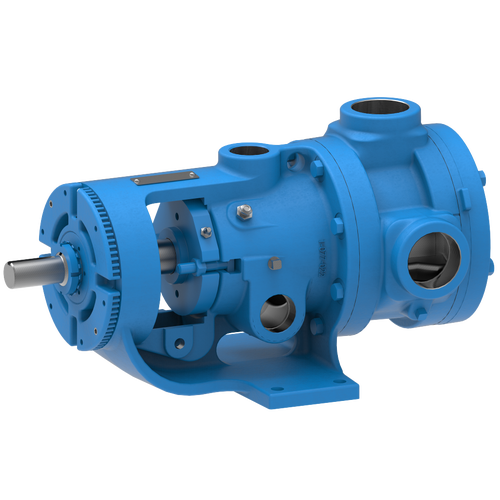

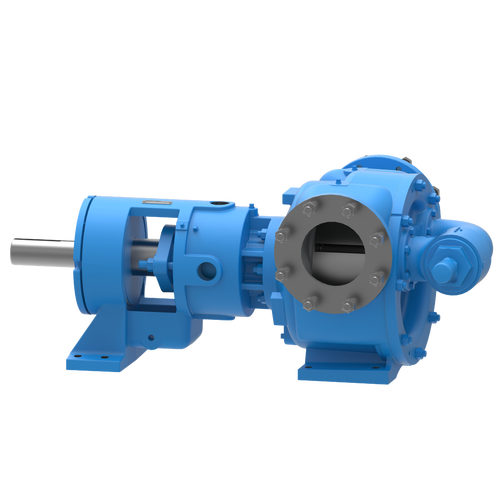

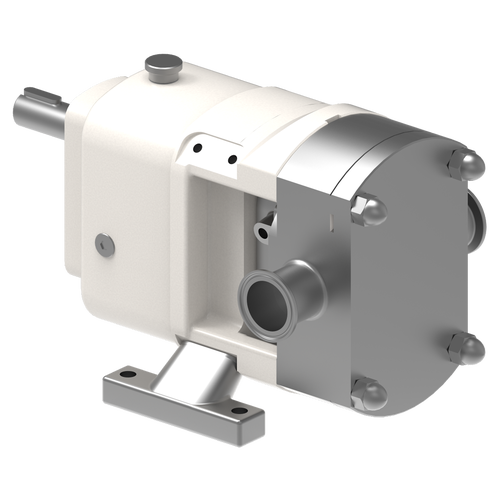

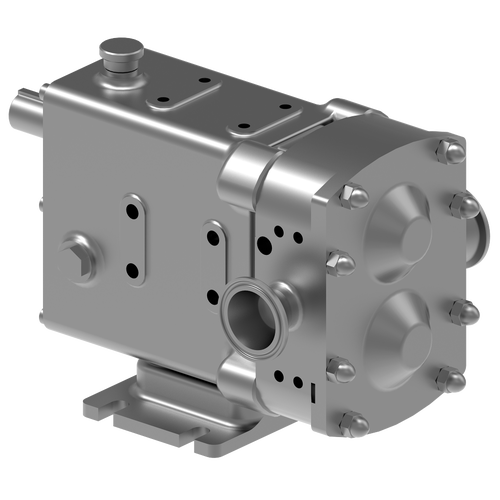

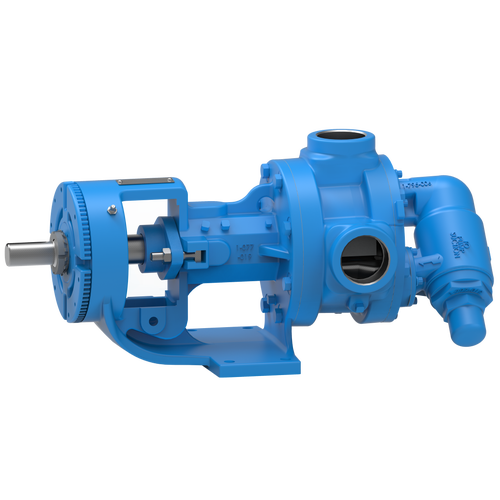

The RTP® Series rotary lobe pump was designed specifically for the hygienic stainless steel road tanker industry. It's the perfect solution for transferring high fructose corn syrup, chocolate, dairy, and more. The RTP® can handle flows up to 338 GPM (76.8 m³/h).

