Cream (from Dairy)

Hygienic positive displacement pumps are ideal for handling cream because they provide gentle and efficient transfer of viscous and shear-sensitive products. These pumps maintain a consistent flow rate, minimizing the risk of product degradation. They are designed to handle the delicate nature of cream without causing separation or damage to its structure. Additionally, these pumps are easy to clean and sanitize, making them suitable for food and dairy applications where hygiene is crucial.

Recommended Pumps

-

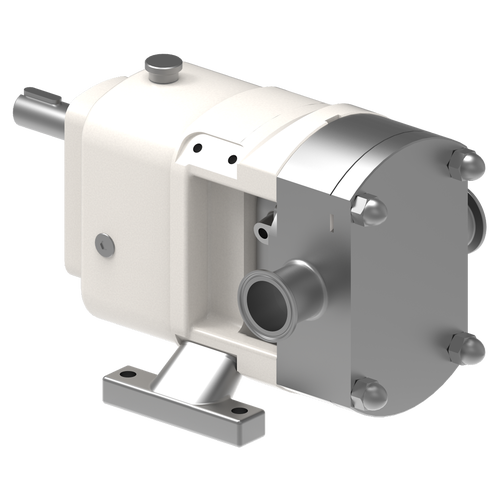

CLASSIC+ SERIES™

- Stainless Steel

- Mechanical Seal

- 0-832 gpm | 0-189 m3h

-

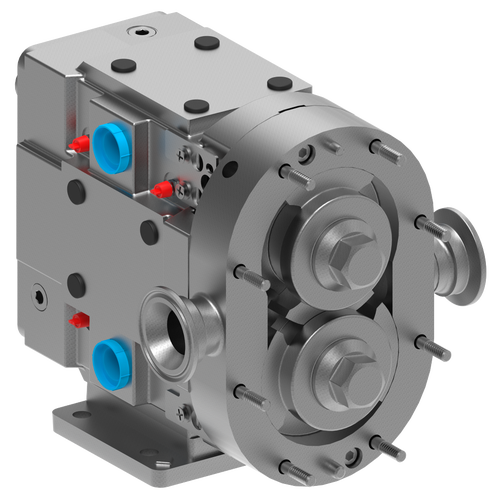

TRA®20 SERIES

- Stainless Steel

- Mechanical Seal

- 0-450 gpm | 0-102 m3h

-

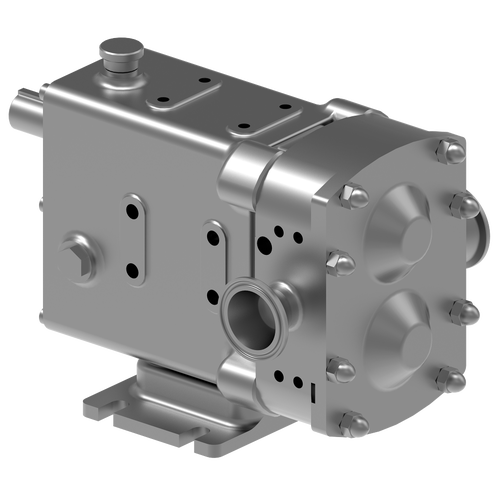

REVOLUTION® SERIES

- Stainless Steel

- Mechanical Seal

- 0-400 gpm | 1.8-91 m3h

Articles / Case Studies

There are really four main types of suppliers of hygienic, or sanitary pumps for food and pharmaceutical applications. There is no best source for everyone – each has advantages and disadvantages depending on your situation and budget. Here are some points to consider when choosing where to source your pumps.

Viking Pump invented the internal gear pump in the early 20th century; but did you know that we carry various other pump technologies? Most of them are easily identifiable based on their shape. But one common mistake… read more.

Videos

- Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

- Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025