PUMP SOLUTIONS

Heading

INDUSTRIAL SOLUTIONS

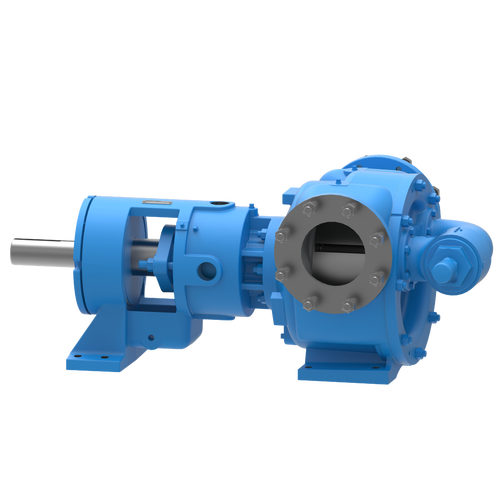

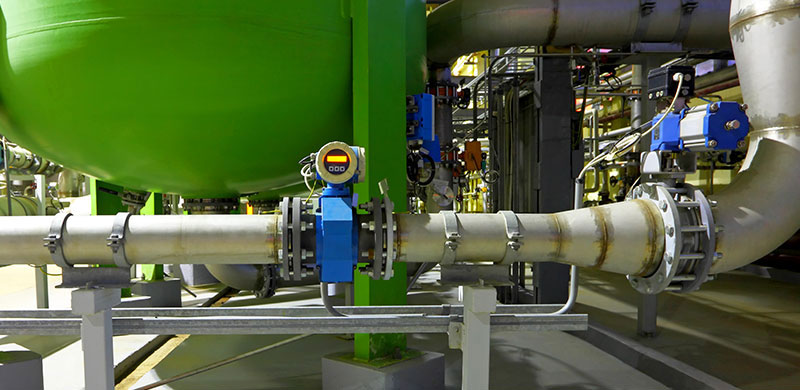

Viking Pump’s industrial gear pumps are the premiere positive displacement pump technology that covers nearly every pumping need.

Heading

ENERGY SOLUTIONS

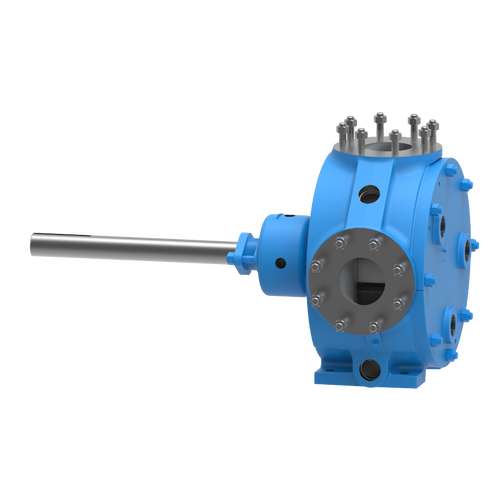

With construction options that have been proven to work for light, medium, and heavy-duty applications, the versatility and popularity of positive displacement pumps lie in their relatively simple design, high efficiency, and consistent flow rates.

Heading

HYGIENIC SOLUTIONS

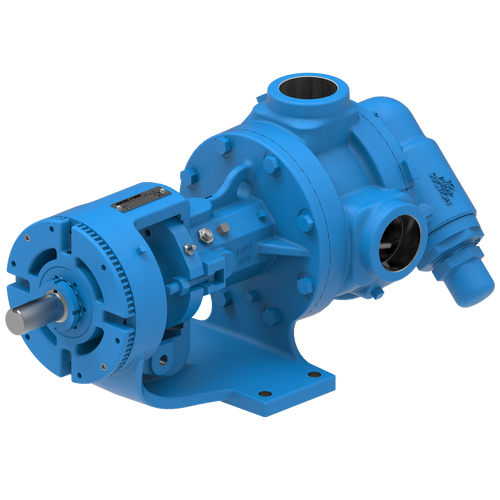

Viking Pump’s hygienic pumps offer the best efficiency and a wide range of porting, cleaning, and sealing options to meet your needs. In a business where cleanliness is key to reduce cross-contamination, we offer CIP (clean in place), SIP (sterilize in place), and COP (clean out of place) pumps to save you time and effort.