Features & Benefits

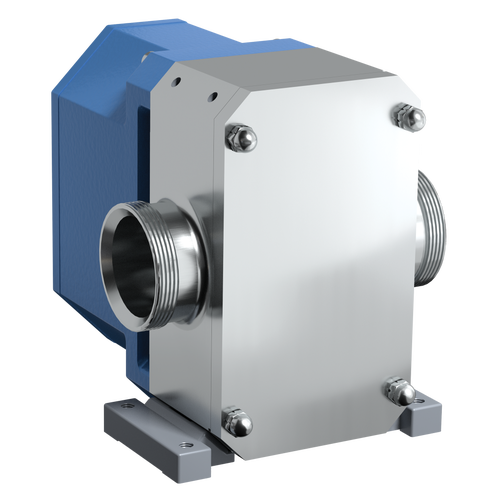

Cleanability

- The simple design behind the rotor makes strip cleaning easy and fast

- Choose the cleaning process that fits your needs: COP (Clean Out of Place) or CIP (Clean In Place)

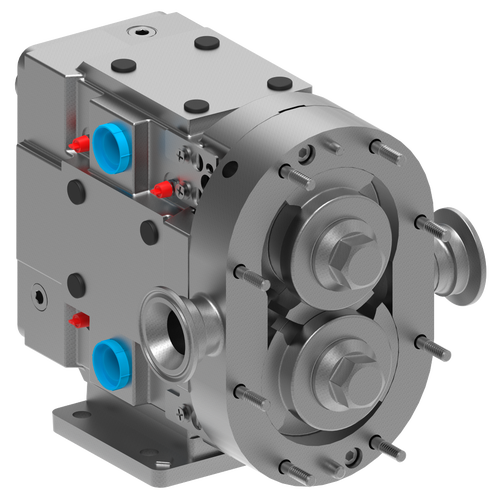

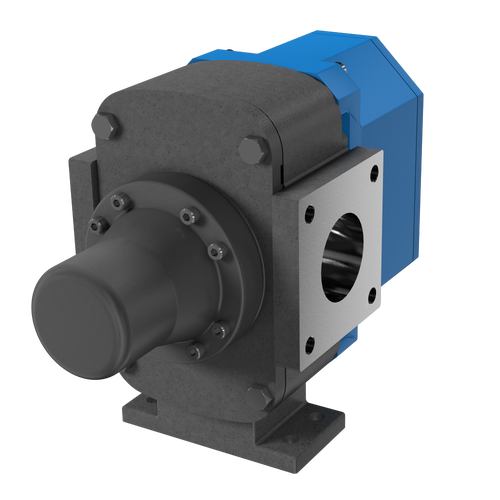

Ease of Maintenance

- Innovative front loading seal design enables quick inspection and easy servicing

- Sealed gearcase with long-life lubrication eliminates oil inspection and filling

- Easy to service design requires no special tools for disassembly and eliminates need for end clearance adjustments

Performance

- Easily handles higher viscosity liquids with improved pressure capabilities for faster unloading

- Excellent displacement/weight ratios, meaning more in the tank & less in the cabinet

- Precision helical gears, rotors & shaft design, with optimized bearing position, minimize overhung load – extending seal & bearing life

