We understand your challenge

- Once melted, many waxes are relatively low viscosity liquids. But viscosities can be higher for some specialty waxes.

- Complicated maintenance procedures require a pipeline shutdown in order to address issues. The downtime wastes valuable resources.

- Leaking product all over your pumps and floor can lead to costly cleanup and create a slip hazard to your workers.

Viking Pump has the solution

- Viking gear pumps can handle both high and low viscosity liquids, simplifying your processes.

- A rotatable bearing housing makes rotor end clearance adjustments easy.

- Our BXB Seres™ products come standard with our patented O-Pro® seal, virtually eliminating leaks and keeping your floors clean.

Heading

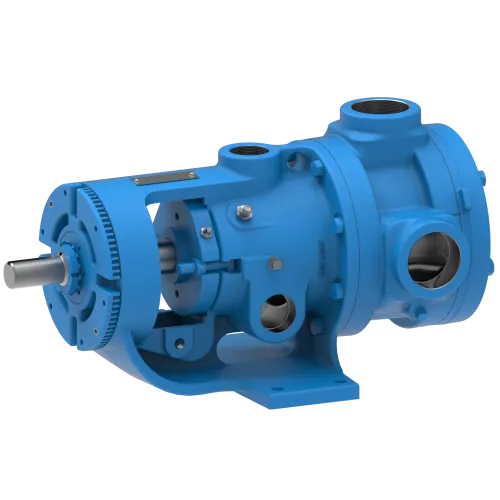

1224A-BXB SERIES™

- Cast Iron

- Jacketed for steam/oil heating prior to pump startup

- O-Pro® Barrier Seal to virtually eliminate leaking & mess associated with traditional packed pumps

- Capacities to 200 GPM

Heading

4224A SERIES™

- Cast Iron

- Jacketed for steam/oil heating prior to pump startup

- Mechanical seal options

- Capacities to 500 GPM

Heading

227C SERIES™

- 316 Stainless Steel

- Jacketed for steam/oil heating prior to pump startup

- U-Plus™ Bracket seal chamber that accepts a variety of seal types (packing, O-Pro® Guard, component, and more)

- ProPort™ Casing accommodates a variety of flange types and sizes

- Capacities to 320 GPM

Wax Applications

- Box coatings for food boxes

- Yogurt containers

- Produce boxes

- Juice boxes

- Wax coating for fresh produce

- Paper coating

- Candle manufacturing

Waxes can be natural secretions of plants or animals, such as beeswax, or by products of petroleum refining. Wax is commonly used in the paper and corrugated cardboard industries to make products such as cartons and paper packaging moisture resistant. Wax can also help prevent food products from sticking to paper packaging.

Viking in the Process

Once melted, many waxes are relatively low viscosity liquids, but viscosities can be higher for some specialty waxes. Viking pumps are used for manufacturing and refining oilseed waxes at oilseed processors, petroleum-based waxes at oil refineries, and bees wax at honey processors. They are also used to transfer molten wax in downstream product manufacturing applications such as box coatings. Viking pumps are used to transfer liquid wax from the melter to curtain coaters that feed box blanks under a curtain of liquid wax that coats one side of the blank and passes it to a drying section.

Cast iron construction is typically satisfactory, but stainless may be required for purity considerations. Depending on specific melting temperature, jacketed pumps are frequently required. Standard construction pumps with carbon bushings can generally be used, but some crude or filled waxes may require hardened constructions, such as tungsten carbide idler pin and bushing.

Replace Packing or Mechanical Seals with O-Pro®

Each O-Pro® Seal design option replaces packing or a mechanical seal by occupying the internal bracket cavity with a machined seal gland. Utilizing O-rings to seal externally on the bracket and internally on the shaft, a combination of O-rings and lubricating grease provide a robust seal. This prevents process fluids from leaking out of the pump.

With over 110 years of experience providing positive displacement pumping solutions, Viking Pump has a rich, lengthy history of providing engineered solutions for tough applications like corrugated cardboard. Our dedicated sales and field support specialists are supported by a team of customer service representatives and engineers plus a knowledgeable team of application engineers are available to help with product selection and technical support.

Viking Pump's commitment to innovation and performance has made us a leader in the industry. Our extensive product line offers an array of solutions for corrugated box manufacturers, from our high-performance pumps to our advanced engineering capabilities. With a variety of custom designs available, Viking Pump can help you optimize your production process and increase your bottom line.