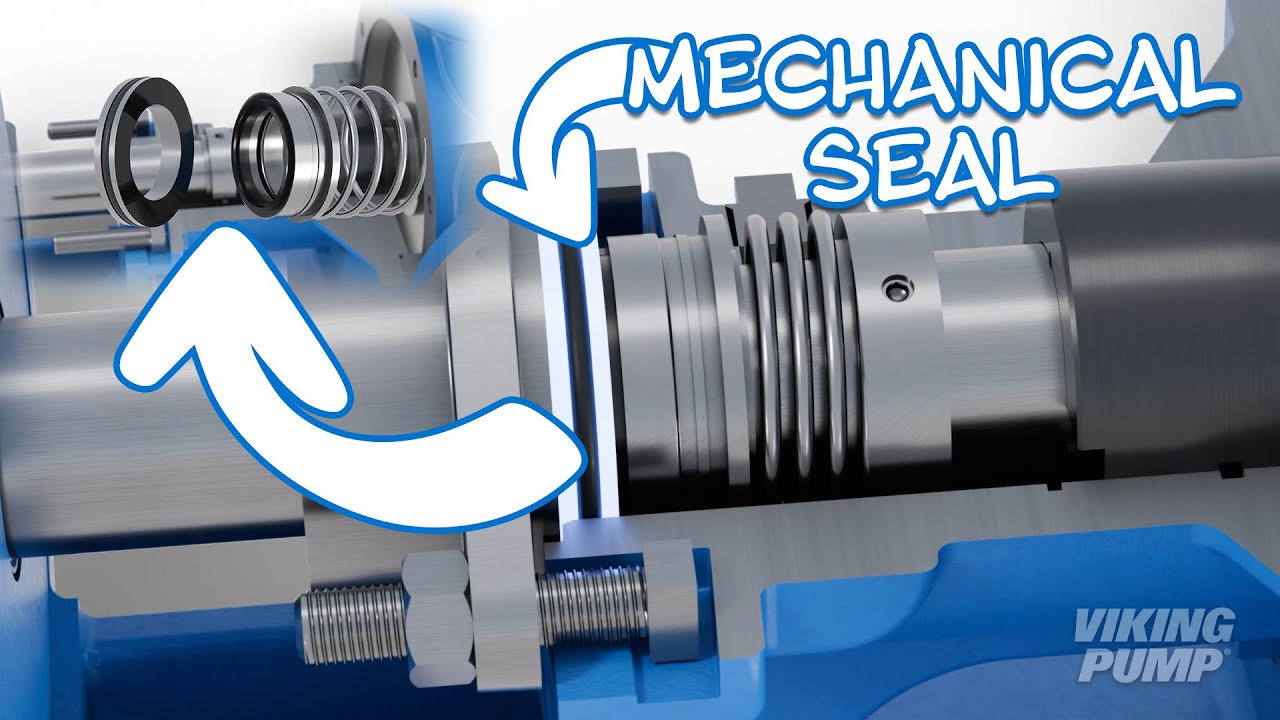

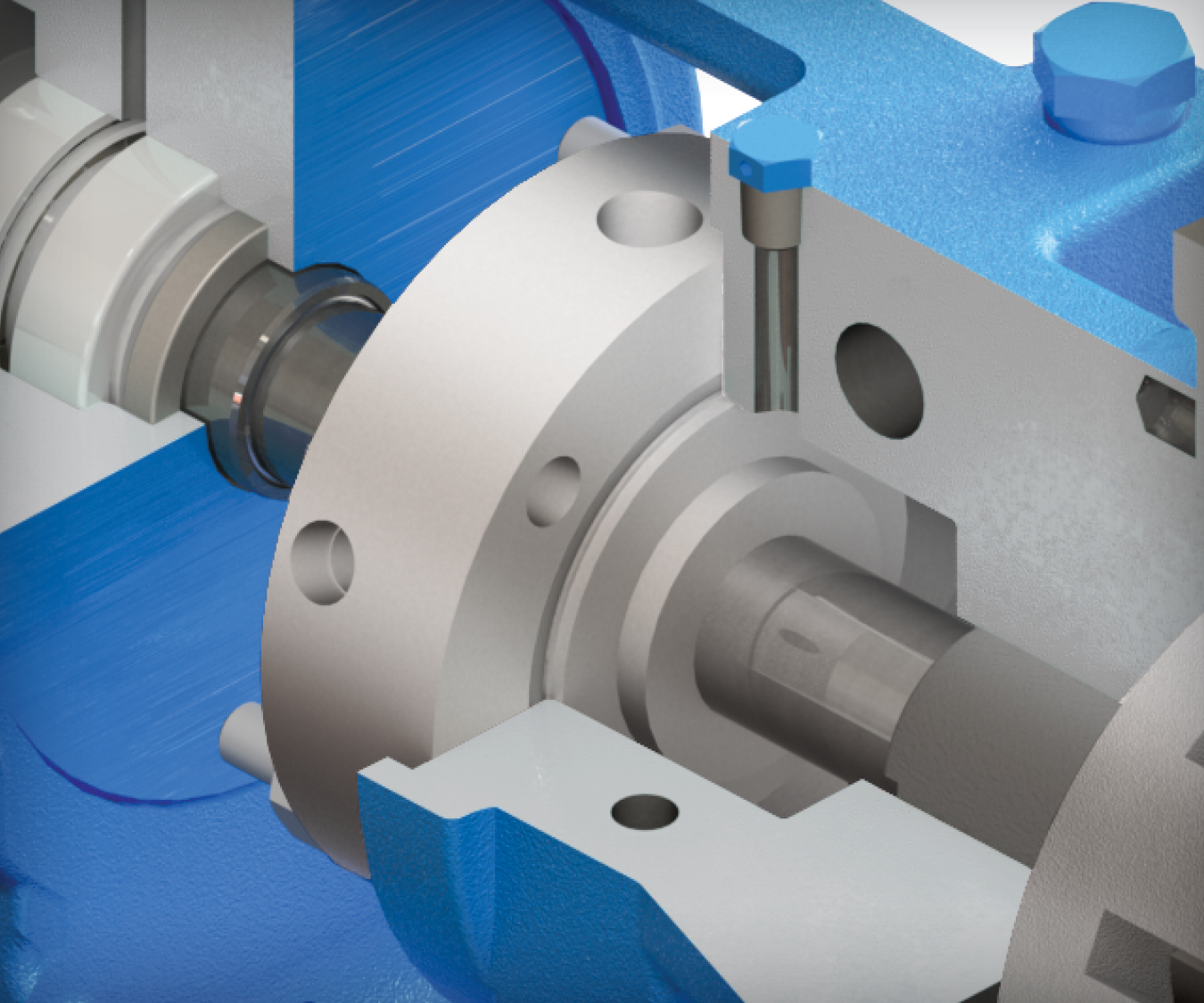

A special cartridge mechanical seal which has been designed and tested to the American Petroleum Institute’s API 682 standard

API 682 Seal

What is an API 682 seal?

An API 682 seal is a special cartridge mechanical seal which has been designed and tested to the American Petroleum Institute’s API 682 standard.

What does API mean?

API stands for the American Petroleum Institute – which maintains industry