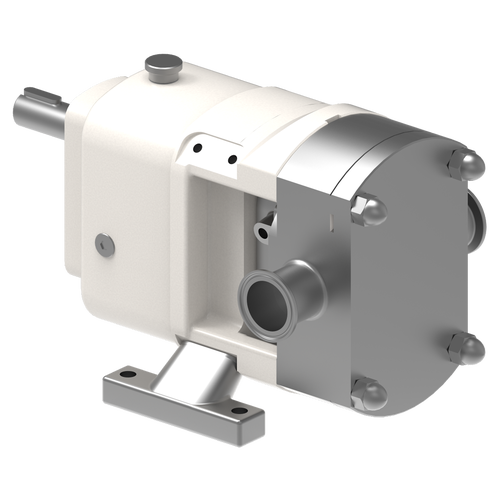

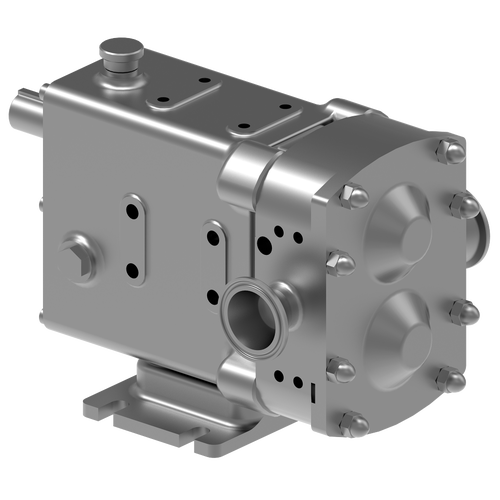

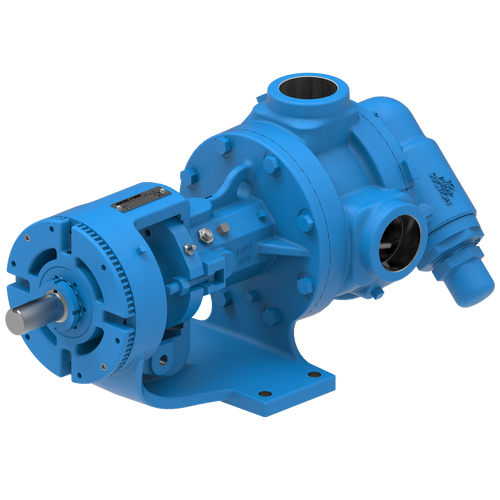

The TRA®10 Series hygienic pump is the ideal solution for dairy, bakery, meat processing, and more due to its cleanability and efficiency. It can handle flows up to 450 GPM (102 m³/h).

Features & Benefits

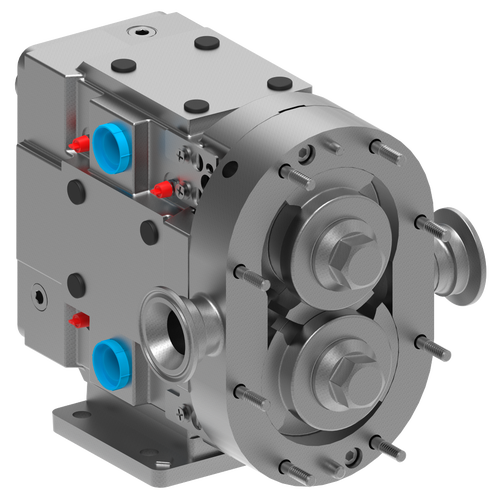

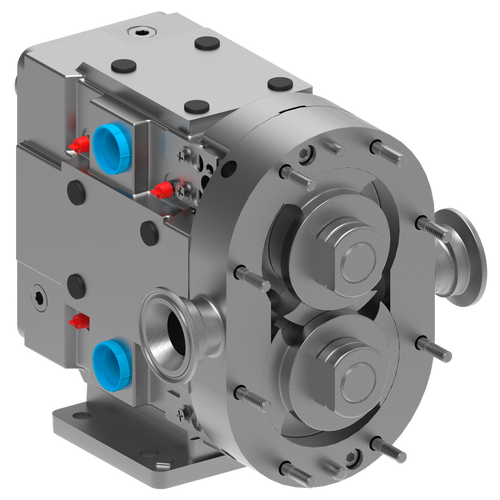

Cleanability

- Easy disassembly for easy COP (Clean Out of Place)

- Designed to 3A standards

Performance

- Efficient handling for low & high viscosity applications

- Exclusive, non-galling WFT 808® alloy rotors standard; permits running at tighter clearances

