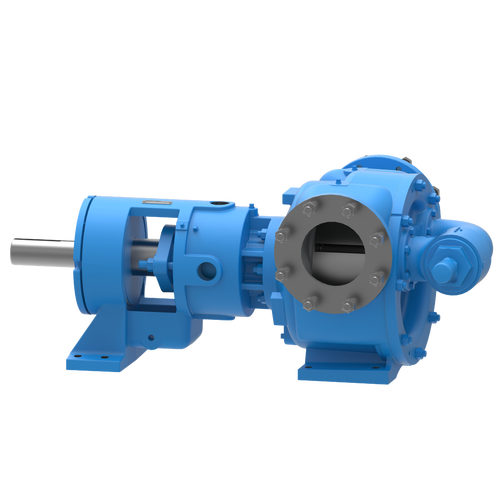

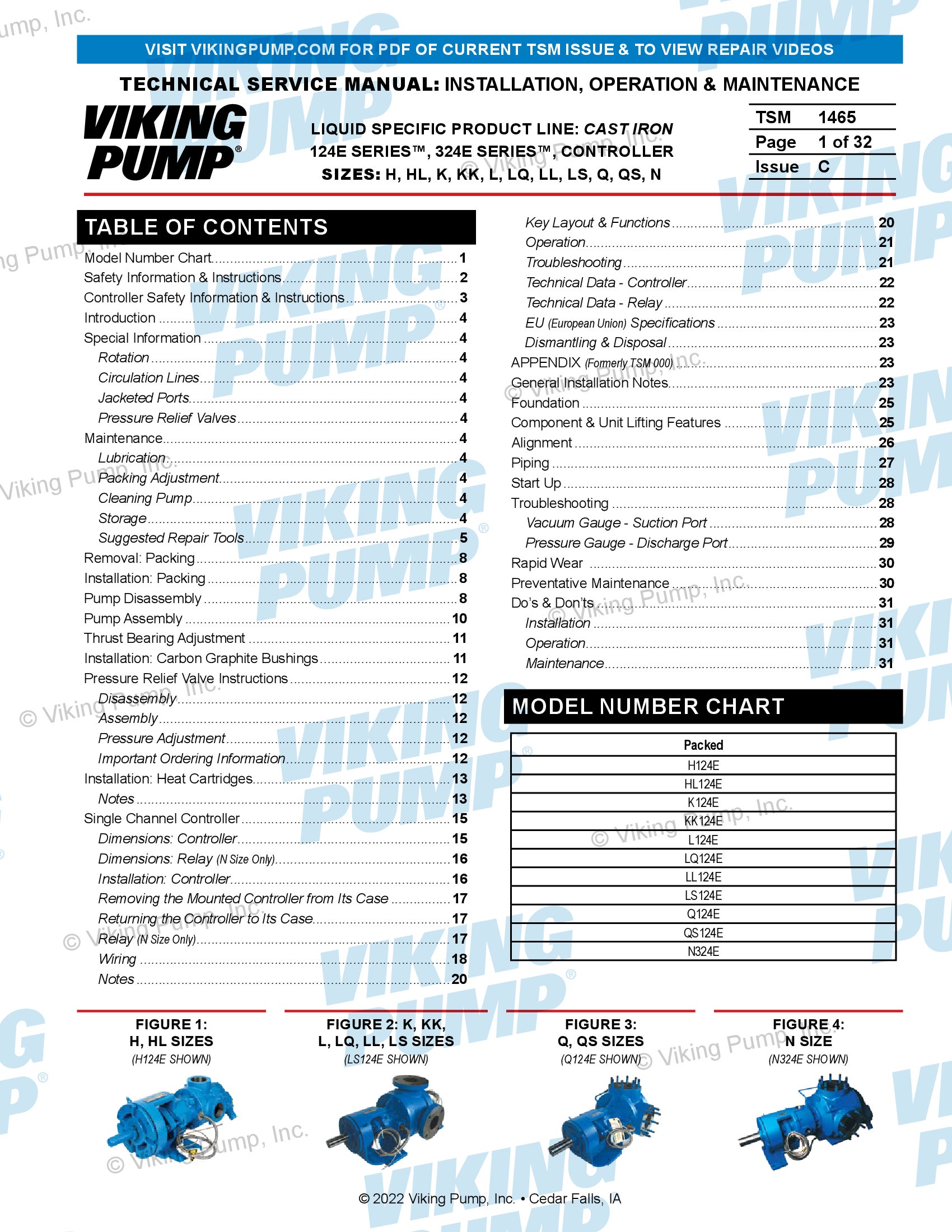

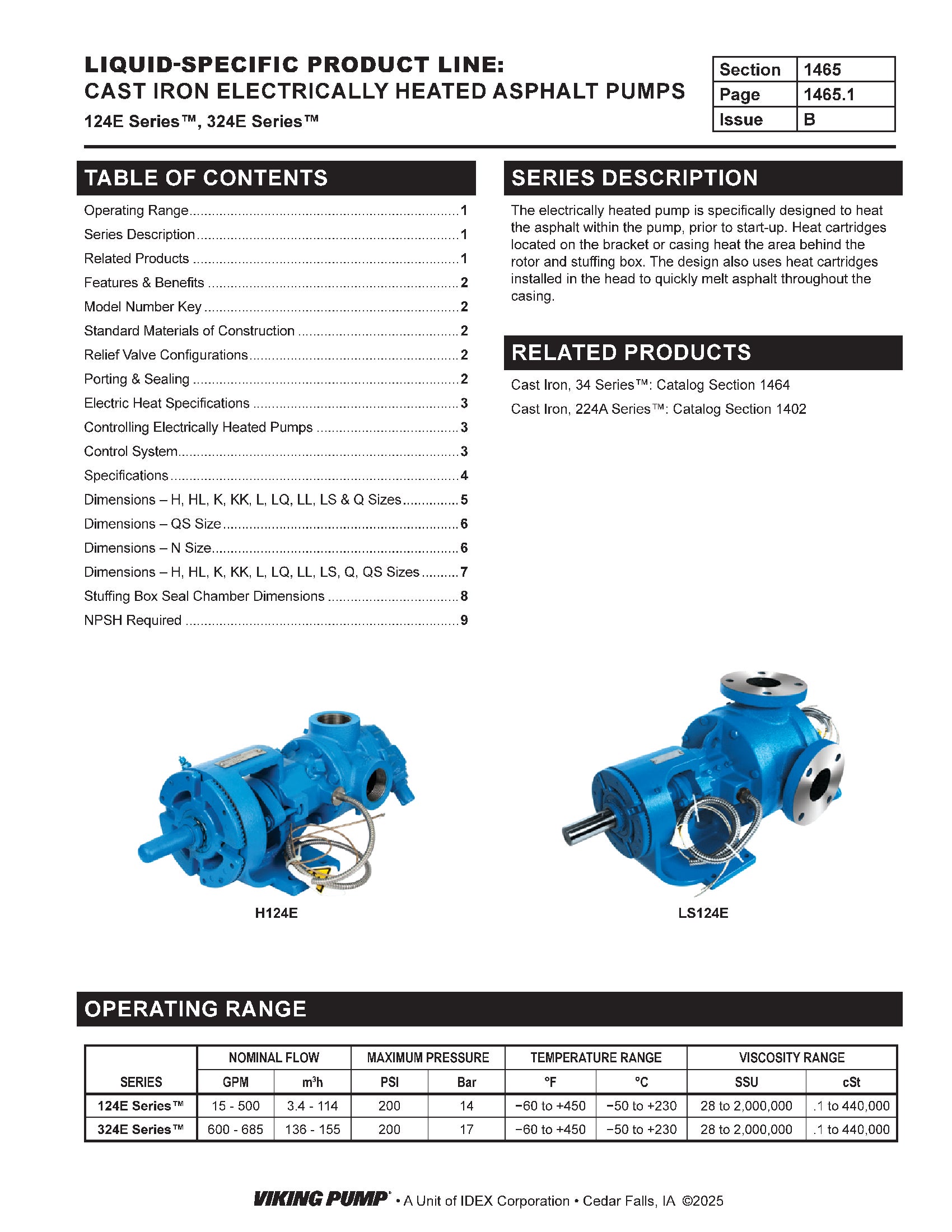

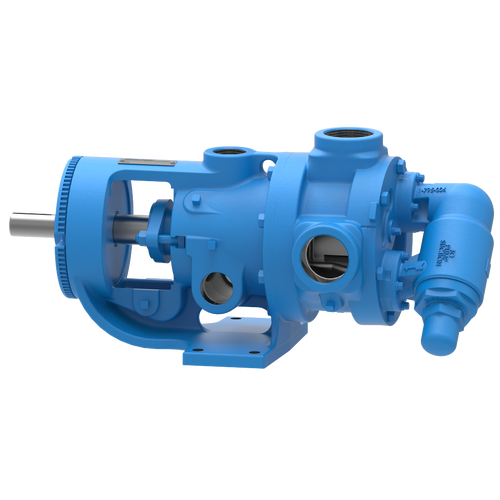

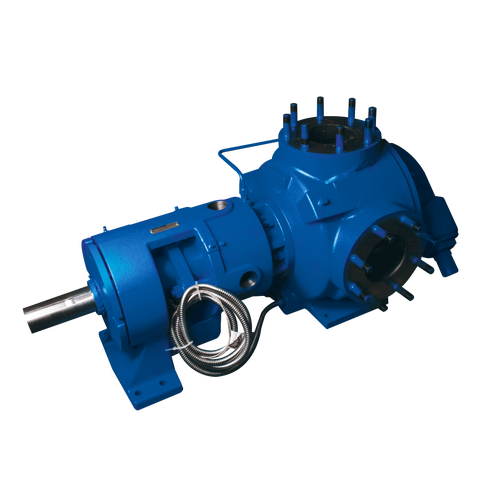

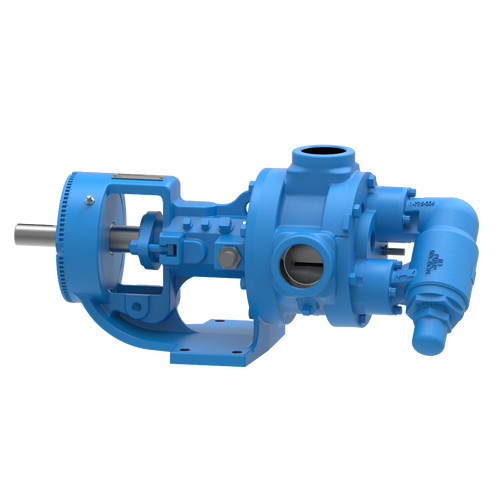

The 124E Series™ internal gear electric heated pump is the perfect solution for your asphalt needs because it warms the asphalt within the pump prior to startup. It can hold capacities up to 500 GPM (114 m³/h).

Features & Benefits

- Reduced installation & maintenance expense

- Lower installation costs in remote locations when steam or hot oil is not available or requires long piping runs

- Provides expansion flexibility

- Eliminates the hot oil or steam system

- Simplified service due to the lack of hot oil or steam connections

- Reduce energy costs

- Eliminates heat loss through piping

- Reduces environmental costs by eliminating hot oil or steam piping

Capacity

0 to 500 GPM

0 to 114 m³/h

Viscosity

28 to 2,000,000 SSU

1 to 440,000 cSt

Pressure

to 200 PSI

to 14 Bar

Temperature

-60 to +450 °F

-51 to +230 °C

Options

Porting

Drives

Mounting

Sealing

Specifications

| Model | Standard Port Size (In / mm) | Nominal Pump Rating (GPM) | Nominal Pump Rating (m3/h) | Maximum RPM | Maximum Pressure PSI | Maximum Pressure BAR |

