Grease Transfer Pumps: Solutions for Efficient Grease Handling

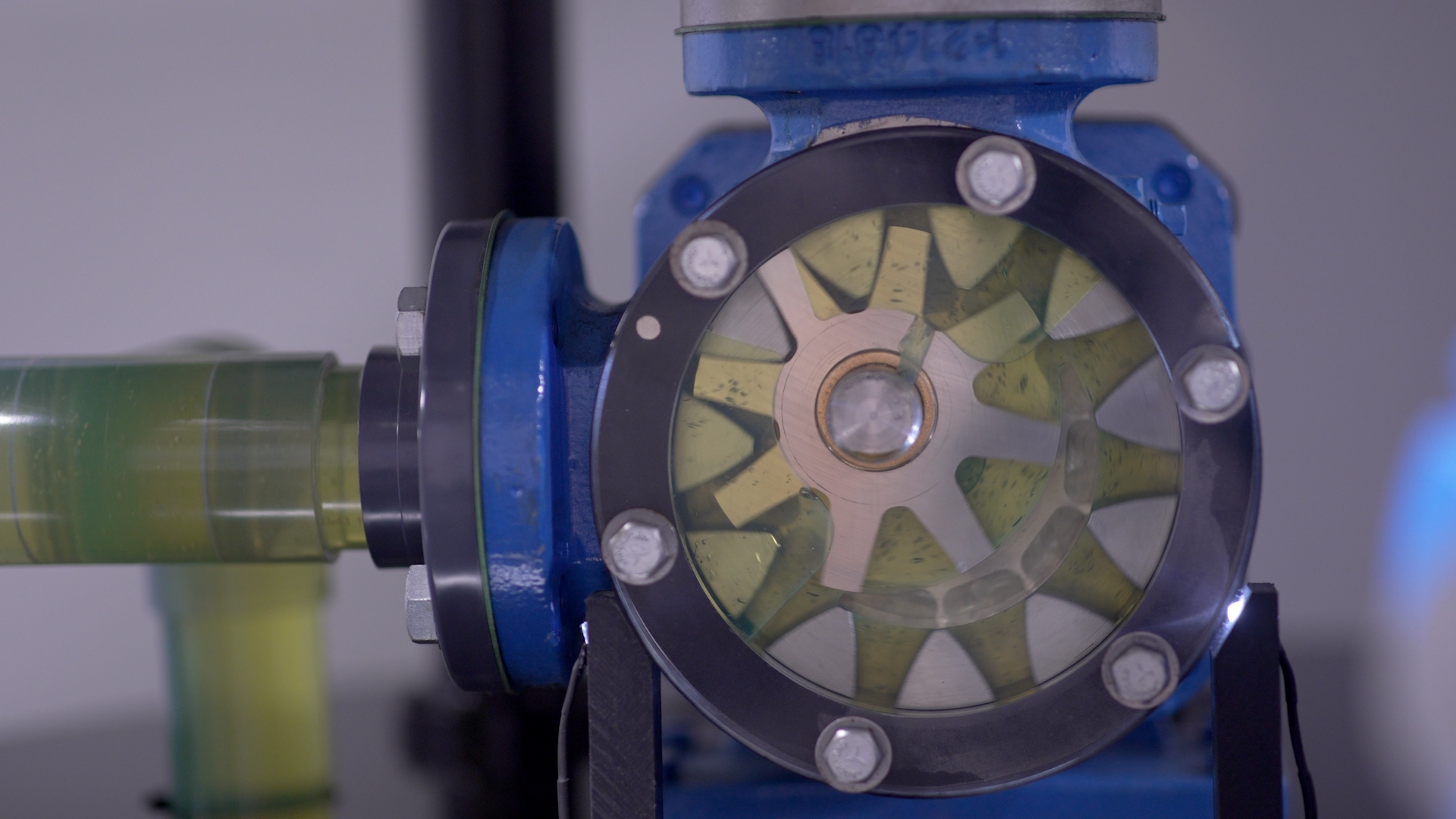

Grease is an essential component in various industries, ensuring that machinery and equipment operate smoothly. A grease transfer pump plays a crucial role in the efficient handling of grease, whether for automotive, industrial, or other applications. Here we will explore the characteristics of grease, the challenges associated with pumping it, and the grease transfer pump solutions offered by Viking Pump.

Grease is an essential component in various industries, ensuring that machinery and equipment operate smoothly. A grease transfer pump plays a crucial role in the efficient handling of grease, whether for automotive, industrial, or other applications.