standard practices for the oil and gas industry. These standards promote safety, environmental protection, and sustainability.

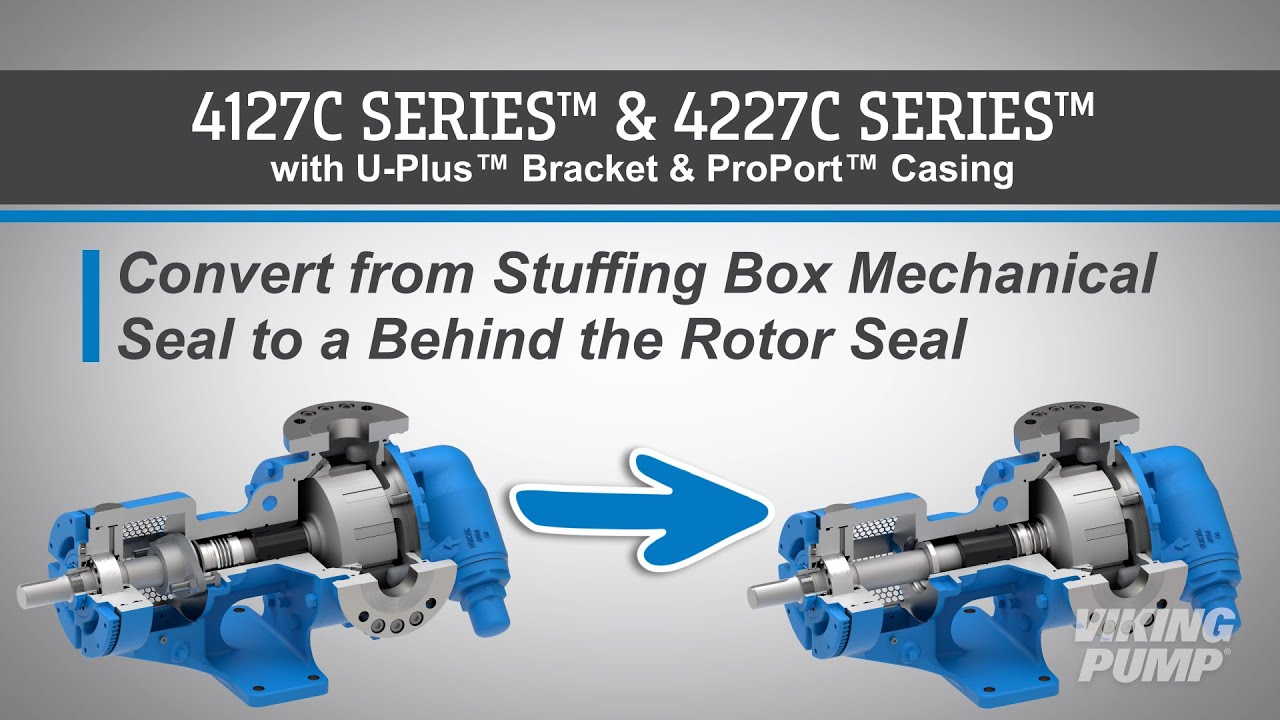

What is API 682?

API 682 is the standard used for mechanical seals (or other sealing solutions) used in centrifugal and rotary pumps that are to be applied in petroleum, natural gas and chemical industries. The purpose of the standard is to show compliance in hazardous applications where more reliable seals are required.

