Like any job, you need the proper tools to do it well – and the same is true for repairing or servicing positive displacement gear pumps. Below are helpful hand tools that Viking's pump experts recommend having ready for quick and efficient industrial pump repair & servicing to get you back up and running.

A reliable ratchet and socket set- in both SAE and metric- are needed for tightening and removing pieces such as cap screws, nuts, or lock nuts depending on the size of Viking Pump you are working on. Having access to deep bore sockets is a plus for those larger pump sizes, too.

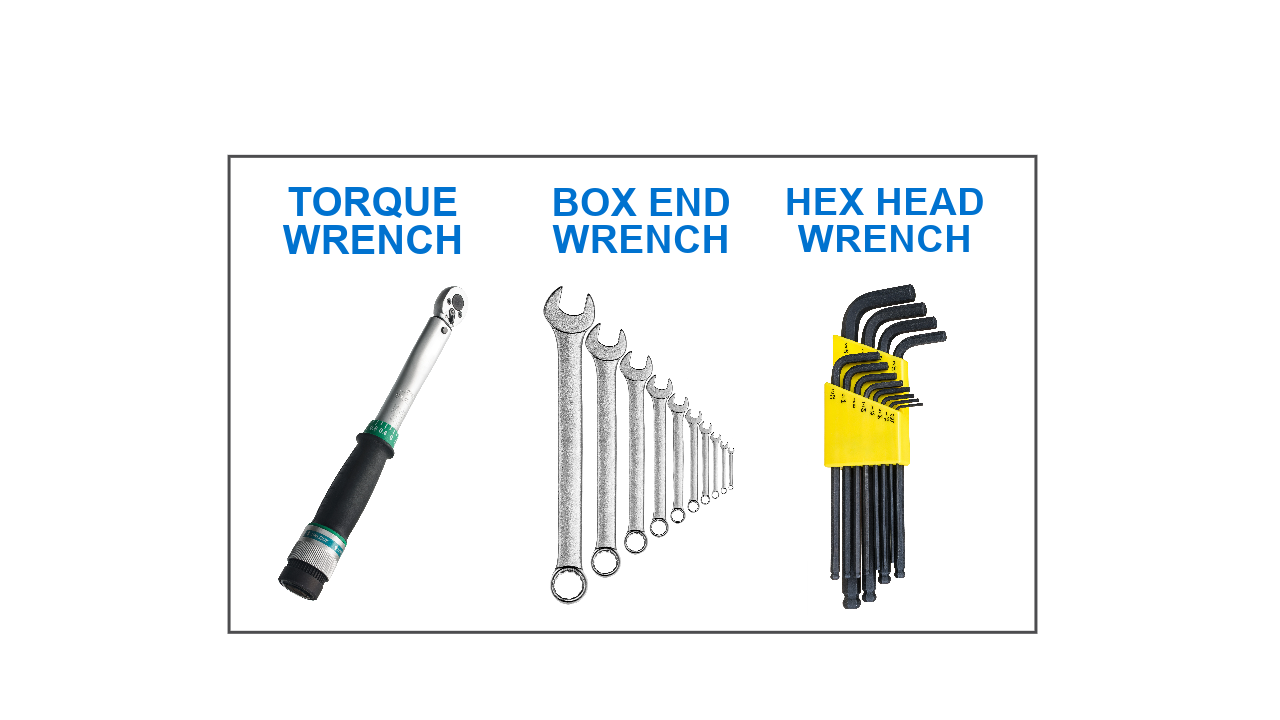

A reliable torque wrench is important for proper tension on fasteners to ensure long-term pump functioning. Whether a beam type, dial type, or digital model, the wrench should be of quality construction and calibrated regularly for accurate readings when tightening nuts and bolts. Be sure to use the correct size torque wrench for the application and always follow the manufacturer’s recommended torque settings.

Box end wrenches- again in both SAE and metric- make getting into those hard-to-reach places a little easier. Tight spaces where a socket wrench can’t be used like underneath the relief valve or in the seal area is what makes the box end wrench a key player in your pump repair toolkit.

The hex head wrench- or Allen wrench- are required for loosening or tightening the head set screws commonly found in seals and bearing housings on certain pump models.