Heading

OTHER PUMPING SOLUTIONS

Viking Pump Canada offers a selection of Canada-specific products that cover a wide range of applications. From industrial to hygienic, there's a product offering to meet your needs.

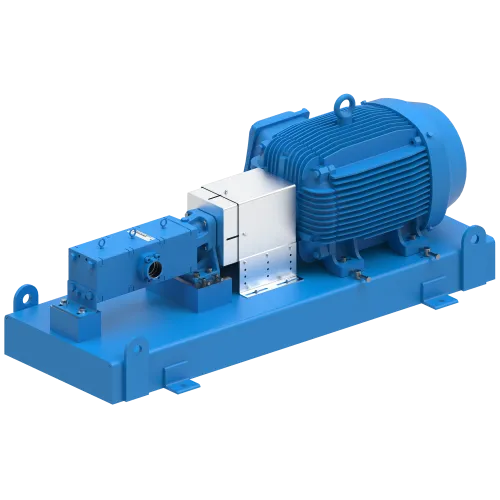

Custom Engineered Packages

Viking Pump Canada offers custom solutions based on your application.

- Engineered packages

- VFD's and controls

- Various drive options

- Seal flush plans

- Up to 200+ H.P.

- Industrial or hygienic applications

- API pump systems

Viking Pump of Canada offers competitive pricing and brings extensive experience in providing pump packages tailored to meet the unique requirements of large projects for our customers.

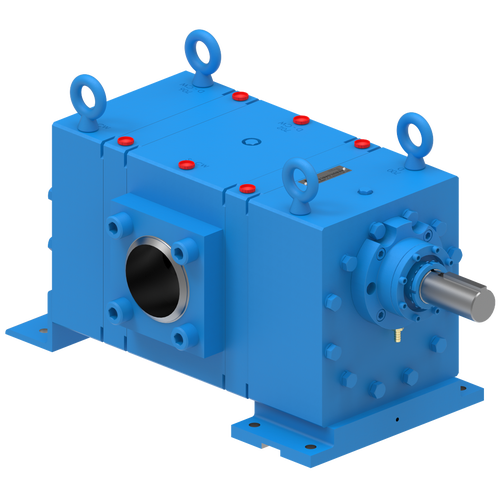

To ensure reliable pump performance, Viking internal and external gear pumps are combined with various gear reducer brands, operating at specific speeds and powered by multiple compatible motor brands. This combination not only enhances efficiency but also maximizes the longevity of the equipment. Our commitment to quality and customer satisfaction ensures that each pump package is optimally designed to deliver exceptional results in even the most demanding environments.

By leveraging advanced engineering techniques and rigorous testing protocols, we can provide solutions that meet the unique needs of each application, thereby fostering long-term partnerships with our customers. This collaborative approach allows us to adapt to changing market demands and technological advancements, keeping us at the forefront of the industry.

As we continue to innovate, our focus remains on delivering value and reliability, ensuring that our customers can trust in the performance of our products.