- High strength 17-4 PH single piece shaft standard on 0300 and larger

- Helical gears, improving load carrying capabilities

Ease of Maintenance

- Drop-in-place with TRA®20 & comparable manufacturer models

- Interchangeable service parts with comparable manufacturer models

- Easy disassembly

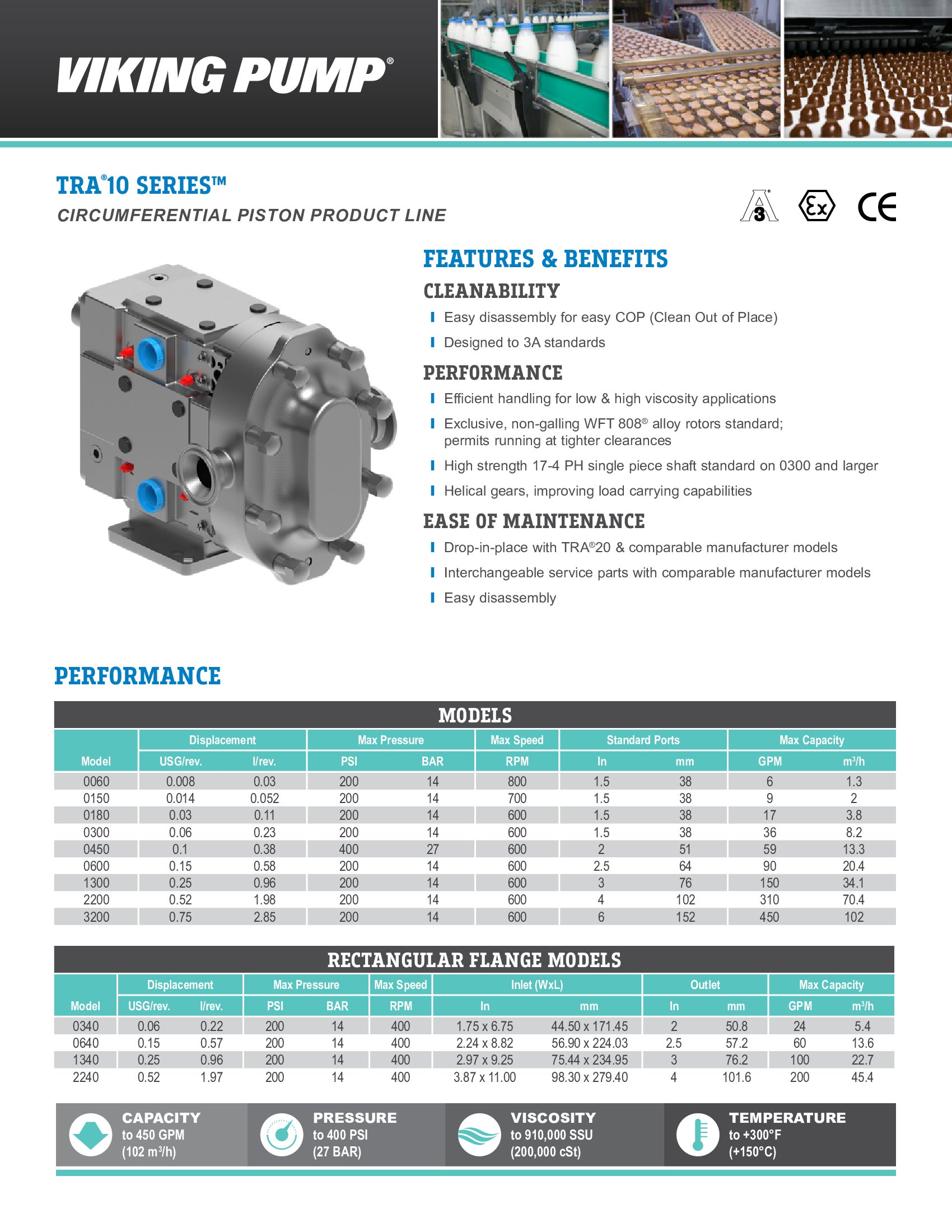

Capacity

0 to 450 GPM

0 to 102 m³/h

Viscosity

0 to 910,000 SSU

0 to 200,000 cSt

Pressure

0 to 400 PSI

0 to 27 Bar

Temperature

0 to 300 °F

0 to 150 °C

Options

Porting

Drives

Mounting

Sealing

Specifications

| Model | Standard Port Size | Nominal Pump Rating (GPM) | Nominal Pump Rating (m3/h) | Maximum RPM | Maximum Pressure PSI | Maximum Pressure BAR |