Capacity

0 to 338 GPM

0 to 76.8 m³/h

Viscosity

0 to 910,000 SSU

0 to 200,000 cSt

Pressure

0 to 174 PSI

0 to 12 Bar

Temperature

0 to 300 °F

0 to 150 °C

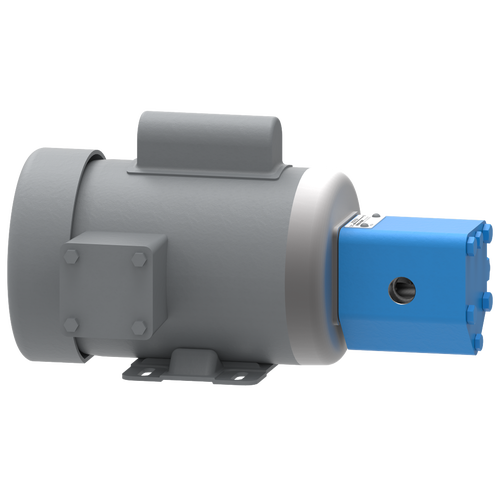

Options

Porting

Drives

Mounting

Sealing

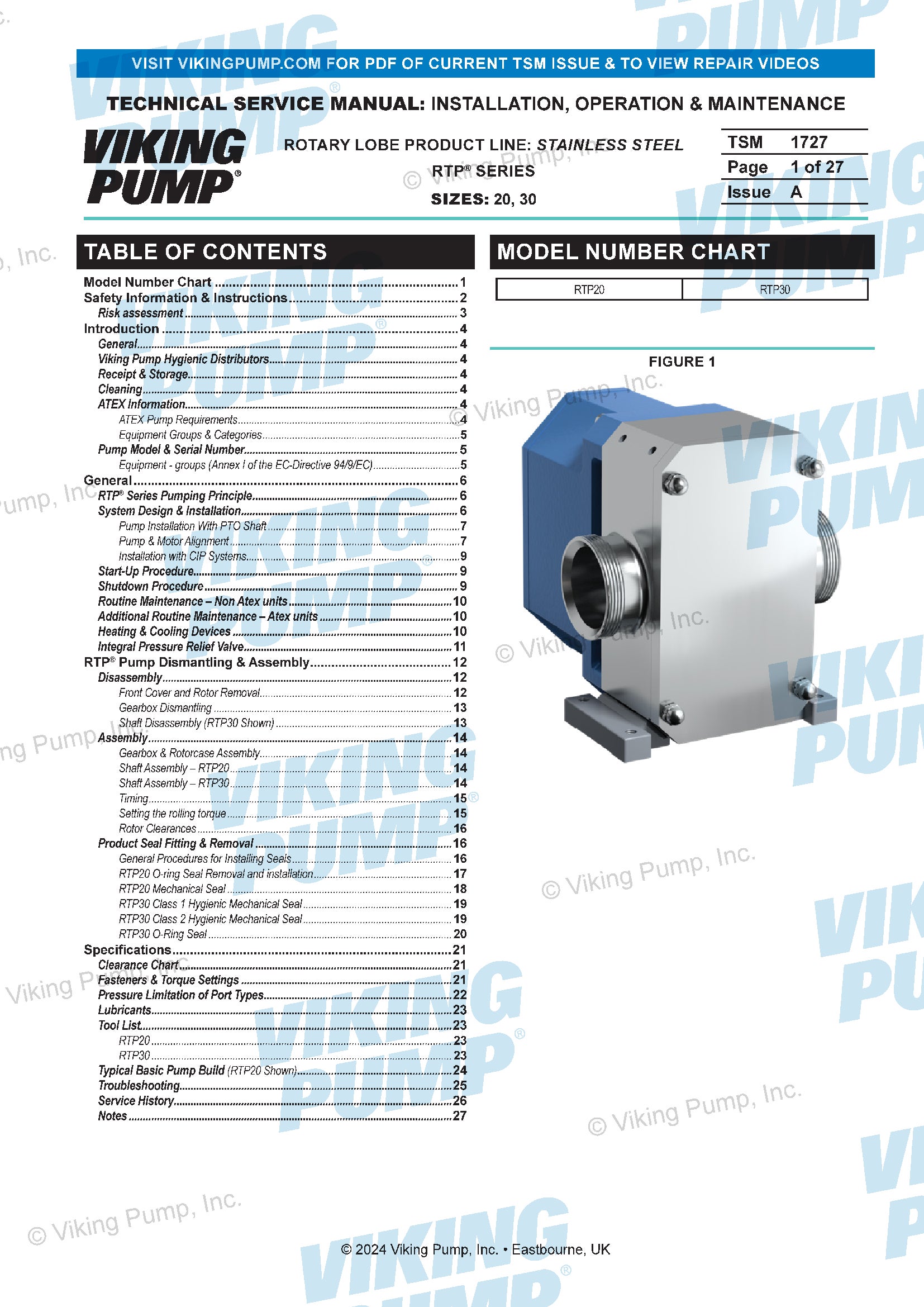

Specifications

| Model | Standard Port Size | Nominal Pump Rating (GPM) | Nominal Pump Rating (m3/h) | Maximum RPM | Maximum Pressure PSI | Maximum Pressure BAR |

|---|---|---|---|---|---|---|

| RTP20 | 2" or 3" | 264 | 60 | 1,000 | 145 | 10 |

| RTP30 | 3" or 4" | 338 | 76.8 | 1000 | 174 | 12 |

Videos

High Fructose Corn Syrup (HFCS)

High Fructose Corn Syrup (HFCS) is usually followed by the percentage of fructose in the liquid, ranging from 42 to 55%. It is most commonly used in soft drinks, jams, and jellies as a sweetener. Temperature regulation is relevant because discoloration of the liquid could occur at elevated temperatures.

Milk

Milk from cows, sheep, goats, and similar animals used as a food or beverage. The word now also used to describe liquids from plant sources such as coconut milk, soy or nut milks.

Cream (from Dairy)

Cream is a dairy product that is typically the fatty part of milk that rises to the top if allowed to stand. It is used in butter production and other food applications.

Edible Oils

This group of oils may consist of olive, palm, soybean, canola, pumpkin seed, corn, sunflower, safflower, peanut, grape seed, sesame, and rice bran or a blend of these oils that is typically referred to as vegetable oil.

-

REPAIR RESOURCES

RTP® Series | Single & Double O-ring Seal Replacement

-

DRAWINGS

RTP30 with Relief Valve - 3" Bevel/ACME/IAMD Top Shaft Drive PDF

STEP

RTP20 with Relief Valve - 3" Bevel/ACME/IAMD Top Shaft Drive PDF

STEP

RTP20 with Relief Valve - 3" ASA/ANSI Class 150 Top Shaft Drive PDF

STEP

RTP20 - 3" Bevel/ACME/IAMD Top Shaft Drive PDF

STEP

RTP30 - 3" Bevel/ACME/IAMD Top Shaft Drive PDF

STEP