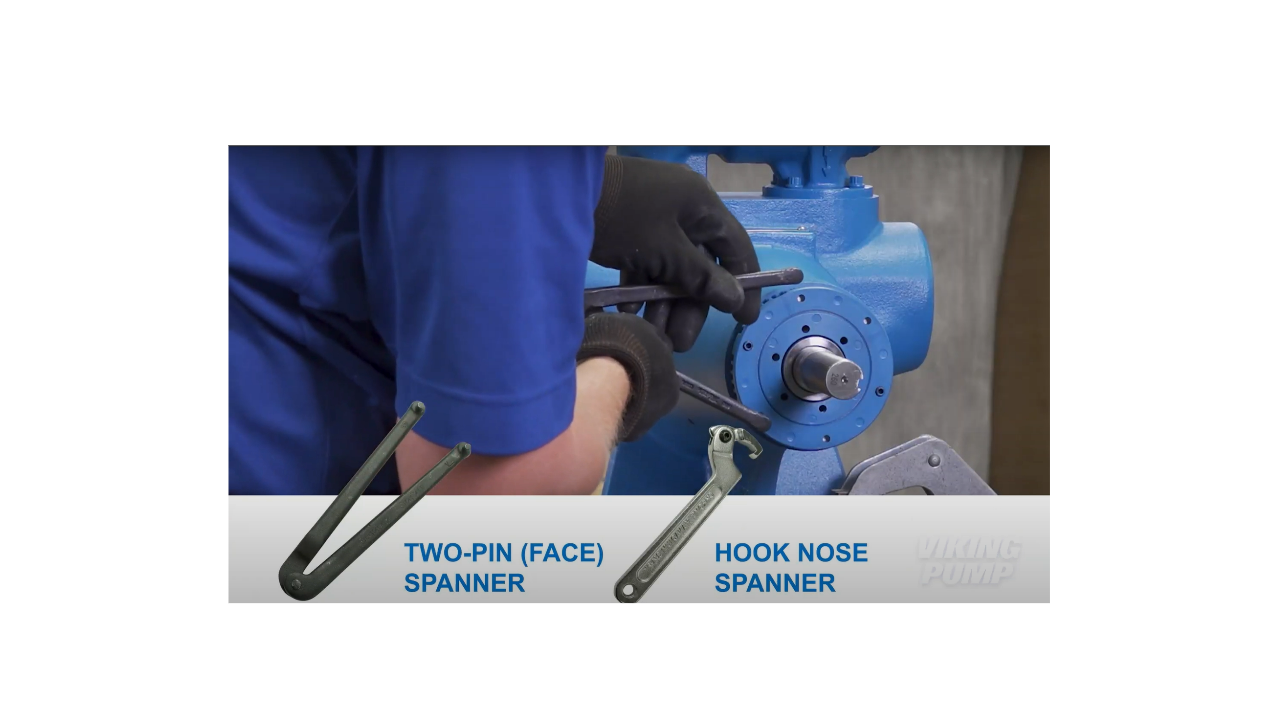

Last of the wrenches is the spanner wrench. These wrenches come in two variations: a two pin, or face spanner wrench has pins that can be inserted into corresponding holes on the face of the bearing housing of a pump in order to turn it to tighten or loosen. A hook nose spanner has an adjustable hook that can be used to grab the slot of slotted lock nuts. It can also be used to check the rotation of a pump by grabbing onto a shaft's keyway to rotate the shaft.

Because sometimes you need a little gentle persuasion. A rubber mallet is a great tool to aid with pump disassembly in a gentle way that won’t damage pump internals or externals. But it’s always wise to be cautious when hitting any part of the pump.

This next set of tools are slightly less common but should still be found in any repair shop working on pumps.

This tool is required for the installation or removal of snap rings. They come in two variations: external and internal. External snap ring pliers are required for snap rings on shafts. Internal snap ring pliers are required for snap rings in casing bores or bearing housings.

Pumps that use a packing seal require this specialized tool for seal maintenance. The miniature corkscrew at the end is the best way to extend your reach to grab hold of each packing ring to remove it from the stuffing box.

(Yes, we’re serious). This is a simple piece of material that is softer than the pump internals. When inserting into the pump, we can prevent the shaft from turning while preventing any damage to the pump internals.

Rotary positive displacement pumps feature very tight clearances. Feeler gauges allow for accurate measurement of these tight clearances inside the pump.

Finally, there are a few special tools that are required for only a few models of Viking pumps. Since these are special tools, these are provided with the respective repair or seal kits for these models.

- Tapered seal installation sleeve. Certain Viking Pump models have a step on the shaft. A tapered seal installation sleeve is required to help the seal get over the step and prevents any damage to elastomeric parts of the seal.

- Cross Socket. Viking hygienic lobe pumps feature a cross slot in the rotor retainer. A special cross socket is provided with seal kits to allow for removal or installation of these without damage.

- Slotted Wrench. For TRA®10 pumps, Viking Pump provides a special wrench. This wrench includes slots for removing the front cover wing nuts and the rotor retainer nuts.

And there you have it! Keep your toolbox stocked with these tools and you should be ready to roll with your next seal change or routine pump maintenance. And if you ever feel out of your depth, visit vikingpump.com/contact to get in touch with your area pump expert for repair & servicing options.

View the Pump Report that this blog post is based on below:

Need step-by-step instructions for the basics of pump repair? Visit our YouTube channel.