|---|---|---|---|---|---|---|

| 60 | 1.0" or 1.5" | 6 | 1.3 | 800 | 200 | 14 |

| 150 | 1.5" | 9 | 2 | 700 | 200 | 14 |

| 180 | 1.5" | 17 | 3.8 | 600 | 200 | 14 |

| 300 | 1.5" | 36 | 8.2 | 600 | 200 | 14 |

| 450 | 2" | 59 | 13.3 | 600 | 400 | 27 |

| 600 | 2.5" | 90 | 20.4 | 600 | 200 | 14 |

| 1300 | 3" | 150 | 34.1 | 600 | 200 | 14 |

| 2200 | 4" | 310 | 70.4 | 600 | 200 | 14 |

| 3200 | 6" | 450 | 102 | 600 | 200 | 14 |

Videos

Cream (from Dairy)

Cream is a dairy product that is typically the fatty part of milk that rises to the top if allowed to stand. It is used in butter production and other food applications.

Meat Products

Meat products typically used as foods cover a wide range of processed animal flesh and by-products.

Paints

Paints are shear sensitive liquids that can have a variety of solvents & pigment load concentrations that bring with them abrasive wear and chemical compatibility concerns.

-

REPAIR RESOURCES

TRA®10 Series | Double O-ring Seal Replacement Quick Tip #09 | Gearbox Shim Calculation Gearbox Rebuild | TRA®10 & TRA®20 Series TRA®10 Series | Disassembly TRA®10 Series | Single Mechanical Seal Replacement TRA®10 Series | Assembly TRA®10 Series | Single O-ring Seal Replacement

