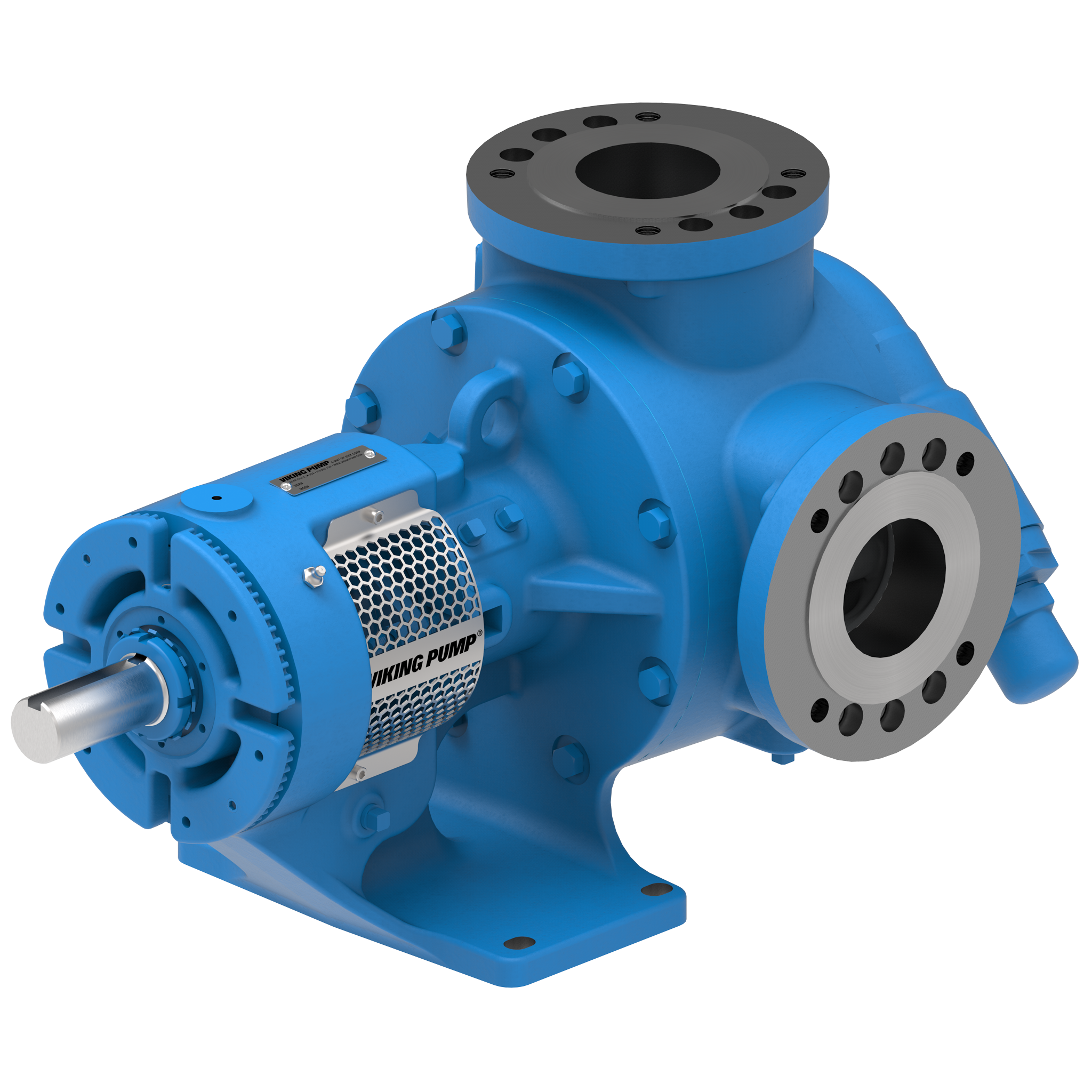

Experience flexible porting options, various seal solutions, and flow rates up to 320 gallons per minute.

This NEW pump design offers significantly more options to fit your current setup without compromising on Viking Pump’s reliable pumping principles that we have held since our founding in 1911.

And while you may be familiar with Viking products of the past, this next generation of pumps takes all the good parts and makes them even better.