|---|---|---|---|---|---|---|

| H124E | 1.5 / 38 | 15 | 3.4 | 1750 | 200 | 14 |

| HL124E | 1.5 / 38 | 30 | 6.8 | 1750 | 200 | 14 |

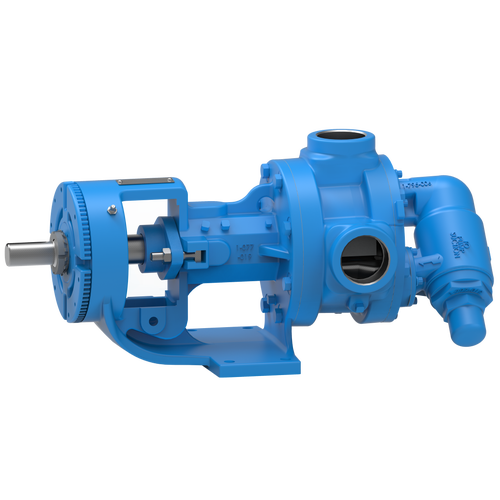

| K124E | 2 / 50 | 75 | 17 | 780 | 200 | 14 |

| KK124E | 2 / 50 | 100 | 23 | 780 | 200 | 14 |

| L124E | 2 / 50 | 135 | 30 | 640 | 200 | 14 |

| LQ124E | 2.5 / 65 | 135 | 30 | 640 | 200 | 14 |

| LL124E | 3 / 76 | 140 | 32 | 520 | 200 | 14 |

| LS124E | 3 / 76 | 200 | 45 | 640 | 200 | 14 |

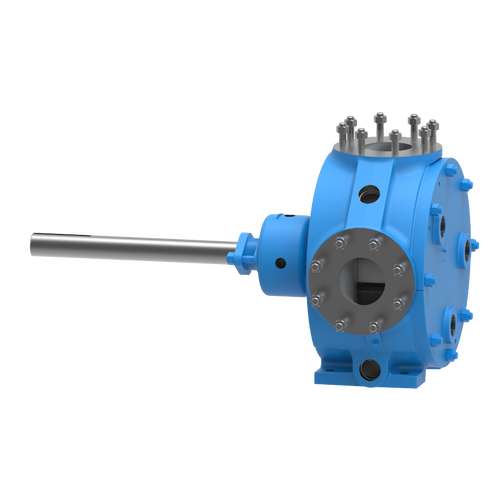

| Q124E | 6 / 150 | 300 | 68 | 520 | 200 | 14 |

| QS124E | 6 / 150 | 500 | 114 | 520 | 200 | 14 |

Videos

Asphalt Cement

Clean asphalt contains no fillers and is an oil based liquid. It is primarily used in paving roads, waterproofing liquids, and paints. Typically they are handled at elevated temperatures to reduce the viscosity of the asphalt. The pump needs a source of heat like jacketing or electric heat to prevent the product from solidifying in the pump.

Asphalt Emulsions

Emulsions are asphalt suspended in a mixture with water or other liquids. This is done to ease the application of the asphalt. Uses would be crack filling, coating roadways, or waterproofing. These emulsions are shear sensitive and must be handled with care.

Filled Asphalt

Filled asphalts contain particulate used in the liquids’ end applications. Examples of this would be roofing materials and hot mix plants. Typically they are handled at elevated temperatures to reduce the viscosity of the asphalt mixture. The pump needs a source of heat like jacketing or electric heat to prevent the product from solidifying in the pump.

-

Repair Resources

Viking Pump Universal Seal Series with Packing Seal Disassembly, Repair & Reassembly

-

DRAWINGS

H124E Plain Head - 1.5" NPT RH PDF

STEP

HL124E Plain Head - 1.5" NPT RH PDF

STEP

H124E Relief Valve - 1.5" NPT RH PDF

STEP

HL124E Relief Valve - 1.5" NPT RH PDF

STEP

K124E with Plain Head - 2" NPT RH PDF

STEP

KK124E with Plain Head - 2" NPT RH PDF

STEP

K124E with Relief Valve - 2" NPT RH PDF

STEP

KK124E with Relief Valve - 2" NPT RH PDF

STEP

L124E with Relief Valve - 2" NPT RH PDF

STEP

LQ124E with Relief Valve - 2.5" Class 125 ANSI RH PDF

STEP

LL124E with Plain Head - 3" Class 125 ANSI RH PDF

STEP

LL124E with Relief Valve - 3" Class 125 ANSI RH PDF

STEP

LS124E with Relief Valve - 3" Class 124 ANSI RH PDF

STEP

L124E with Plain Head - 2" NPT RH PDF

STEP

LQ124E with Plain Head - 2.5" Class 125 ANSI RH PDF

STEP

LS124E with Plain Head - 3" Class 124 ANSI RH PDF

STEP

Q124E with Plain Head - 4" Class 125 ANSI RH PDF

STEP

Q124E with Relief Valve - 4" Class 125 ANSI RH PDF

STEP

QS124E with Plain Head - 6" Class 125 ANSI Opposite PDF

STEP

QS124E with Relief Valve - 6" Class 125 ANSI Opposite PDF

STEP