Viking's energy pumps are used in almost every process where oil or oil derivatives are found. With the advancements in unconventional oil exploration and production, Viking Pump has created a series of oil and gas tailored products for the upstream and midstream oil fields, specifically for LACT (Lease Automatic Custody Transfer) pipeline injection service as well as gas dehydration applications.

Rugged and Reliable Oil & Gas Pumps

Understanding your specific applications and needs is priority number one, and any of our pump experts have the knowledge and experience to make pump recommendations and selections. We are also driven to understand the complete process of where our pumps will be placed. Viking Pump has been a premier pump of choice in all midstream applications on or around the pipeline injection unit based on our reliability, durability, support, and end-user value with all of the products we offer.

LACT Product Line

Glycol Product Line (for Gas Dehydration)

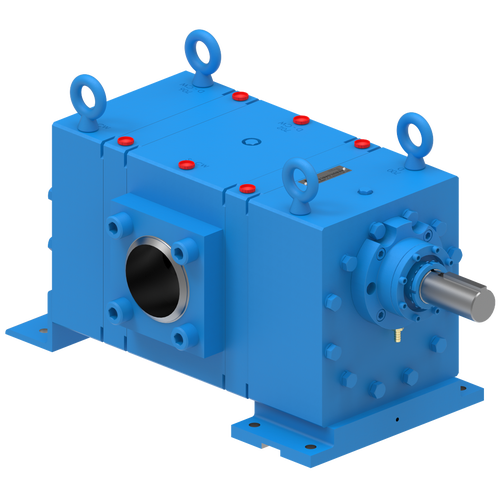

API Standards Product Line

Liquid Specific Product Line

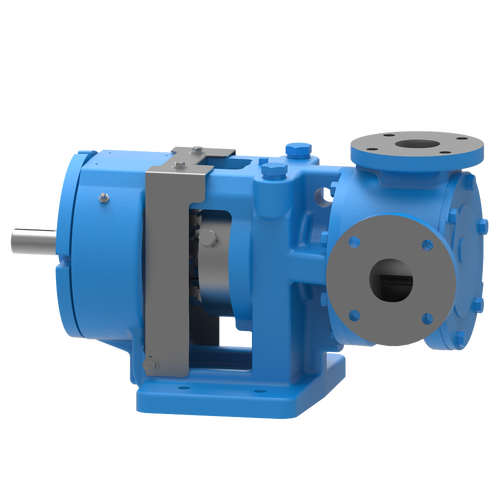

Our GB-410 Series™ is rated to handle temperatures of 350 degrees Fahrenheit to cover upset conditions. They are capable of over 225 degrees Fahrenheit differential between this pump and glycol temps.

Additionally, the robust design offers fewer moving components for robust, long-lasting field performance. New advanced hardened materials on critical internal wear surfaces enhance wear resistance and durability of dry-run, abrasives, and upset conditions. And if that wasn't enough, our pumps offer smooth flow with no pulsation-dampening equipment required.

In terms of sealing, look to our reliable mechanical seal solutions. These are less susceptible to leakage and are longer-lasting. The back pull-out design allows for easy seal changes in the field, saving you time and effort in your seal maintenance. We've made installation easy as well! Jaw Type Coupling eliminates the mess and maintenance of an oil bath. There's the option for motor mounting for easy drop-in replacement on C-Face motors up to 75 HP. And all pumps are factory tested before going out the door.

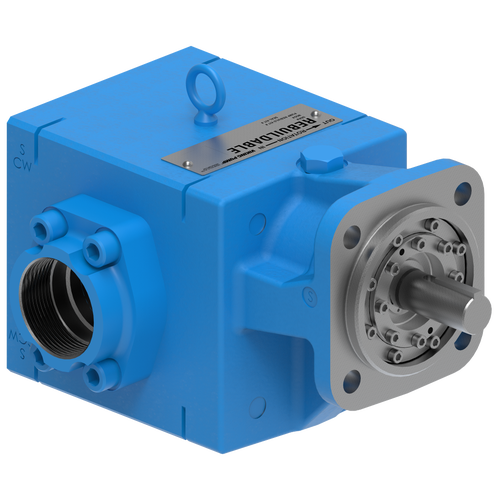

The GB-414 Series™ is dimensionally interchangeable with equivalent Gen 2 GP-414 Sizes. Compared with the GP-414, the GB-414 Series™ has new advanced materials on critical internal wear surfaces as all as enhanced wear resistance and durability to extend the pump life.

The rebuildable design of the GB-414 Series™ means that all internal wear components are easily replaceable. The simple disassembly and reassembly process saves time and money. We offer complete rebuild kits to bring your pump back to as-new operating condition. We have also improved the sealing solution, implementing type 2 bellows seal with standard 200 PSI inlet rating. This does not require the pump or motor placement to be moved for a seal change.

Already have the ports you like and dread the work it would take to change them out? With our modular port design, our standard 180° ports come with weld neck adapters to accommodate the flange of your choice. Additionally, the common port location (CPL) feature allows for installations of lower flowrate pumps when well production decreases without welcome or piping modifications on your part.

The Viking Pump Advantage

With over 110 years of experience providing positive displacement pumping solutions, Viking Pump has a rich, lengthy history of providing engineered solutions for tough applications. Dedicated sales and field support specialists are supported by a team of customer service representatives and engineers. Our knowledgeable team of application engineers is available to help with product selection and technical support. Viking Pump is a USA-based company with the vertically integrated manufacturing process