Asphalt, also known as bitumen, is a sticky, black, and highly viscous liquid, or semi-solid form of petroleum. Asphalt is man's earliest organic engineering material. Its application as an adhesive and waterproof material dates to the dawn of civilization. The asphalt market thrives today largely for road building, roofing, and various types of repair work where its water-proofing qualities are required, as well as in rubber and adhesive compounds.

Asphalt cement is an asphalt that has been specially refined as to quality and consistency for direct use in the construction of asphalt pavement mixtures. This asphalt application must be heated to an appropriate high temperature to be fluid enough to be mixed and placed.

Emulsified asphalts are asphalt cement mixtures, a surfactant and water that is used in preparing base courses for pavement. It is also used in cold laid mixes, mix-in-place, and surface treatments. Asphalt emulsions must be perfectly homogeneous and able to withstand storage and shipping conditions. Most emulsions must not be subjected to climate conditions below 0°C, 32°F because freezing of the aqueous solution will coagulate the asphalt particles.

Emulsified asphalt is produced at both refineries where the asphalt is produced, and facilities solely built to produce emulsified asphalt. Pumps are used to deliver asphalt and the aqueous solution to the mixer or colloid mill.

Asphalt viscosity is graded according to temperature and setting speed (once placed on the road, after aging due to the heating and mixing process). The following are general uses of some common grades of asphalt:

· RS-1 Low viscosity for penetration and surface treatment.

· RS-2 High viscosity for surface treatment.

· MS-1 Low viscosity for re-tread mixes with coarse aggregate.

· MS-2 Medium viscosity for plant mixers with coarse aggregates.

· SS-1 For fine aggregate mixes.

For asphalt pumping we recommend that you take the following into consideration when selecting a positive displacement pump for asphalt cement applications:

- Steel fitted construction and extra clearances may be required, depending on the wide range of possible viscosities.

- Bronze bushings can be utilized for conditions up to 232°C (450°F). Carbon graphite is required for temperatures above 232°C. Note: High temperature graphite may be required depending on the pump size.

- Acceptable shaft seals include:

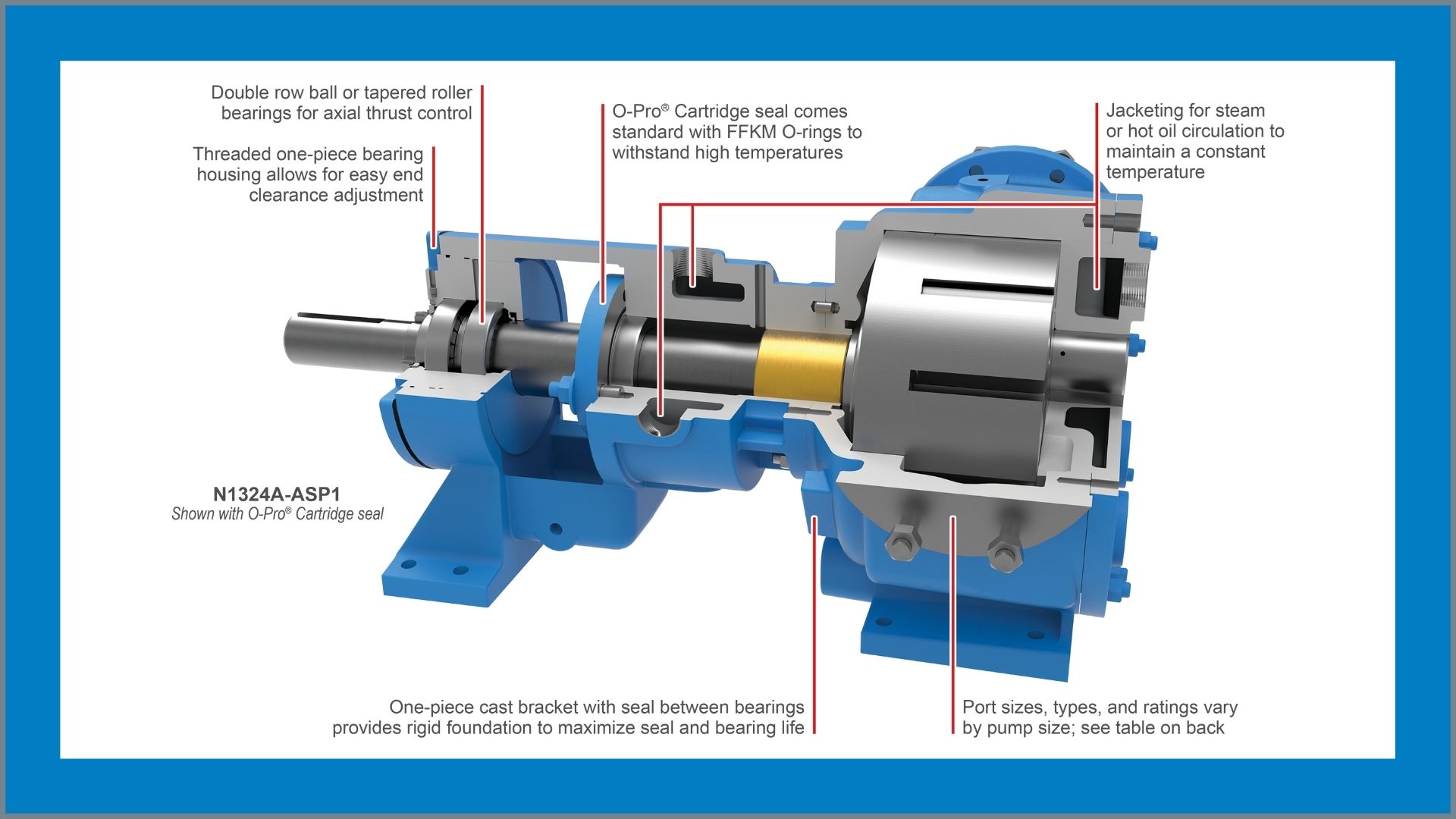

- Viking’s patented O-Pro® Cartridge seal with FFKM O-rings

- Packing

- Cartridge lip seal with quench

- Single metal bellows mechanical seal with hard faces and quench

- Double metal bellows mechanical seal with hard faces (inboard) and a pressurized barrier fluid

For help with selecting the right pump for your asphalt needs, contact a Viking Pump representative.