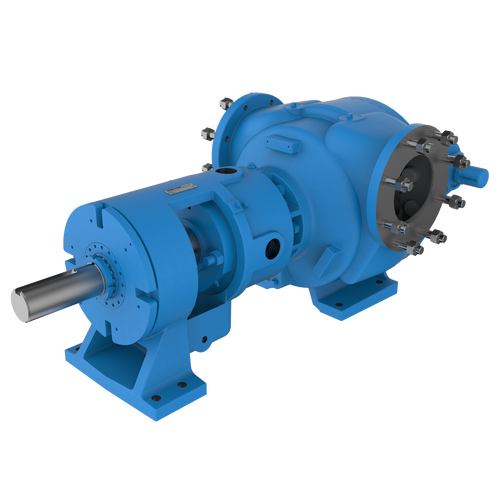

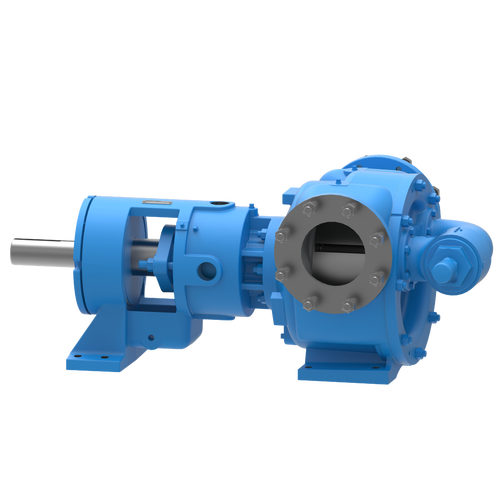

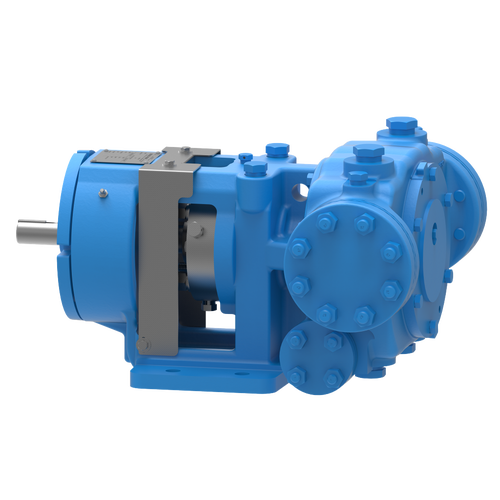

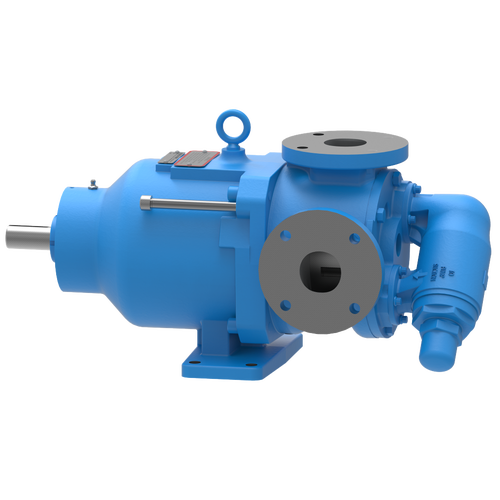

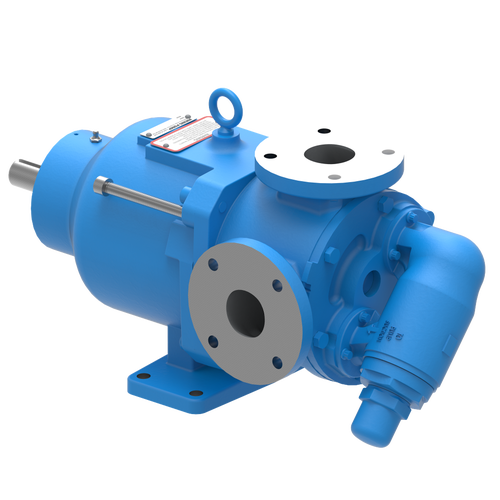

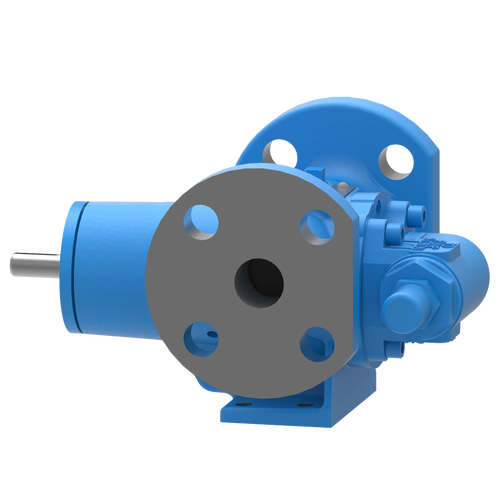

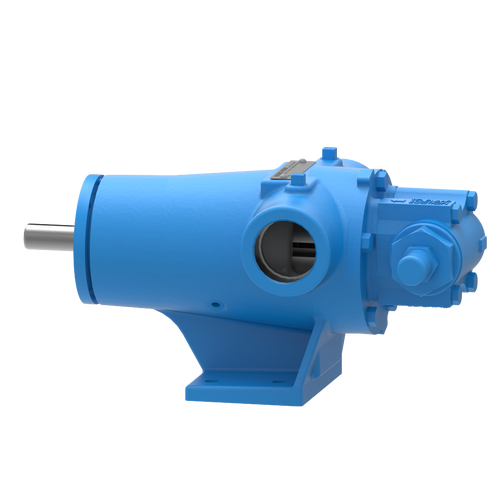

Viking Pump’s industrial pumps are the premiere positive displacement gear pump technology that covers nearly every pumping need.

With construction options that have been proven to work for light, medium, and heavy-duty applications, the versatility and popularity of positive displacement pumps lie in their relatively simple design, high efficiency, and consistent flow rates.

Industrial Gear Pumps That Perform

Utilizing time-tested technologies, our products are reliable, easy to service in the field, and uniquely engineered for a wide range of requirements. No matter the application: hot to cold, thick to thin, solids to liquid, we have the solution for you.

View all of Viking Pump's industrial gear pump solutions below to see which pump construction best matches your application.