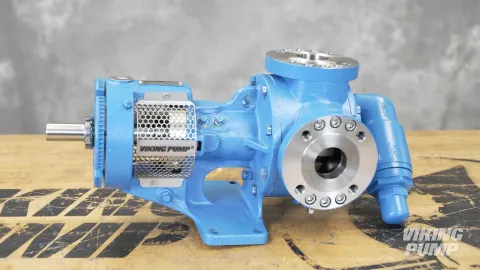

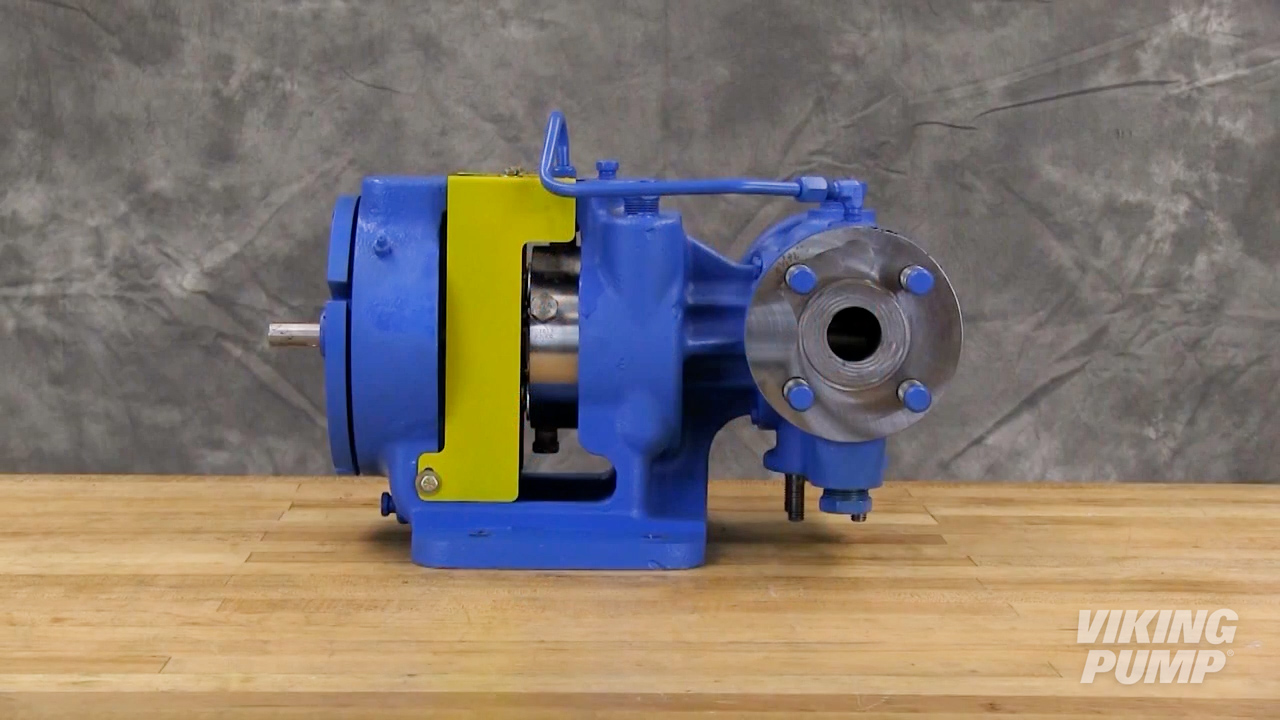

How to install an API 682 seal into a Viking pump

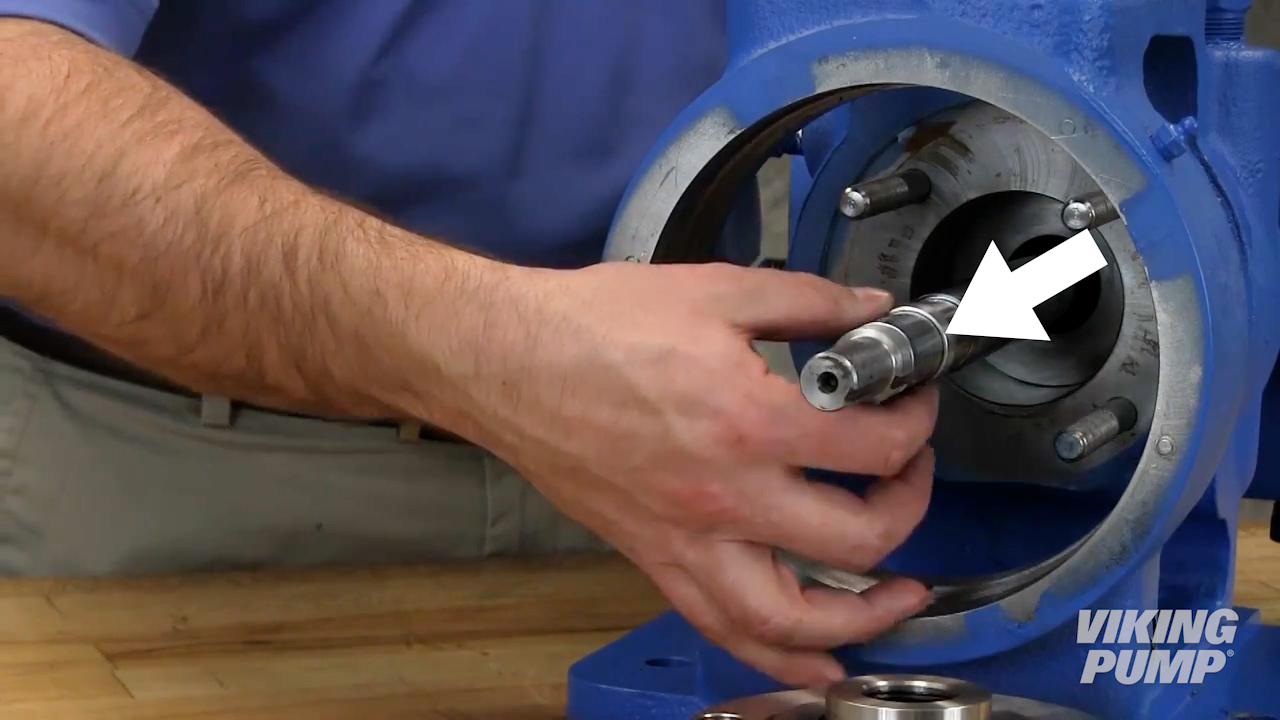

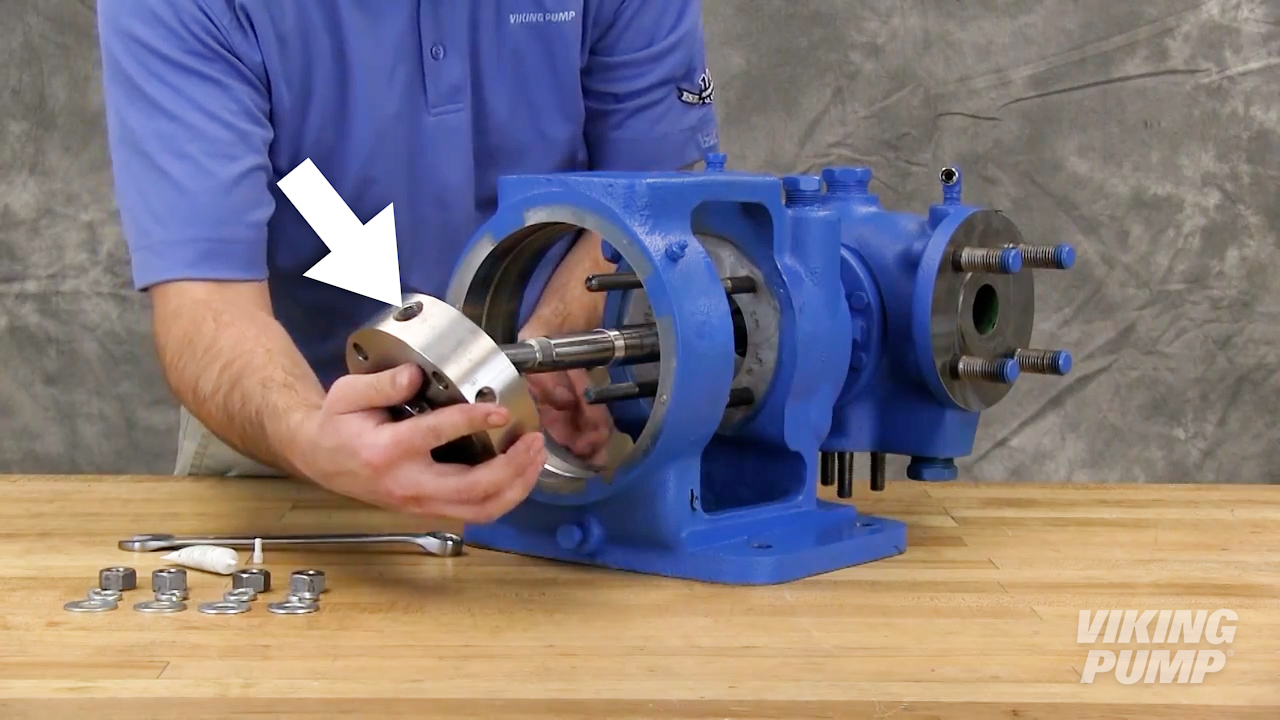

| 1. Install the tapered seal installation sleeve onto the shaft. Make sure the shaft is free of debris or wear that could damage the seal. |  |

| 2. Lubricate the shaft, installation sleeve, and the inside of the rotor member of the seal with a generous amount of light oil. |  |

| 3. Install the seal onto the shaft making sure the flush port is at the 12 o’clock position. |  |

