. This is not required for any of the liquids described above, because their systems are never cleaned with water or cleaning chemicals, which would only contaminate the chocolate. You generally find iron gear pumps where the piping, valves and appurtenances are also iron. Where the piping transitions to stainless steel is often where you begin to find Lobe or CP pumps (or stainless steel internal gear pumps).

What about External Gear and Twin Screw Pumps?

While both have been used to pump chocolate, they may not be the best choice for several reasons. A key issue with External Gear pumps is that while they have only one shaft seal, they have four sleeve bearings (bushings) lubricated by the pumped liquid, compared to two sleeve bearings with internal gear pumps, and only one with Viking’s 1124A-CHC chocolate pumps.

Abrasive wear in these bearings leads to failure, and twice as many bearings leads to faster failure and more maintenance. Twin Screw pumps are similar to lobe pumps in that they are offered in hygienic design and have two shaft seals. Their claim to fame is the ability to operate at slow speeds on viscous liquids and then at high speeds to act as a Clean-In-Place (CIP) pump on dairy applications, eliminating the need for a separate centrifugal CIP pump. The main issue is that the screw pump must be run using just a VFD without a gear reducer to enable both high speeds for CIP-ing and very low speeds for processing. This requires vastly oversizing the motor and VFD kW ratings to run at very low frequencies without overheating, resulting in low efficiencies and higher life cycle costs than Lobe pumps, which always use a gear reducer (and may use an appropriately sized VFD). Twin screw may be appropriate for lower-viscosity, pathogen-potential liquids like milk, where it can be run at high speeds and drive equipment need not be oversized.

To Sum It Up...

Some facilities will choose to use nearly all gear pumps and some will choose to use nearly all Lobe or CP pumps for commonality of parts, and either is acceptable, but the rule of thumb “Pathogen-Potential Liquids: Lobe/CP Pumps. Everything Else: Gear Pumps” provides a blueprint for cost-effective and reliable processing.

To better understand how each of these pumps works, see these short videos:

About the Author

John Hall has held marketing, sales, and technical management roles for several pump manufacturers, including 23 years at Viking Pump before retiring in 2023. He holds a B.S. in Technical Communications and an MBA in Marketing Management from the University of Minnesota.