Detergent Gel

Hygienic positive displacement pumps are ideal for transferring detergent gel due to their ability to handle high viscosity fluids with precision and care, maintaining the quality and consistency of the product. These pumps operate by trapping fixed amounts of gel and moving it through the pump in a controlled manner, minimizing the risk of shear and ensuring smooth flow without compromising the structure of the detergent. The meticulous design of hygienic positive displacement pumps also prevents contamination, making them suitable for industries where cleanliness and sanitation are paramount. Their robust construction and gentle handling make them perfect for managing the unique challenges posed by detergent gels, offering efficiency and reliability in various manufacturing processes.

Recommended Pumps

-

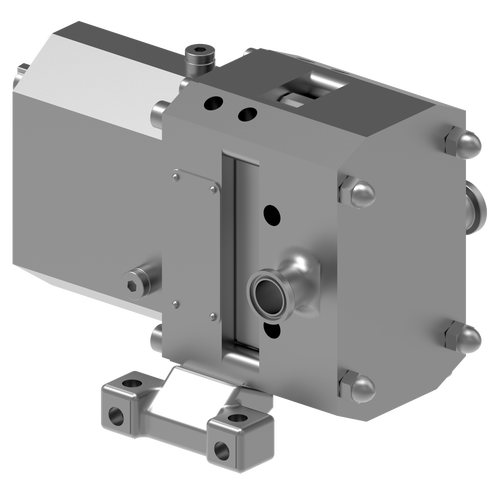

STERILOBE® SERIES

- Stainless Steel

- Mechanical Seal

- 0-753 gpm | 0-171 m3h

-

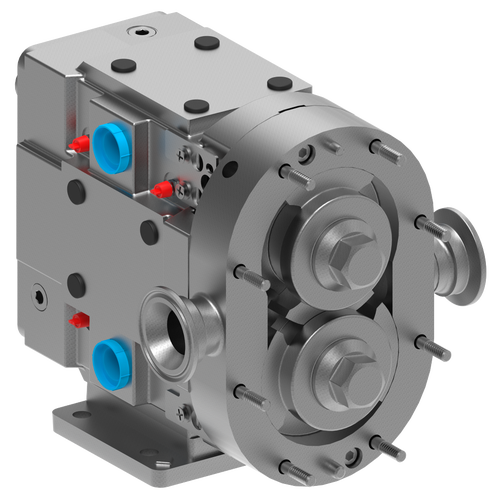

TRA®20 SERIES

- Stainless Steel

- Mechanical Seal

- 0-450 gpm | 0-102 m3h

-

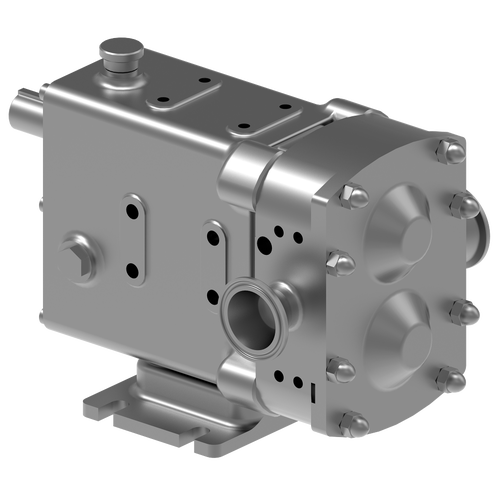

REVOLUTION® SERIES

- Stainless Steel

- Mechanical Seal

- 0-400 gpm | 1.8-91 m3h

- How Pump Packing Works - AnimationIn this video, learn about pump packing and how it works.March 14, 2025

- 50 States / 50 Pumping Applications: Connecticut, Florida, Illinois, Missouri, and WashingtonSince our founding in 1911, Viking Pump has built over 7,000,000 pumps and supplied them to customers all over the world. These pumps handle the broadest range of liquids in the industry. We’ve prepared a listing of 50 Viking pump applications, tying each to a state where this application can commonly be found. Today let’s explore Viking Pump applications in Connecticut, Florida, Illinois, Missouri, and Washington.February 28, 2025