Gelatin

Stainless steel hygienic gear pumps are ideal for transferring gelatin due to their exceptional corrosion resistance, durability, and ability to maintain rigorous hygiene standards. Gelatin, often used in the food, pharmaceutical, and cosmetic industries, requires a pump that can handle viscous materials while ensuring that there is no contamination. Stainless steel, known for its non-reactive properties, is perfect for preventing any undesirable reactions with gelatin, ensuring product purity and safety. Additionally, these gear pumps are designed to be easily disassembled and cleaned, minimizing downtime and meeting the stringent sanitary regulations that govern industries handling consumable products. Their robust construction allows for seamless operation even under demanding conditions, making them an indispensable tool for efficient and hygienic gelatin transfer.

Recommended Pumps

-

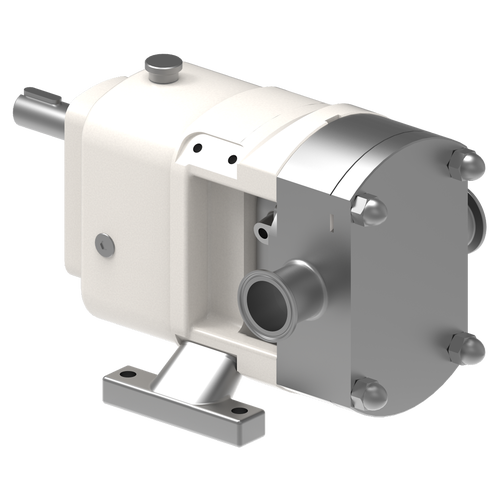

CLASSIC+ SERIES™ / MULTIPUMP® SERIES

- Stainless Steel

- Mechanical Seal

- 0-832 gpm | 0-189 m3h

-

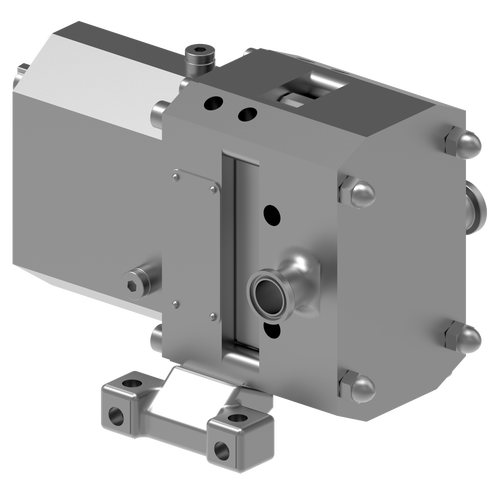

STERILOBE® SERIES

- Stainless Steel

- Mechanical Seal

- 0-753 gpm | 0-171 m3h

-

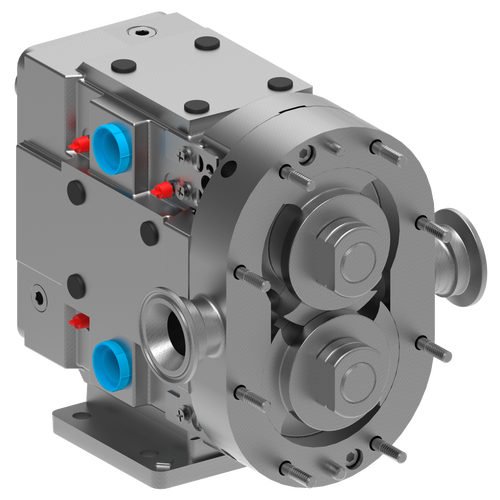

TRA®10 SERIES

- Stainless Steel

- Mechanical Seal

- 0-450 gpm | 0-102 m3h

- Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

- Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025