In the early 20th century industrial innovation was accelerating. And as Henry Ford developed his Model T and the Wright Brothers were unlocking the secrets to manned flight, a Danish immigrant named Jens Nielsen was working on an invention of his own. Nielsen’s internal gear pump was intended to be used to lift water from his quarry but soon others found uses for his pump and the Viking Pump® company was formed.

Over the next century this remarkably simple and revolutionary principle would remain the standard for most Viking Pump model designs, but just as the car and plane have evolved, so too has the internal gear pump. The Viking Pump internal gear designs today include features far beyond Nielsen’s original design while still operating on his revolutionary internal gear principle.

The Granddad and the 32 Series™

One of the oldest internal gear pumps is on display at Viking Pump’s world headquarters. This pump, nicknamed “Granddad” (see figure 1), is very similar to a current Viking series: the 32 Series™.

In the 1920’s industry port standards were developed and incorporated into Viking pumps, eliminating the squared opening design. And the port locations were moved to the more common right-angle or opposite locations to make piping easier to install (see figure 2). Over the years, further developments were added including more sizes, optional mechanical seals, and integration of an internal pressure relief valve. Today the hallmarks of this original design can still be seen in Viking Pump’s 32 Series™ (see figure 3).

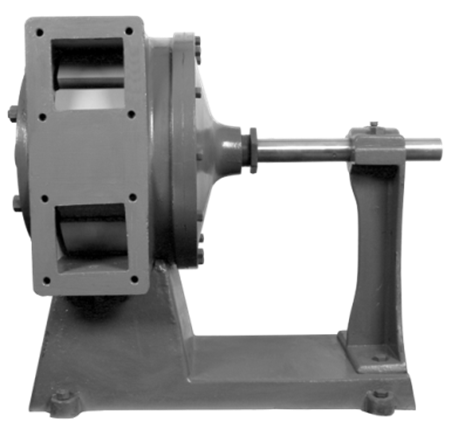

Figure 1 – “Granddad” Internal Gear Pump built circa 1904

Today Viking Pump’s 32 Series™ and evolutions thereof such as the 34 Series™ jacketed asphalt pumps and 75 Series™ motor-mounted pumps continue to be in high demand. But as applications became more demanding a need for more further innovation and development was apparent.

Truck Pumps

In the beginning, Viking pumps weren’t designed with mobility in mind. Models like the BL included heavy cast iron baseplates and large flat wheels for leather belts to power the pump (see figure 2). In the 1920’s a new market emerged for pumps mounted on trucks for delivering heating oil, road tar, and a wide variety of other liquids. These pump units needed to be more compact and capable of higher speeds and pressures than their predecessors.

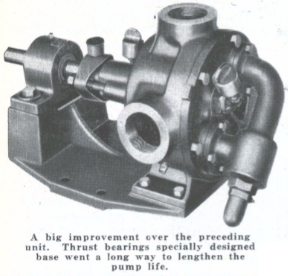

The earliest versions were little more than the standard models with a bracket which included an outboard thrust bearing (see figure 4). The addition of this shaft-mounted thrust bearing significantly lengthened the life of the pumps used for truck service.

By the 1930’s sales demand for this new design dictated the development of a new model that would include this thrust bearing as well as several other new features.

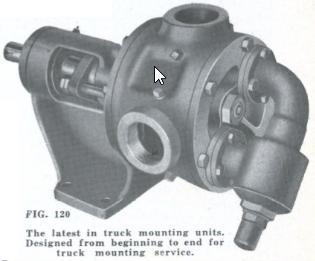

Figure 120 (later renamed the 124 Series™) represented a huge leap forward in internal gear pump design with new features which are still standard in the industry nearly a century later (see figure 5). These included:

- A sealed thrust bearing to retain the grease while keeping out dirt and water. This further protected and extended the lift of the bearings.

- An enlarged stuffing box to allow for better sealing with packing, and later the incorporation of mechanical seals

- As these pumps were pushed to new speeds and new pressures, the shaft size was increased on several of the model sizes to minimize deflection under more demanding operating conditions

- And one of the biggest changes was relocation of the foot of the pump from the casing to the bracket. This allowed the casing to now be rotated in increments of 45° to any position for ease of piping.

The 124 Series™ Revolution and Development of the 125 Series™

Transport truck manufacturers were not the only customers seeking a more robust pump option and soon demand grew for the 124 Series™ into a variety of other markets including petroleum, chemical, and food. New evolutions of the 124 Series™ were developed including versions in stainless steel, abrasive fitted constructions, and new hydraulic sizes. By the 1970’s, the 124 Series™ and its various incarnations were the flagship products in the Viking catalog.

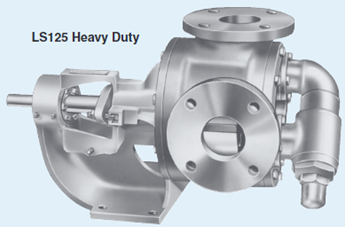

It was at this time that development started on a new version, the 125 Series™ (see figure 6). This new series included only minor changes to the old design. These included:

- A 2-piece thrust bearing assembly built into the bracket rather than a separate thrust bearing assembly.

- A cast-in catch basin in the bracket to gather any leakage past the seal rather than allowing it to immediately leak to the floor.

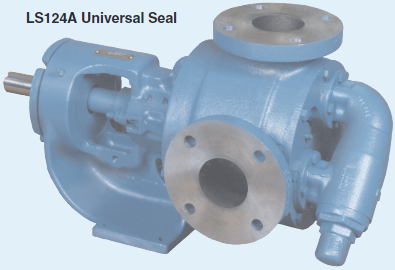

Cartridge Seals Enter the Market and the 124A Series™

In the 1980’s and into the 1990’s cartridge seals were entering the market and gaining popularity. While it was possible to install a cartridge seal into a 125 Series™ pump, doing so required special designs and disassembly to install or replace the seal. This meant development of a new bracket and pump series.

The 124A Series™, also known as the Universal Seal pump, incorporated a new bracket with an enlarged stuffing box and bearing housing. This allowed for many new advantages:

- Cartridge seals could be installed into this pump without modification

- Replacement could be done thru the bracket by removing only the bearing housing. The wetted end of the pump need not be opened to change the seal.

- A variety of seals could be offered without modification to the shaft or bracket, including packing, component mechanical seals, cartridge mechanical seals, and Viking O-Pro™ seals today.

Viking Pump’s Commitment to Customers

Anyone who’s ever owned an older car or appliance will appreciate Viking Pump’s commitment to supporting customers and pumps in the field. Tens of thousands of older models continue to provide reliable service decades after their installation. It’s important that while innovation continues, customer support is not overlooked.

It’s important to note that in the above evolution of pump models, critical parts maintained their form, fit, and function. This means that parts are still available for older 124 Series™ and 125 Series™ pumps still in operation today. This also means that upgrading to a 124A Series™ can be done without piping/system modifications and without costly changes to spare parts inventory.

Viking Pump Innovation and Evolution Continues

This blog was just a glimpse at this product family and the product iterations and developments to get where we are today. Parallel to this Viking Pump continues to evolve into even more robust and advanced lines including O-Pro™ Double O-Ring Sealed pumps, Sealless Mag Drive pumps, API 676 Fully Compliant Pumps featuring API 682 Cartridge Seals, and our newest U-Plus™ Bracket, and ProPort™ Casing features.

Our headquarters and factory may only be a mile from Jens Nielsen’s quarry, but his pump design has evolved far beyond it.