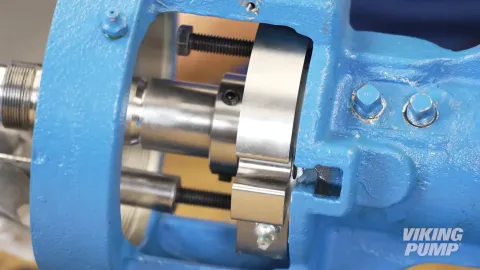

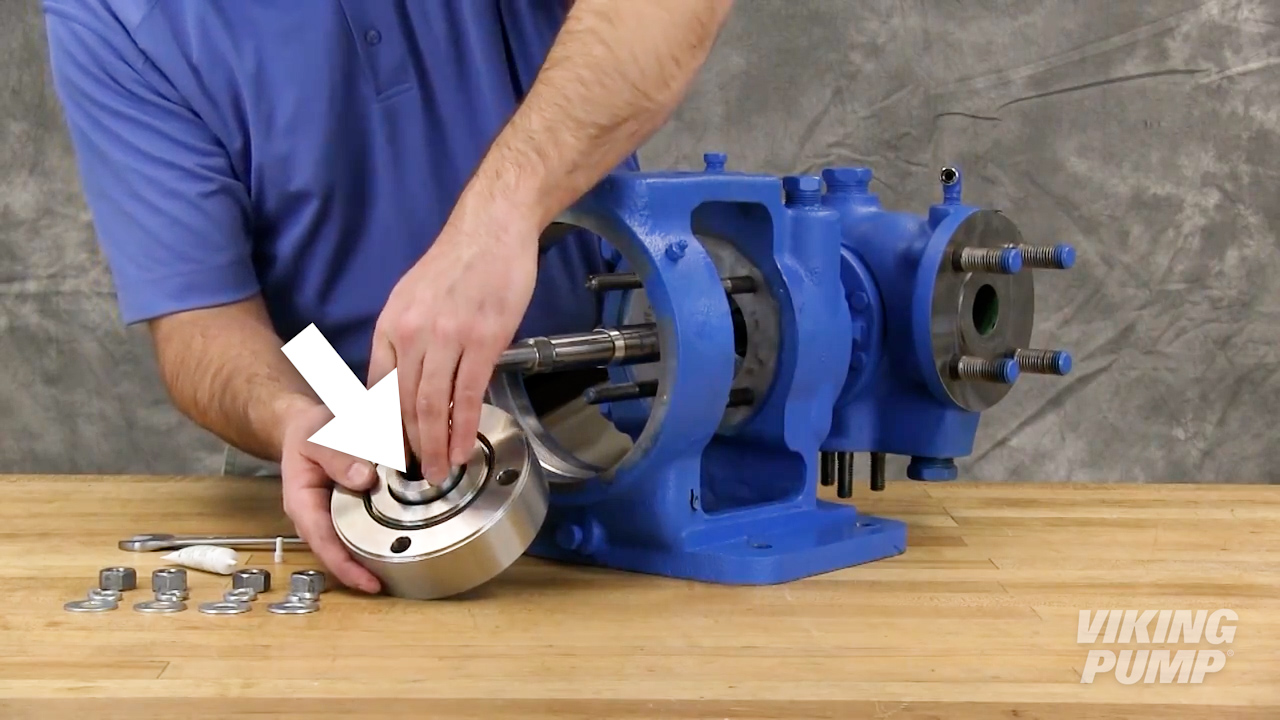

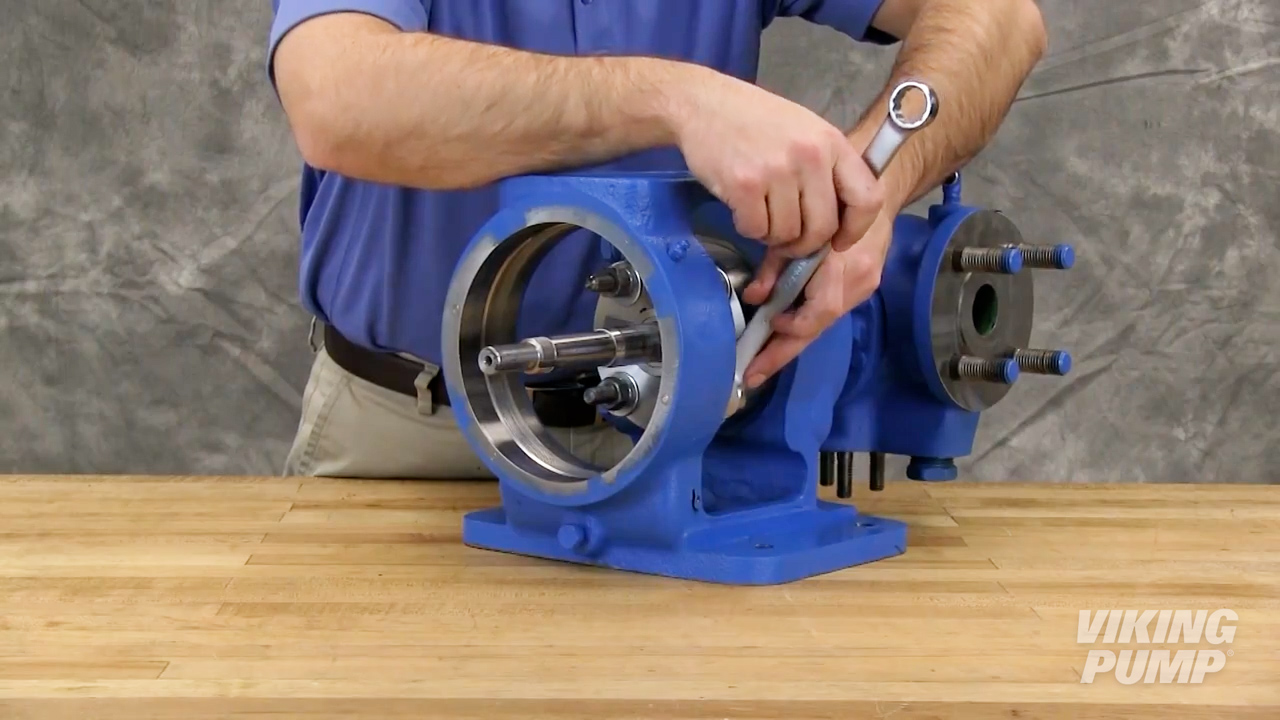

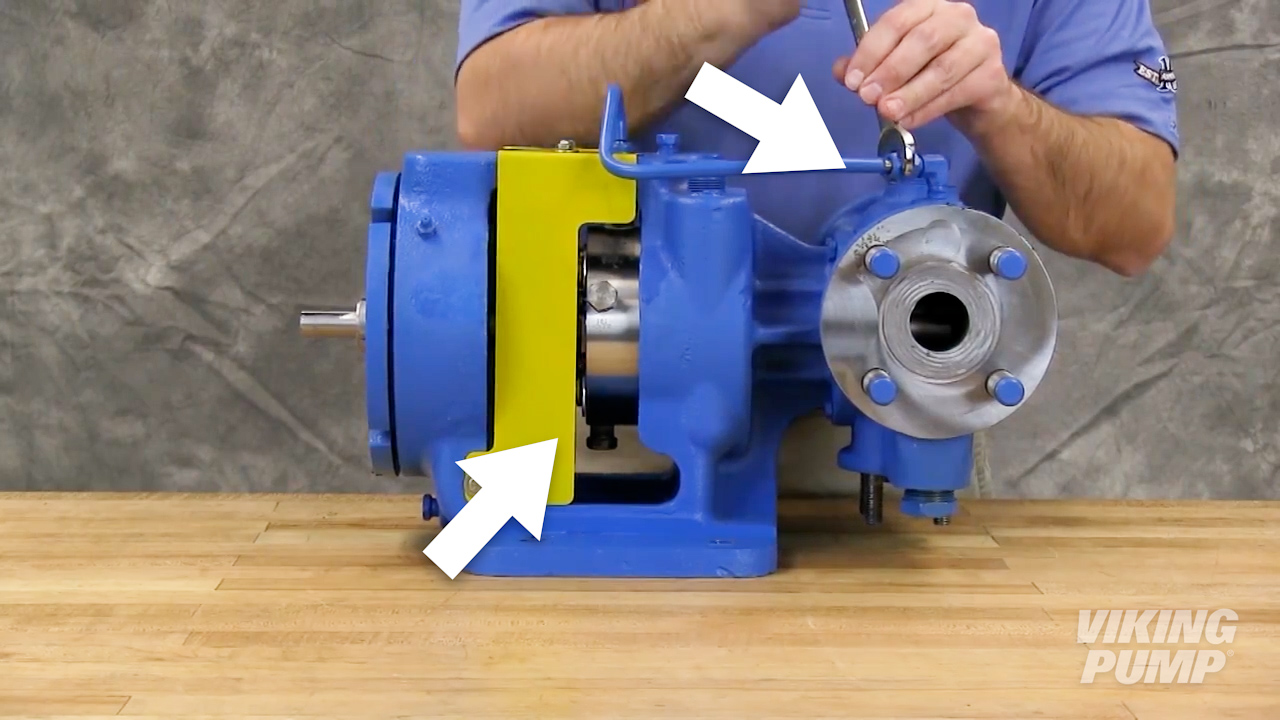

| 4. Secure the seal gland to the bracket face using the proper hardware. |  |

| Complete the rest of the pump assembly. Once end clearance for the pump is set you may proceed to final seal installation steps. | |

