Fruit

Fruit

Custom Content One

Stainless steel hygienic gear pumps are ideal for processing fruit due to their exceptional sanitary properties and durability. Stainless steel is inherently resistant to corrosion and can withstand the acidic nature of fruit, ensuring longevity and reducing the risk of contamination in food processing applications. These pumps are designed to meet stringent hygiene standards, often featuring smooth surfaces and crevice-free construction to minimize the risk of bacterial growth. Additionally, their ability to handle the viscous and sometimes abrasive nature of fruit purees and juices ensures efficient and gentle transfer without compromising the product's quality. The robustness and cleanliness of stainless steel hygienic gear pumps make them a reliable choice for the fruit processing industry, where maintaining high standards of hygiene and product integrity is paramount.

Recommended Pumps

-

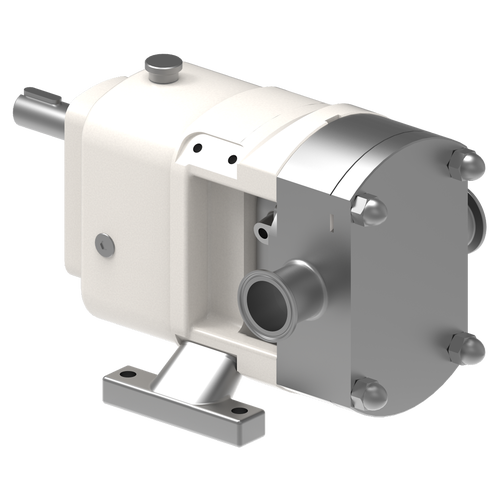

CLASSIC+ SERIES™

- Stainless Steel

- Mechanical Seal

- up to 832 gpm | up to 189 m3h

-

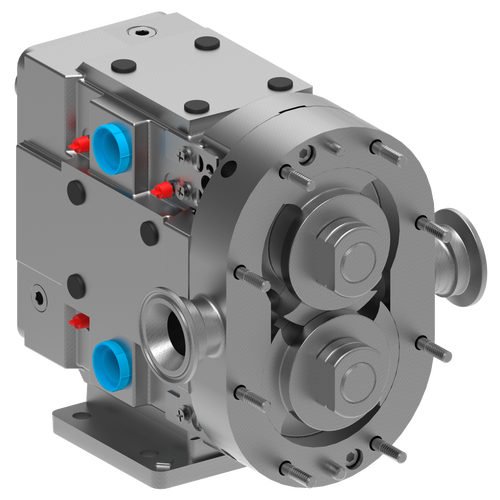

TRA®10 SERIES

- Stainless Steel

- Mechanical Seal

- up to 450 gpm | up to 102 m3h

-

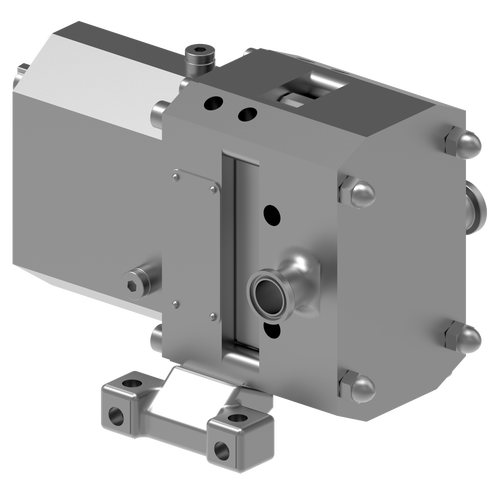

STERILOBE® SERIES

- Stainless Steel

- Mechanical Seal

- up to 753 gpm | up to 171 m3h

Articles / Case Studies

There are really four main types of suppliers of hygienic, or sanitary pumps for food and pharmaceutical applications. There is no best source for everyone – each has advantages and disadvantages depending on your situation and budget. Here are some points to consider when choosing where to source your pumps.

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

Videos

- Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

- Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025