High Temperature Transfer Pump Assembly

• 450 (F) degree rated Asphalt application

• V-Belt driven assembly

• Jacketed casing and jacketed dual relief valve system

• Magnetic connectors

• Speed sensor

Food Grade Stainless Steel Pump Package

• Circumferential piston pump

• Peanut Butter/Caramel application

• High viscosity

• SS mobile push cart with casters

• Control panel and VFD

• Disconnect switch, cables, wiring

Artic Duty Low Temperature Package

• Flammable and toxic Emulsion application

• 200 HP motor

• Vibration detector sensors

• Various testing options

Technologies

Heading

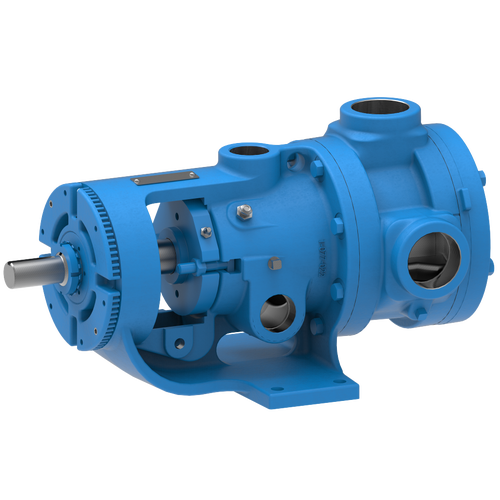

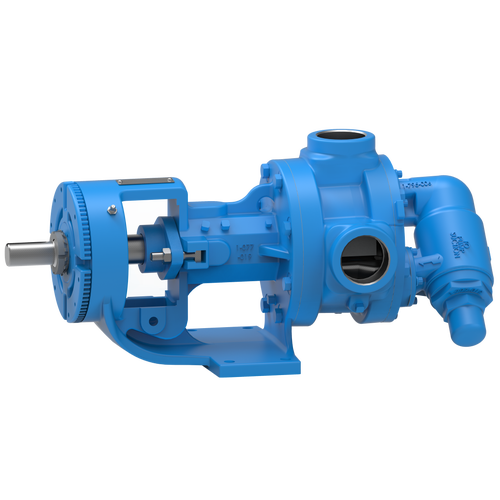

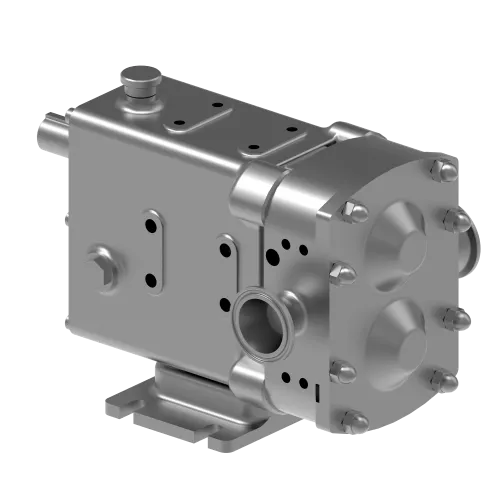

Internal Gear Pumps

Heading

External Gear Pumps

Heading

Circumferential Piston Pumps

Heading

Rotary Lobe Pumps

Heading

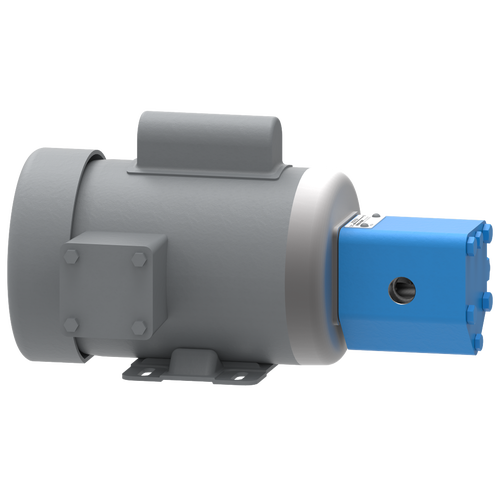

Vane Pumps

ISO 9001:2015 specifies requirements for a Quality Management System (QMS). To meet the requirements an organization demonstrates its ability supply product that meets customer and applicable statutory and regulatory requirements consistently. The organization must also strive to enhance customer satisfaction through the effective application of the QMS, including processes for continual system improvement and conformity assurance to customer and applicable statutory and regulatory requirements.

Asphalt Cement

Clean asphalt contains no fillers and is an oil based liquid. It is primarily used in paving roads, waterproofing liquids, and paints. Typically they are handled at elevated temperatures to reduce the viscosity of the asphalt. The pump needs a source of heat like jacketing or electric heat to prevent the product from solidifying in the pump.

- Cast iron

- Electric heating prior to pump startup

- Capacities to 1600 GPM

- Cast iron

- Jacketed for steal/oil heating prior to pump startup

- Lower pressures

- Capacities to 450 GPM

Resins

Resins are high viscosity liquids with potentially shear sensitive (thinning) components, and made up of solvents, waxes, surfactants, and semi-solid resin particles all with various chemical compatibility concerns. These resins can be used in polyurethanes, epoxies and other adhesives. In some cases, resins contain pigments that bring with them abrasive wear concerns.