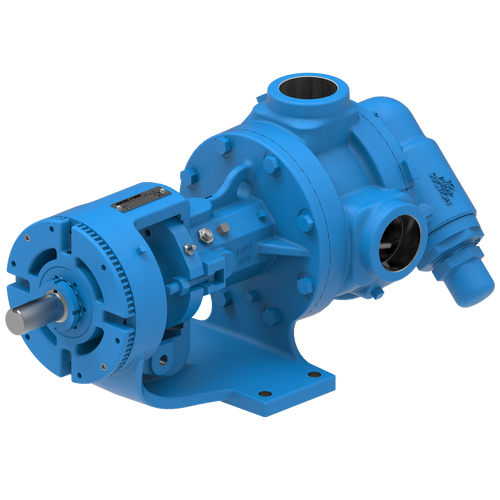

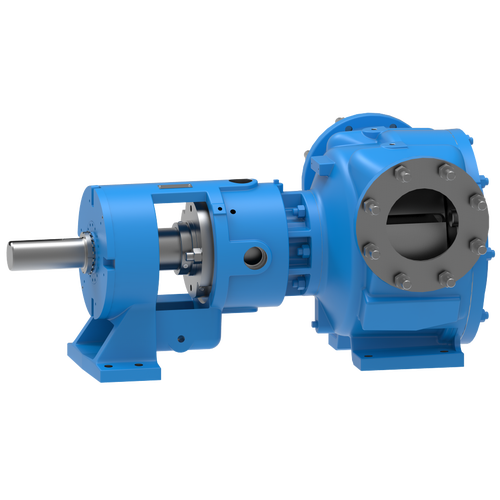

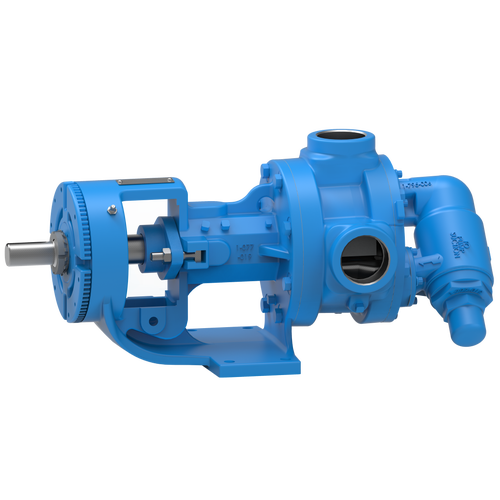

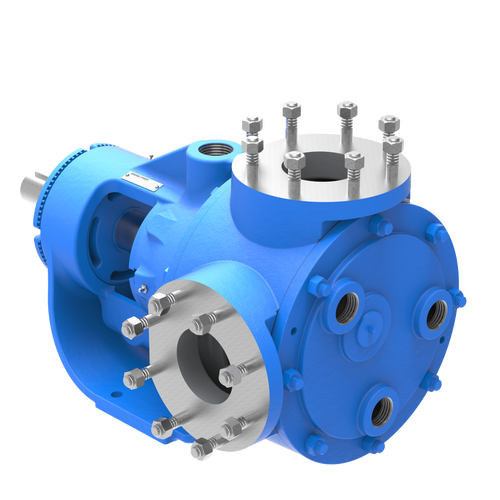

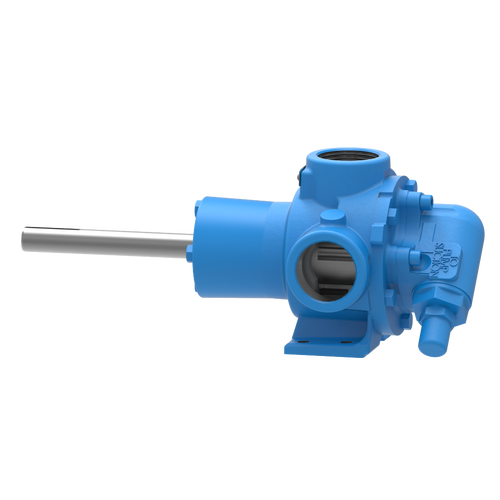

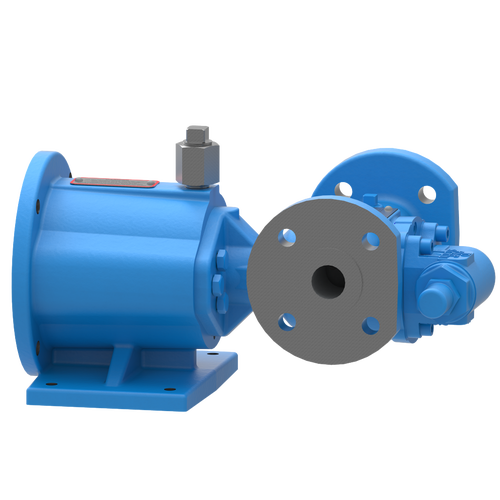

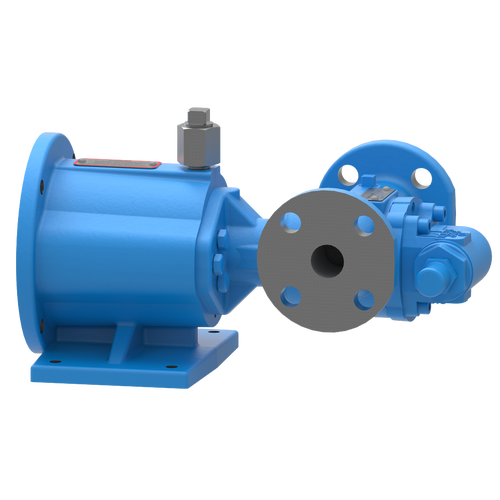

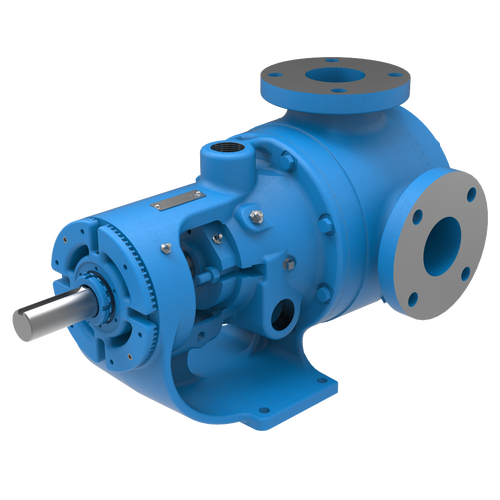

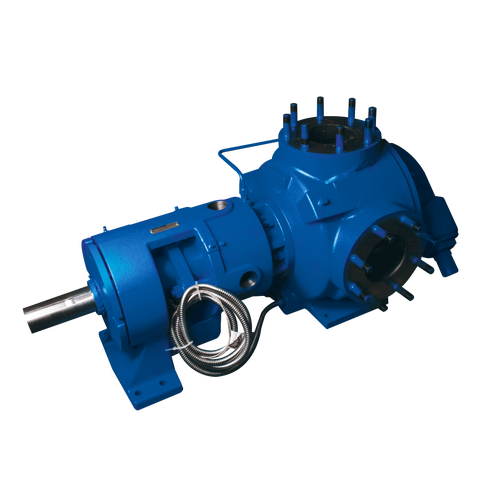

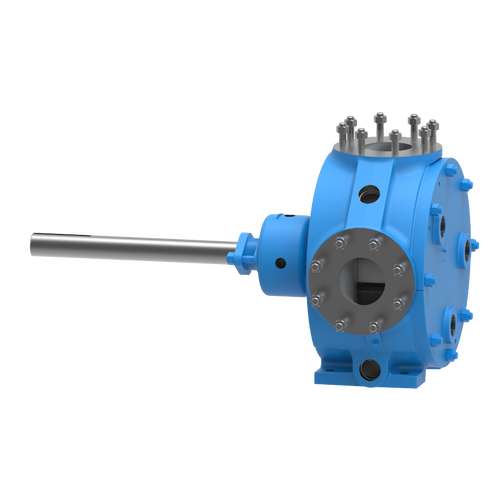

Universal Product Line

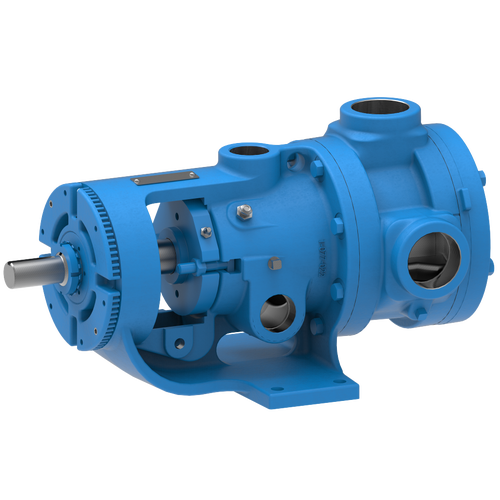

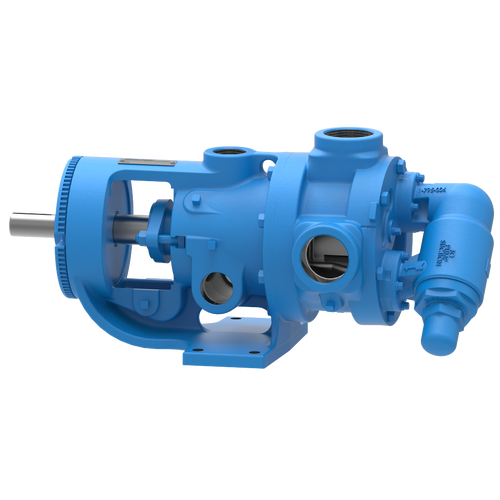

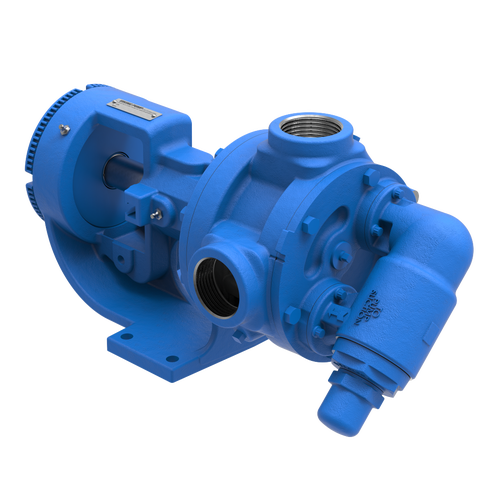

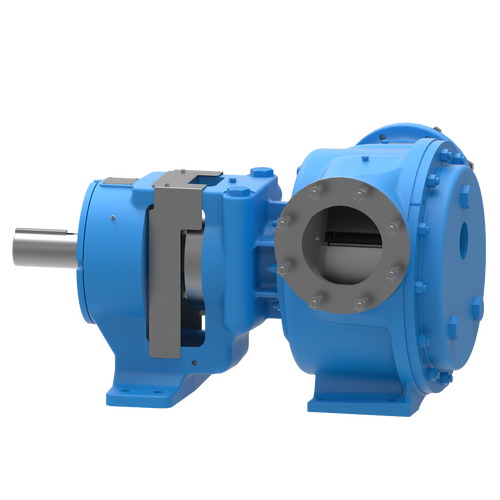

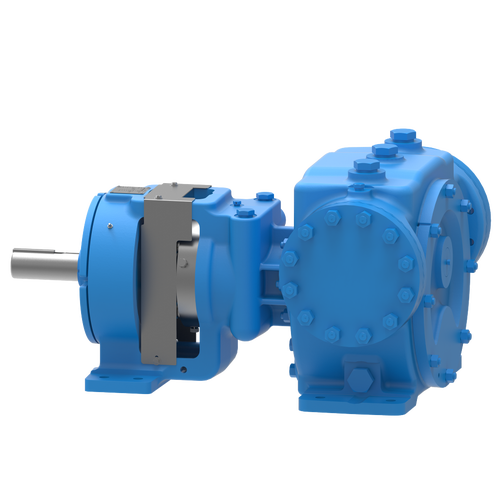

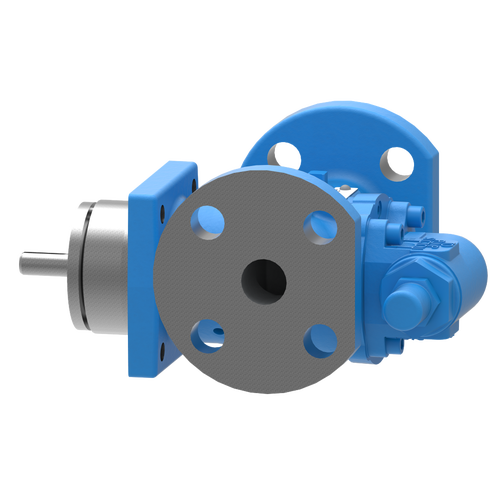