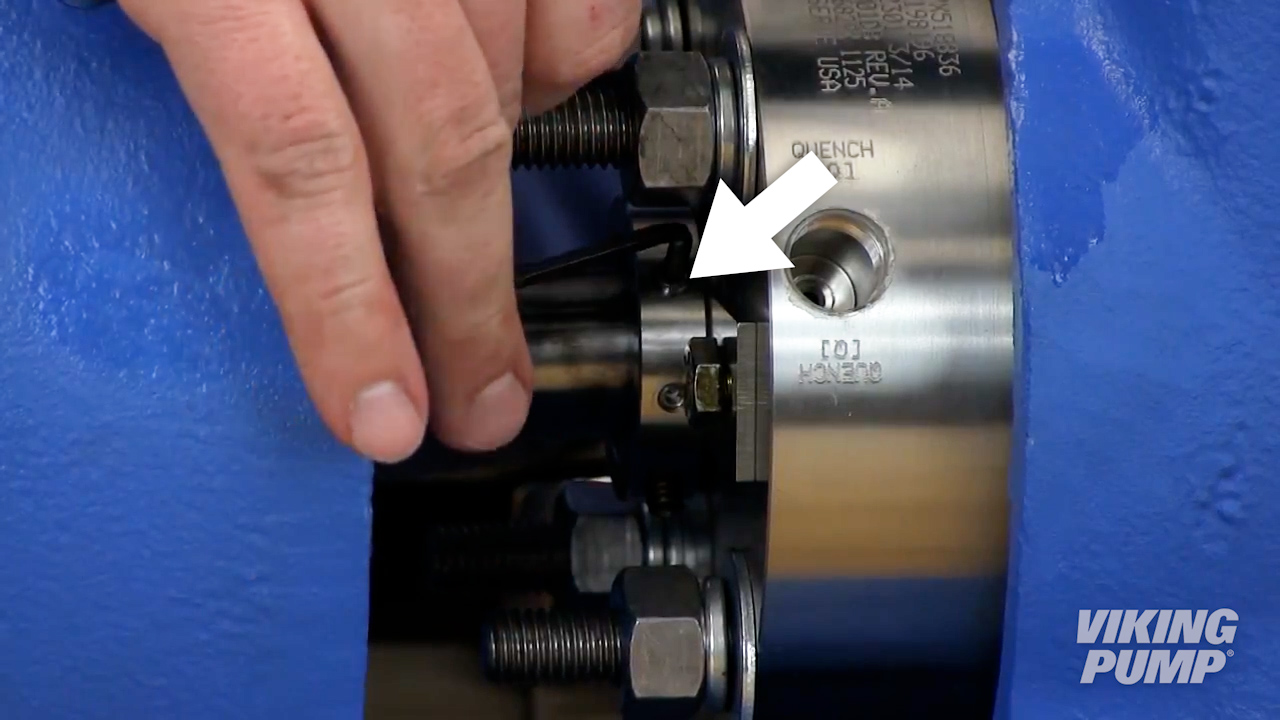

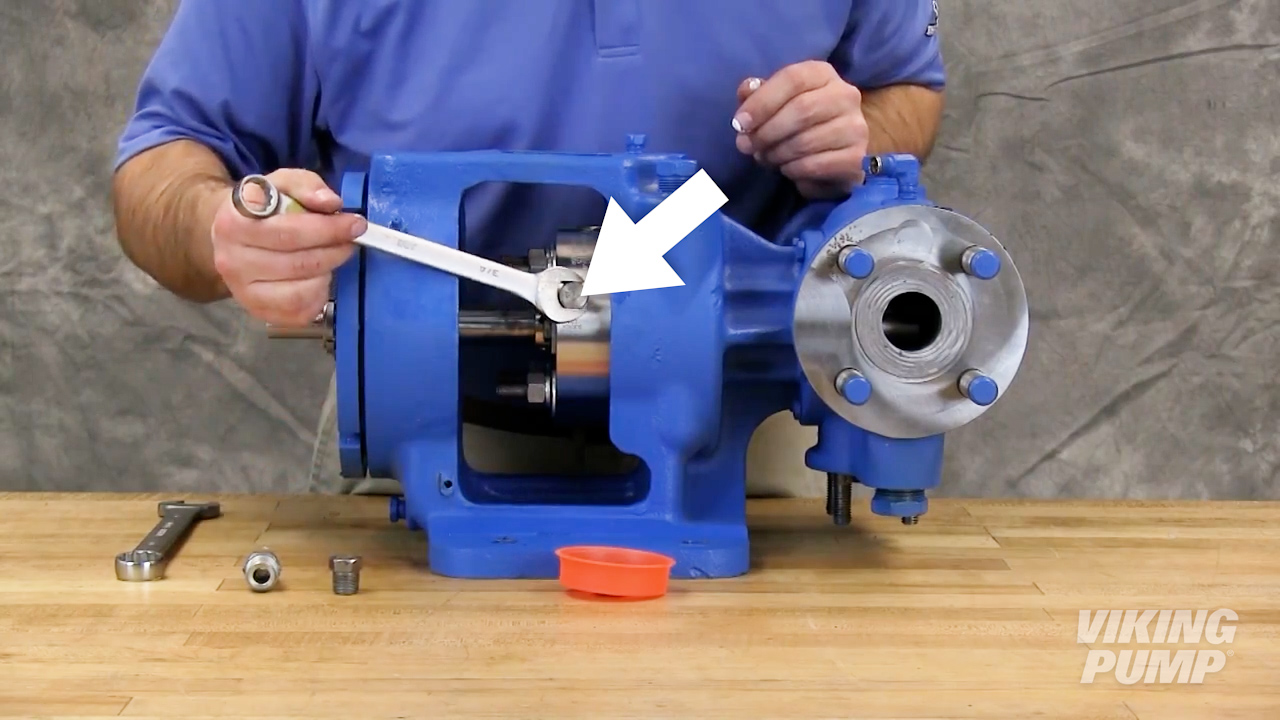

| 5. Once end clearance is set, tighten the set screws on the cartridge seal drive collar |  |