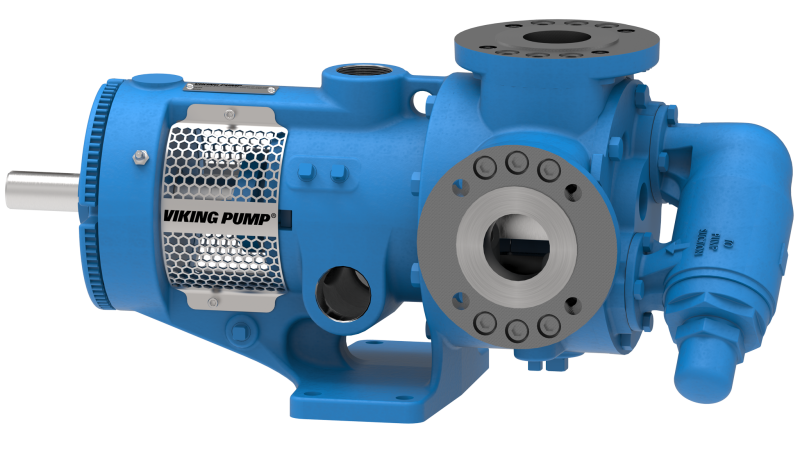

Viking Pump’s engineering team has made it simpler than ever to quickly connect your pump to the existing pipe setup.

The ProPort™ casing utilizes mounting pads on each port designed to fit a variety of different flange types and sizes, enabling flexibility when connecting pumps to piping.

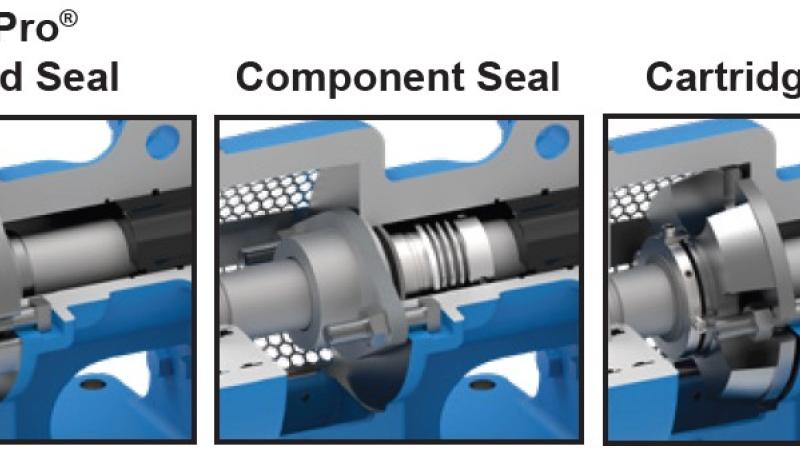

Changing seal types - which used to require massive updates and even purchasing a brand new pump – is now headache-free.

The U-Plus™ bracket offers seal location to be in the stuffing box OR behind the rotor, giving more flexibility to make changes down the line.

FEATURES & BENEFITS

- All stainless steel construction for corrosion resistance over a wider pH range

- ProPort™ casing utilizes mounting pads on each port designed to fit a variety of different flange types and sizes, enabling flexibility when connecting pumps to piping

- U-Plus™ bracket offers seal location to be in the stuffing box or behind the rotor

- Jacketing options: Integral jacketed chambers in bracket and head allow pumps to maintain constant temperature and consistent product flow

Heading

127C SERIES™

- Stainless Steel

- Packing

- up to 320 GPM

Heading

1127C SERIES™

- Stainless Steel

- O-Pro® Seal

- up to 320 GPM

Heading

4127C SERIES™

- Stainless Steel

- Mechanical Seal

- up to 320 GPM

Heading

227C SERIES™

- Stainless Steel

- Packing

- Jacketed

- up to 320 GPM

Heading

1227C SERIES™

- Stainless Steel

- O-Pro® Seal

- Jacketed

- up to 320 GPM

Heading

4227C SERIES™

- Stainless Steel

- Mechanical Seal

- Jacketed

- up to 320 GPM

FEATURES & BENEFITS

- All steel construction for refinery and petrochemical applications

- Robust design is recommended for extremely high temperatures

- ProPort™ casing utilizes mounting pads on each port designed to fit a variety of different flange types and sizes, enabling flexibility when connecting pumps to piping

- U-Plus™ bracket offers seal location to be in the stuffing box or behind the rotor

- Jacketing options: Integral jacketed chambers in bracket and head allow pumps to maintain constant temperature and consistent product flow

Heading

123C SERIES™

- Stainless Steel

- Packing

- up to 500 GPM

Heading

4123C SERIES™

- Steel

- Mechanical Seal

- up to 500 GPM

Heading

223C SERIES™

- Steel

- Packing

- Jacketed

- up to 500 GPM

Heading

4223C SERIES™

- Steel

- Mechanical Seal

- Jacketed

- up to 500 GPM

Viking Pump’s engineers took a look at customer challenges and made several upgrades that make the Next Generation Viking pump better than ever.