-

DRAWINGS

TRA10-0060-005 - 1" Tri-Clamp Horizontal PDF

TRA10-0060-009 - 1" DIN 11851 Jacketed Horizontal PDF

TRA10-0060-014 - 1.5" Tri-Clamp Horizontal PDF

TRA10-0060-015 - 1.5" Tri-Clamp Vertical PDF

TRA10-0060-017 - 1" Tri-Clamp Vertical PDF

TRA10-0060-018 - 1.5" DIN 11851 Horizontal PDF

TRA10-0060-022 - 1.5" Class 150 ANSI Horizontal PDF

STEP

TRA10-0060-023 - 1" SMS Vertical PDF

STEP

TRA10-0150-014 - 1.5" Tri-Clamp Horizontal PDF

TRA10-0150-018 - 1.5" Tri-Clamp Jacketed Horizontal PDF

TRA10-0150-019 - 1.5" Class 150 ANSI Horizontal PDF

STEP

TRA10-0150-020 - 1.5" Tri-Clamp Vertical PDF

TRA10-0150-025 - 1.5" SMS Horizontal PDF

STEP

TRA10-0180-015 - 1.5" DIN 11851 Horizontal PDF

TRA10-0180-016 - 1.5" DIN 11851 Vertical PDF

TRA10-0180-026 - 1.5" RJT Jacketed Horizontal PDF

STEP

TRA10-0180-028 - 2" Tri-Clamp Jacketed Horizontal PDF

TRA10-0180-029 - 1.5" Class 150 ANSI Horizontal PDF

STEP

TRA10-0180-030 - 1.5" Tri-Clamp Vertical PDF

TRA10-0180-031 - 1.5" Tri-Clamp Horizontal PDF

TRA10-0180-033 - 1.5" Tri-Clamp Jacketed Horizontal PDF

TRA10-0180-034 - 1.5" DIN 2633 Horizontal PDF

STEP

TRA10-0180-035 - 2" SMS Horizontal PDF

TRA10-0300-004 - 1.5" Tri-Clamp Horizontal PDF

TRA10-0300-005 - 1.5" Tri-Clamp Vertical PDF

TRA10-0300-013 - 1.5" DIN 11851 Vertical PDF

TRA10-0300-016 - 2" Tri-Clamp Horizontal PDF

TRA10-0300-018 - 2" DIN 11851 Horizontal PDF

STEP

TRA10-0300-020 - 2" Tri-Clamp Jacketed Horizontal PDF

TRA10-0300-021 - 1.5" DIN 11851 Jacketed Horizontal PDF

TRA10-0300-029 - 2" DIN 2633 Horizontal PDF

STEP

TRA10-0300-030 - 2" Class 150 ASA/ANSI Horizontal PDF

STEP

TRA10-0300-031 - 1.5" SMS Horizontal PDF

STEP

TRA10-0300-034 - 1.5" Class 150 ANSI RF Horizontal PDF

STEP

TRA10-0300-036 - 2" Tri-Clamp Vertical PDF

TRA10-0300-038 - 2" DIN 11851 Jacketed Vertical PDF

TRA10-0300-039 - 2" DIN 11851 Jacketed Horizontal PDF

TRA10-0300-040 - 1.5" Class 300 ANSI RF Horizontal PDF

STEP

TRA10-0340-002 - 1.5" Tri-Clamp Rectangular Inlet Vertical PDF

TRA10-0340-009 - 2" Tri-Clamp Rectangular Inlet Vertical PDF

TRA10-0340-010 - 1.5" Tri-Clamp Rectangular Inlet Horizontal PDF

TRA10-0340-011 - 2" DIN 11851 Rectangular Inlet Jacketed Vertical PDF

TRA10-0450-001 - 2" Tri-Clamp Horizontal PDF

TRA10-0450-002 - 2" Tri-Clamp Vertical PDF

TRA10-0450-009 - 2" Class 150 ANSI/ASA Horizontal PDF

STEP

TRA10-0450-018 - 2" NPT Horizontal PDF

STEP

TRA10-0600-001 - 2.5" Tri-Clamp Horizontal PDF

TRA10-0600-002 - 2.5" Tri-Clamp Vertical PDF

TRA10-0600-006 - 2.5" Class 150 ANSI RF Jacketed Horizontal PDF

STEP

TRA10-0600-013 - 3.0" Tri-Clamp Jacketed Horizontal PDF

TRA10-0600-015 - 2.5" DIN 11851 Horizontal PDF

TRA10-0600-020 - 3" SMS Horizontal PDF

STEP

TRA10-0600-025 - 2.5" Tri-Clamp Jacketed Horizontal PDF

TRA10-0600-027 - 3" SMS Vertical PDF

STEP

TRA10-0600-028 - 2.5" NPT Horizontal PDF

STEP

TRA10-0600-031 - 2.5" DIN 2633 Horizontal PDF

STEP

TRA10-0600-032 - 3" DIN 11851 Horizontal PDF

STEP

TRA10-0600-033 - 2.5" Class 150 ANSI RF Horizontal PDF

STEP

TRA10-0600-037 - 2.5" NPT Jacketed Horizontal PDF

STEP

TRA10-0600-040 - 3" DIN 11851 Vertical PDF

STEP

TRA10-0640-003 - 2.5" Tri-Clamp Rectangular Inlet Vertical PDF

TRA10-0640-004 - 2.5" DIN 11851 Rectangular Inlet Vertical PDF

TRA10-0640-010 - 3" DIN 11851 Rectangular Inlet Horizontal PDF

STEP

TRA10-0640-011 - 3" DIN 11851 Rectangular Inlet Horizontal PDF

STEP

TRA10-0640-012 PDF

STEP

TRA10-0640-013 PDF

TRA10-0640-014 PDF

STEP

TRA10-0640-015 PDF

STEP

TRA10-0640-016 PDF

STEP

TRA10-0640-017 PDF

TRA10-1300-001 PDF

TRA10-1300-002 PDF

TRA10-1300-007 PDF

STEP

Drawing | 1300 | Horizontal PDF

STEP

TRA10-1300-015 PDF

STEP

TRA10-1300-018 PDF

STEP

TRA10-1300-022 PDF

STEP

TRA10-1300-024 PDF

STEP

TRA10-1300-025 PDF

STEP

TRA10-1300-026 PDF

TRA10-1300-029 PDF

TRA10-1300-030 PDF

STEP

TRA10-1300-031 PDF

STEP

TRA10-1340-001 PDF

TRA10-1340-008 PDF

TRA10-1340-009 PDF

STEP

TRA10-1340-010 RevA PDF

TRA10-1340-012 PDF

TRA10-1340-013 PDF

STEP

TRA10-1340-015 PDF

STEP

TRA10-1340-016 PDF

STEP

TRA10-1340-017 PDF

STEP

TRA10-2200-007 PDF

TRA10-2200-011 PDF

TRA10-2200-013 PDF

STEP

TRA10-2200-017 PDF

TRA10-2200-018 PDF

TRA10-2200-019 PDF

STEP

TRA10-2200-021 PDF

STEP

TRA10-2200-022 PDF

TRA10-2200-023 PDF

STEP

TRA10-2240-006 PDF

TRA10-2240-009 PDF

STEP

TRA10-2240-010 PDF

TRA10-3200-002 PDF

STEP

TRA10-3200-004 PDF

STEP