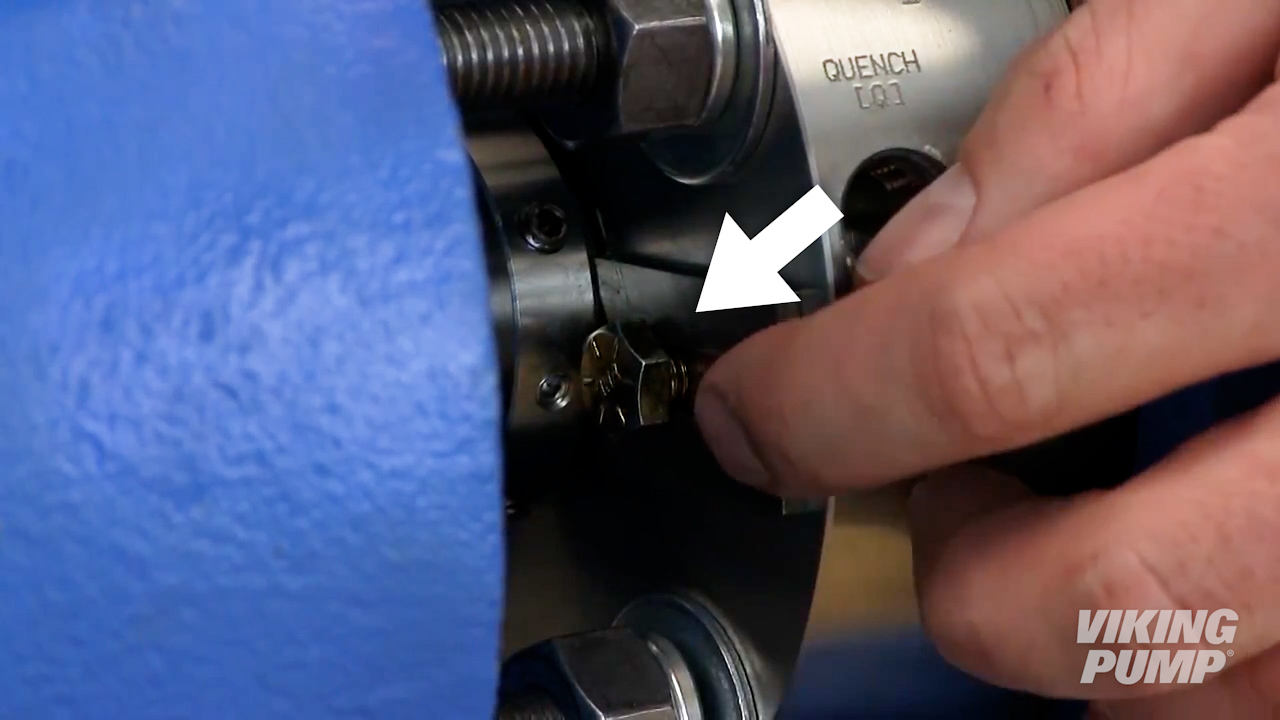

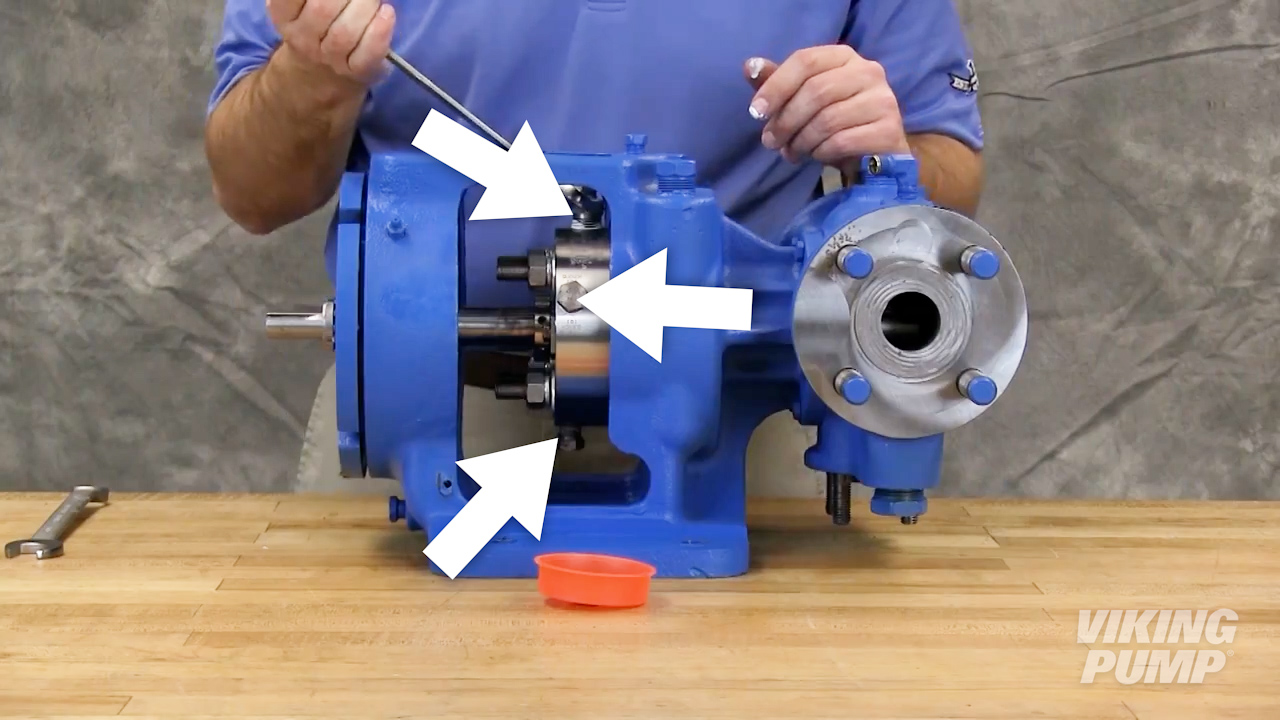

| 6. Remove or turn the centering clips to clear the seal drive collar. |  |

| 7. Ensure the pump turns freely. |  |

| 8. Install seal plugs or piping plan, using the appropriate sealing compound, into the seal gland. |  |

| 9. Install guards and barrier fluid lines as needed. |  |