- Cast iron

- Abrasive resistant sealing option

- Hardened iron bushings and hardened steel shaft

- Low shear

- Capacities to 400 GPM

- Cast iron

- Sealing options available

- Hardened materials standard

- Capacities to 180 GPM

- 316 stainless steel

- Sealing options available

- Hardened material options

- Capacities to 320 GPM

Crude Oils

This is a very generic term for unrefined oils typically being recovered from the ground. Some crude oil may contain particulates from the oil well or recovery method. They are considered to be flammable liquids. Crude oils are later refined and used for everything from making plastics to gasoline.

- Ductile iron

- Hardened, DLC coated parts for robust, long-lasting field performance

- Capacities to 210 GPM

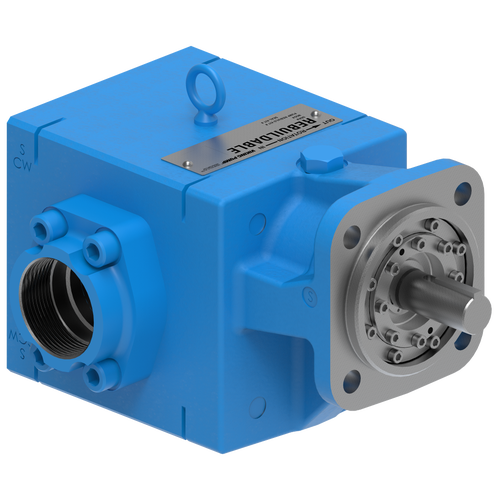

- Ductile Iron

- Enhanced wear resistance

- Rebuildable

- Capacities to 685 GPM

- Cast iron

- Abrasive resistant sealing options

- Hardened materials standard

- Capacities to 180 GPM

Chocolate

Cacao beans are roasted, ground up, and mixed with oils to get a semi-liquid which is the beginning point in the making of chocolate. Early stage chocolate is known as bitter chocolate. Add sugar and it is known as sweet chocolate. Add milk for milk chocolate. If the chocolate has been thinned down it is chocolate liquor. It can be diluted with fats like palm nut or coconut oils.

- Cast iron

- Jacketed for heating prior to startup

- Leak prevention with O-Pro® Barrier seal

- Capacities to 400 GPM

- Stainless Steel Externals

- Jacketed for heating prior to startup

- Leak prevention with O-Pro® Barrier seal

- Capacities to 320 GPM

Triethylene Glycol (TEG) for Gas Dehydration

Triethylene Glycol is used as a liquid desiccant to remove the water from natural gas. The hot glycol is injected into the gas pipeline at high pressures to dehydrate of the natural gas coming out of the ground.

- All sizes rated to 350°F and 1,500 psi

- Handle viscosities less than 1 cPs up to 550 cPs

- Hardened, DLC coated parts for robust, long-lasting field performance

- Ductile iron

- Hardened, DLC coated parts for robust, long-lasting field performance

- Capacities to 210 GPM

Polyol

Alcohols having many hydroxyl radicals are called polyols. Many companies market polyols under their own trade names. Product viscosity varies greatly depending on the specific polyol, but can be as thick as 40,000 cP. Polyols are often blended with isocyanates, so pumps handing polyols are often requested to be built using isocyanate compatible lubricants.

- Cast iron

- Cartridge lip seal sealing options

- Bushing options for compatibility

- Capacities to 500 GPM

- Cast iron

- Sealless design

- Bushing options for compatibility

- Capacities to 500 GPM

- Ductile Iron

- Sealless design

- Bearing option for compatibility

- Higher pressure capability

- Capacities to 190 GPM

Starch Adhesive

Starch based adhesives are used in the paper and corrugating industries. The raw starch is derived from a variety of plants such as corn, wheat, and potatoes. They tend to be shear sensitive (thickening) and are mixed in equipment commonly referred to as a starch kitchen.