Heading

COMPLEX PIPING ARRANGEMENTS

- ProPort™ Casing offers adaptable port design with a variety of port sizes and types

- Swap out port sizes to meet your needs

- Rotatable casing

Heading

UNIVERSAL SEALING OPTIONS

- ONE U-Plus™ bracket seal chamber can accommodate Packing, Component Seal, Cartridge Seal, Behind the Rotor Seal, OR O-Pro® Guard Seal

Heading

THE PUMP THAT WORKS FOR YOU

- A change in piping arrangement or seal requirements used to mean purchasing an entirely new pump

- Keep your pump and simply swap out ports and seals for an adaptable solution that saves you time, money, and hassle

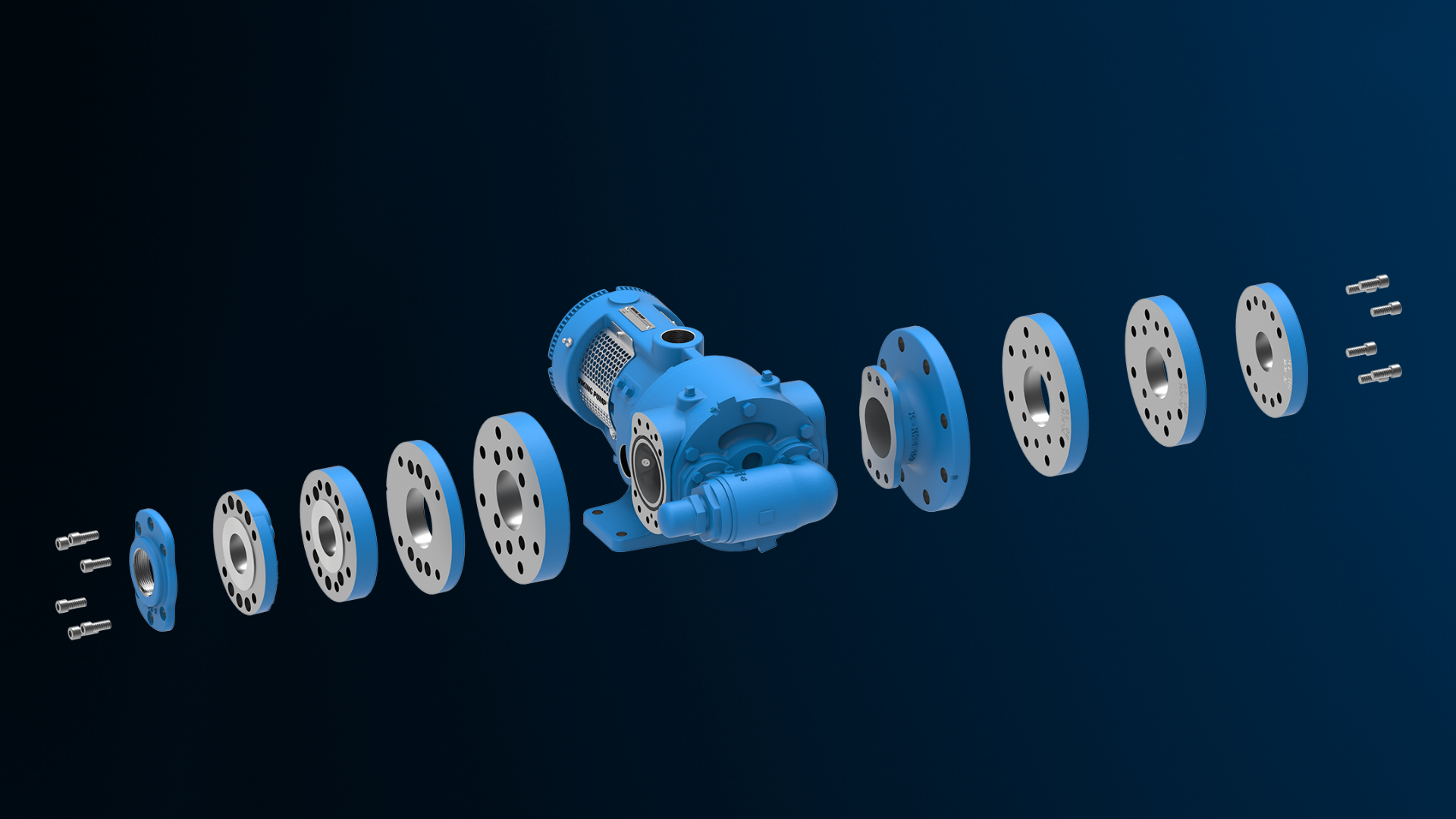

Once you own your next generation Viking pump, keeping up with maintenance or changes within the facility are no problem. Keep the core pump the same while having replacement flange faces, ports, seals, and casings so that the pump can evolve with you.