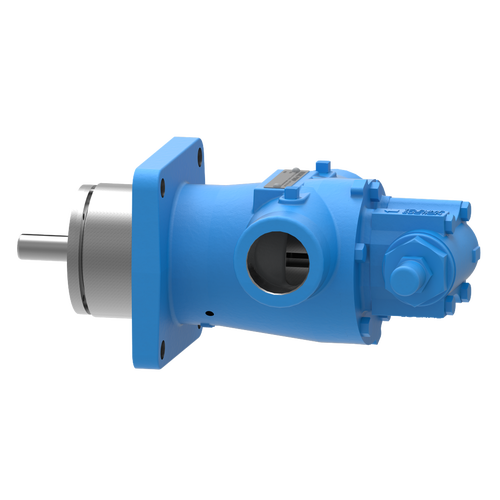

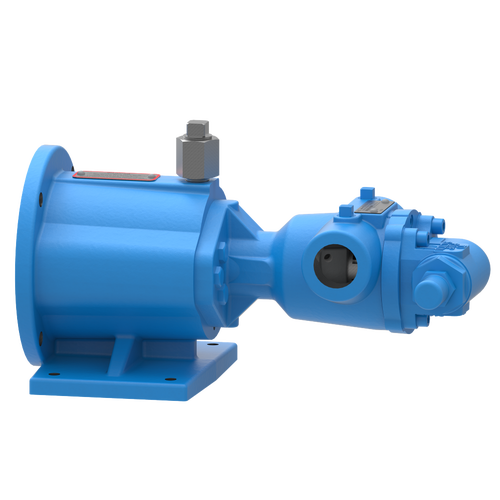

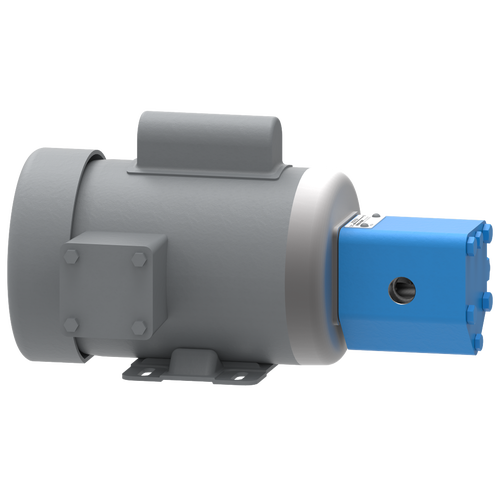

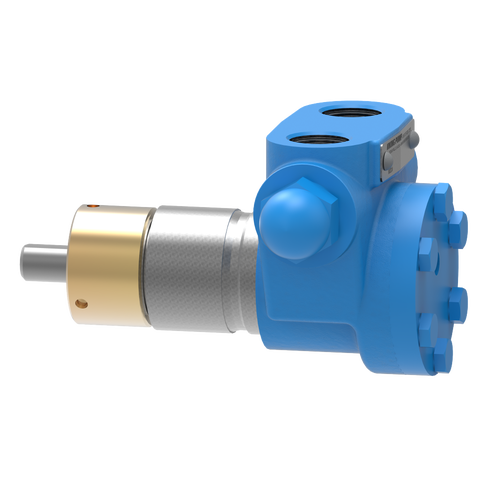

Motor Speed Product Line

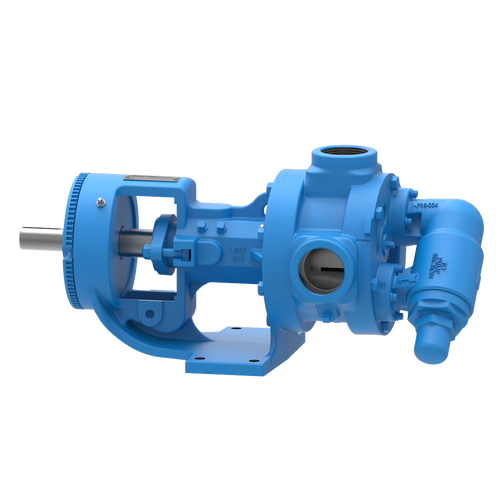

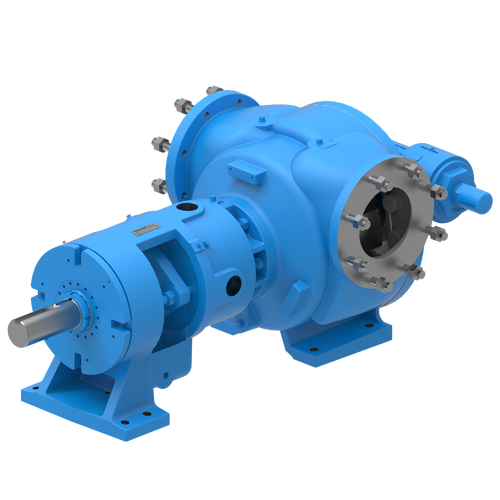

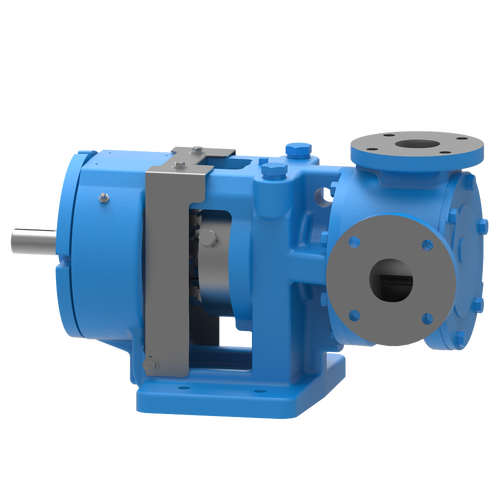

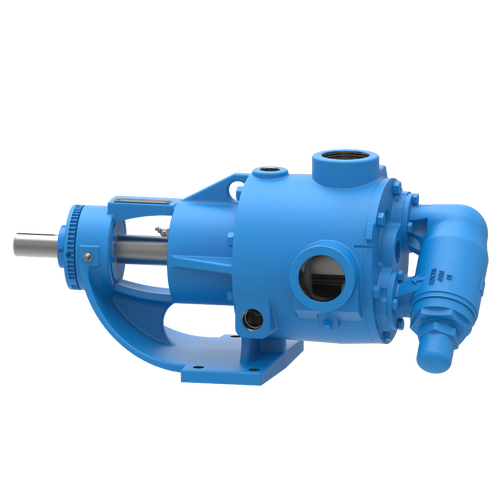

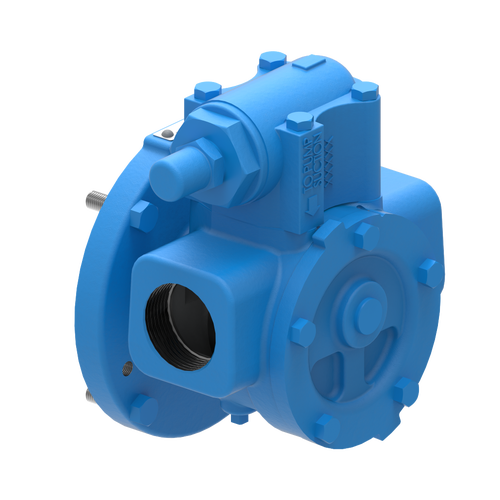

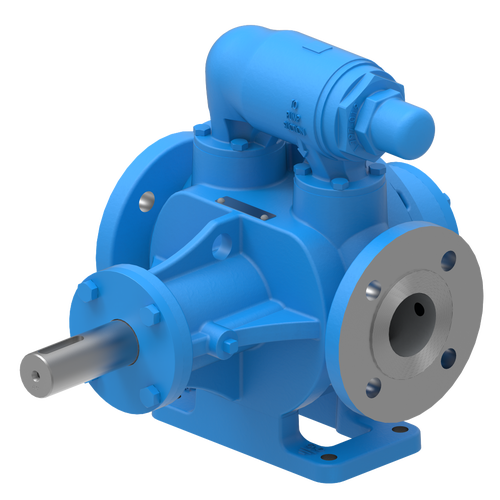

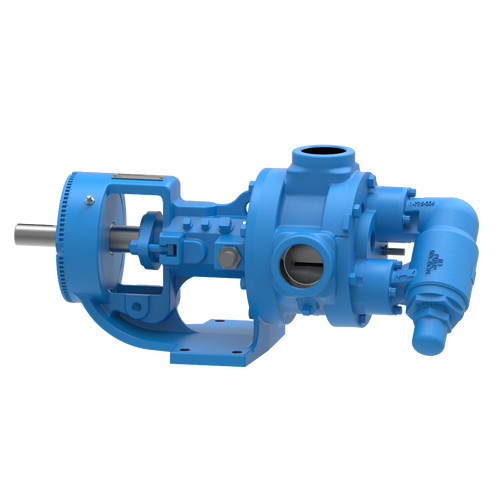

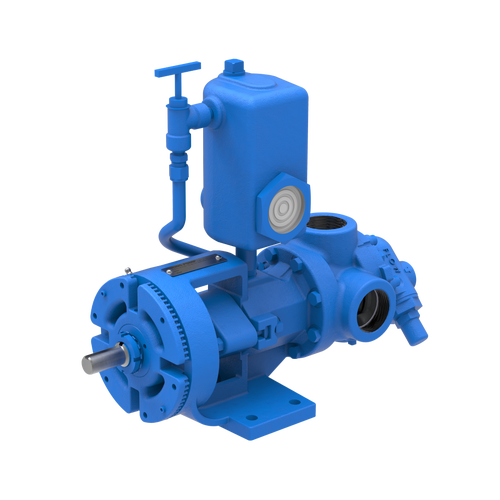

Liquid Specific Product Line

Industrial Pump FAQs

Q: Where are Viking Pumps manufactured?