- Cast Iron

- O-Pro® Barrier Seal to virtually eliminate leaking & mess associated with traditional packed pumps

- Pump and seal capable of withstanding upset pressures to 250 psi

- Abrasive resistant hardened features

- High strength hardened steel shaft

- Low shear

- Capacities to 200 GPM

LEADING THE WAY IN PUMP SERVICE FOR CANADA

Viking Pump Canada has the experience and product options to solve your fluid handling challenges. We can provide you with application specific products of rotary positive displacement and kinetic technologies including: Gear Pumps, Centrifugal Pumps, Vane Pumps, Lobe and Circumferential Piston Pumps, Diaphragm Pumps, Metering Pumps, Flow Meters, Systems and Controls.

Pump Choices in Chocolate and Confectionery Processing: Lobe/CP Pumps vs. Internal Gear Pumps

Compare Lobe/CP and Internal Gear Pumps for chocolate and confectionery processing. Learn which pump suits different applications based on hygiene, viscosity, and wear resistance.

Chocolate Plant Eliminates Leakage with O-Pro® Barrier

Discover how a major chocolate producer eliminated leakage and reduced maintenance costs using Viking Pump’s O-Pro® Barrier technology.

Viscosity Through Thick and Thin

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

U.S. EPA Bans Natural Gas-Driven Pumps

A new EPA rule (Dec 2, 2023) mandates zero-emissions pumps for oil & gas ops, replacing natural gas-driven pumps. It also limits other gas-powered equipment, curbs fugitive emissions, and reduces flaring of associated gas—with few exceptions.

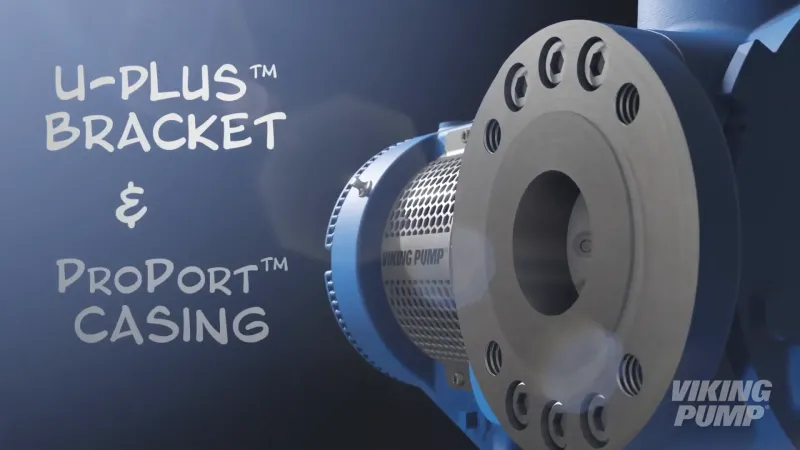

Introducing Viking Pump’s NEW Generation of Pumps

As a masterclass in engineering design and manufacturing flexibility, Viking Pump has re-designed its heavy-duty alloy pumps, both steel and stainless steel, in the most ingenious ways. These new models reduce price and lead time by significantly reducing the number of casings and brackets for manufacturing simplification, while simultaneously providing more options for porting and shaft sealing, all while adding many great new standard features.

Exploring the Versatility of the U-Plus™ Bracket and ProPort™ Casing in Gear Pumps

At Viking Pump, innovation is at the forefront of what we do. With the introduction of the U-Plus™ Bracket and ProPort™ Casing, we are redefining the capabilities of our internal gear pumps. These advancements are not just about new technology; they are about providing flexibility and efficiency in your pumping process. Let’s dive into what makes these innovations stand out.

ABOUT US

INNOVATIVE PUMPING SOLUTIONS FOR ANY APPLICATION

Viking Pump, a Unit of IDEX Corporation, leads the world in the design and manufacturing of rotary positive displacement pumps for use in some of the toughest applications. Since 1911, our innovative products have been key contributors to successful operations in virtually every industry- from military to food and beverage, to chemicals, fuels and plastics - reliably pumping materials that are thing, thick, hot, cold, liquid, solid, etc.