Heading

CHANGE THE PORT, NOT THE PUMP

Re-piping doesn’t mean you have to purchase a brand new pump and take the time to install it. Simply take a look at the replacement ports you have on the shelf or check with your area distributor.

Heading

CHANGE THE SEAL, NOT THE PUMP

If you determine that going from a behind the rotor seal to a cartridge seal is the way to go, simply reach for a spare cartridge seal on your shelf and replace it.

Heading

CHANGE THE CASING, NOT THE PUMP

Are you looking at an efficient piping change that means a 180° casing no longer fits best with the setup? Reduce the work it would take to install a brand new 90° oriented pump and swap out the casing instead.

This is just a small-scale example of what ONE pump can do. When you use Viking Pump’s new generation of stainless steel pumps, keeping spare ports, flange faces, and seals in your inventory means being able to do maintenance and updates across ALL of the Viking pumps at your facility.

REFERENCES

Introducing Viking Pump’s NEW Generation of Pumps

As a masterclass in engineering design and manufacturing flexibility, Viking Pump has re-designed its heavy-duty alloy pumps, both steel and stainless steel, in the most ingenious ways. These new models reduce price and lead time by significantly reducing the number of casings and brackets for manufacturing simplification, while simultaneously providing more options for porting and shaft sealing, all while adding many great new standard features.

All You Need to Know About ProPort™ Casings

Viking Pump’s new generation of internal gear pumps offer a wide array of benefits that the previous alloy pumps could not, particularly in the area of porting flexibility. These new pumps reduced the number of casing configurations, which helps reduce manufacturing complexity, cost and lead times, while at the same time increasing the number of porting options and providing greater porting flexibility.

Expanded Seal Flexibility with U-Plus™ Brackets

Viking Pump’s new generation of pumps (sizes H-QS in steel and stainless steel) offer a wide array of benefits that the previous alloy pumps could not, particularly in the area of sealing flexibility. These new pumps increase the number of sealing options possible in one pump, while at the same time reducing cost and lead times.

Viking Pump Industrial Tests New Modular Design at Stepan Company’s UK Facility

A loyal customer of Viking Pump® for 15 years, Stepan agreed to beta-test one of the latest pumps from our new Universal Product Line (4227C Series™) at their UK chemical manufacturing plant. Michael Smith Engineers is the local Viking Pump distributor, who initially approached Stepan as a likely pilot candidate due to a longstanding supplier-buyer relationship. Together, they set up the trial to demonstrate how...

If the NEW Generation of Viking Pump sounds like the perfect fit in your facility, or if you have any follow-up questions, let Viking Pump know.

The Viking Pump team of experts is on stand-by to help you through the decision-making process and optimize your facility. They understand downtime is painful and want to equip you with everything you need to reduce downtime AND alleviate installation headaches.

We look forward to hearing from you!

With over 110 years of experience providing positive displacement pumping solutions, Viking Pump has a rich, lengthy history of providing engineered solutions for tough applications. We have dedicated sales and field support specialists who are supported by a team of customer service representatives and engineers. Our knowledgeable team of application engineers available to help with product selection and technical support. Viking Pump is a USA based company with vertically integrated manufacturing facility.

- GLOBAL SALES AND SERVICE. Viking pumps are in operation on all 7 continents. Our worldwide network of factor-trained distributors understand your application and service needs.

- QUALITY MANUFACTURING. Our vertically integrated production process, from raw materials to finished product, meet ISO 9001:2015 quality standards. Global manufacturing footprint in the Americas, Europe, and Asia use Six-Sigma and Lean Kaizen tools.

- RELIABILITY, QUALITY & PERFORMANCE. Offering one of the broadest selections of pumping principles, designs, materials and options available, Viking pumps are time and field tested to meet or exceed your expectations.

- APPLICATION & INDUSTRY SUPPORT. Channel support group of application, sales and design engineers develops unique pumping solutions for both OEM manufacturers and pump end users with unique requirements.