A: Viking Pump operates a foundry, a 250,000+ sq. ft. machining, assembly and testing center, and an extensive product engineering and testing lab in its world headquarters in Cedar Falls, Iowa, USA. This level of vertical integration ensures maximum quality, ability to satisfy special needs, and to meet project schedules.

Q: What are industrial pumps?

A: Industrial pumps are pumps used in more general applications like all varieties of refined fuels & lubricants, resins & polymers, alcohols & solvents, asphalt & bitumen, polyurethane foam, food products, paints & inks, soaps & surfactants, and heat transfer fluids.

Q: How do industrial pumps work?

A: Viking Pump's positive displacement pumps displace liquid with each revolution of the internal pumping elements. This is done by trapping liquid between the pumping elements and a stationary casing. Depending on the application, a pump may need to be jacketed or electrically heated in order to keep a warm ambient temperature inside the pump to prevent the product from solidifying.

Q: What is the price of an industrial pump?

A: The price of a Viking industrial pump can span from as low as $500 to as high as $250,000. The price is largely dependent on the size and application in which it is being used. This is why our Viking experts work directly with you to evaluate your specific need so that we can recommend the pump that will give you the best return on your investment.

Q: Where can I purchase an industrial pump?

A: Viking industrial products are sold through our reliable distribution channel around the world. These distributors are trained in our product and can help install and service your pump. Find your area distributor by visiting https://www.vikingpump.com/contact.

Q: What are the specifications for Viking industrial pumps?

A: Specifications can be found on the pump pages after clicking on the pump of interest. Additional specifications can be find in our related literature and catalog sections, also available on the pump pages.

Q: What clearances are available on your products?

A: We offer adjustable clearances as a standard that enables handling viscosities from 28 to 2,000,000 SSU (1 to 440,00 cSt). Our internal gear products also have low shear to protect your liquids and a smooth, non-pulsating flow for accurate measurement or metering.

Q: Aren't PDP pumps prone to leaking?

A: Many of our models come with our patented O-Pro® Seal which dramatically reduces leaks. O-Pro® Seals utilize a series of O-rings to create a robust seal and lubrication chamber, all in one. O-Pro® Barrier seal functions as both a seal and bracket bushing; O-Pro® Cartridge & Guard seals are simple retrofit options. This means a safe, clean environment for your staff and money saved from lost product.