The chocolate-making process is a delicate craft perfected over thousands of years. Cacao trees are harvested for their beans which are then roasted, ground up, and mixed with oils to create a semi-liquid, which is the beginning point in the making of finished chocolate.

If the chocolate has been liquified by heating, it is known as chocolate liquor (liquid chocolate).

Early-stage chocolate is called bitter chocolate named after it's bitter taste. Add sugar, and it is known as sweet chocolate. Add milk for milk chocolate.

Despite the name, white chocolate does not contain any chocolate liquor or cocoa solids. It is a mixture of cocoa butter, sugar, and milk. Chocolate can be further diluted with fats like palm oil, coconut oil, or lecithin.

CHOCOLATE MAKERS TRUST VIKING PUMP®

We Know the Struggle

- Slow and complicated pump startups

- Abrasive products wearing away at the pump internals

- Product buildup within the pump

- Leaky pumps leave product all over the floor leading to slip hazards and costly clean up

Positive displacement pumps have been the reliable solution to the challenges that the chocolate industry faces.

Heading

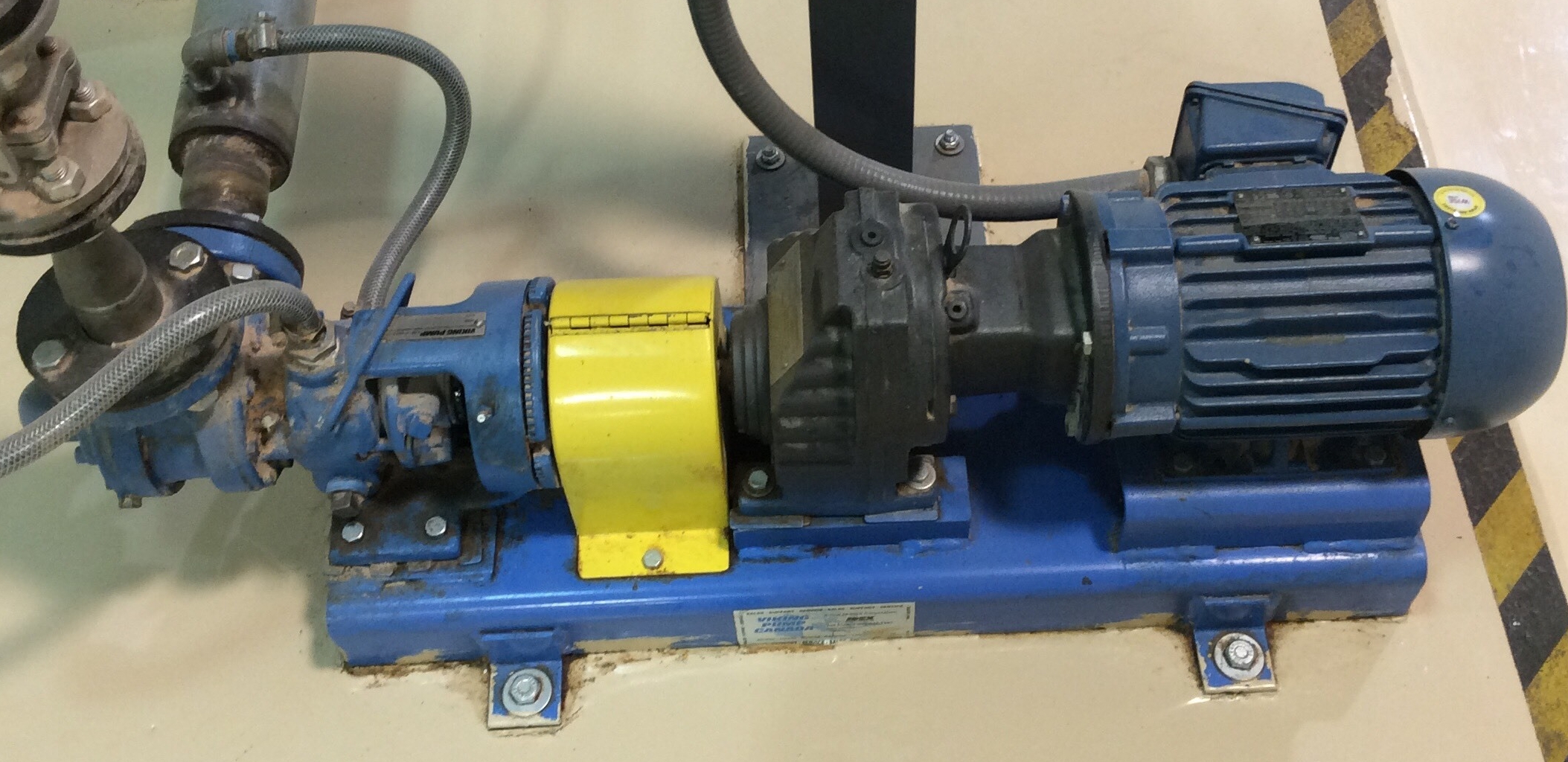

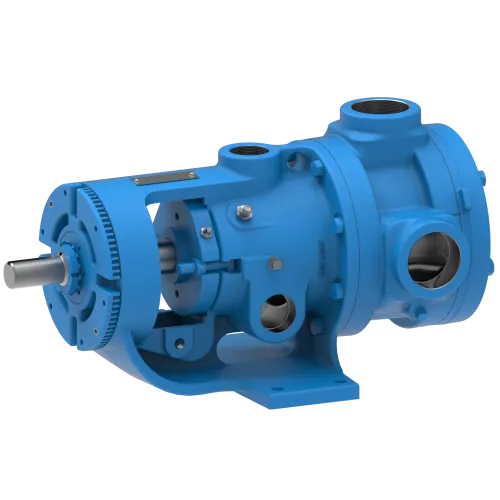

1224A-CHC SERIES™

- Leak Prevention with O-Pro® Barrier seal

- Reliability built to prevent solids buildup that prevents seizing

- Food Safety- EC1935 Compliant

- Simple Maintenance

Heading

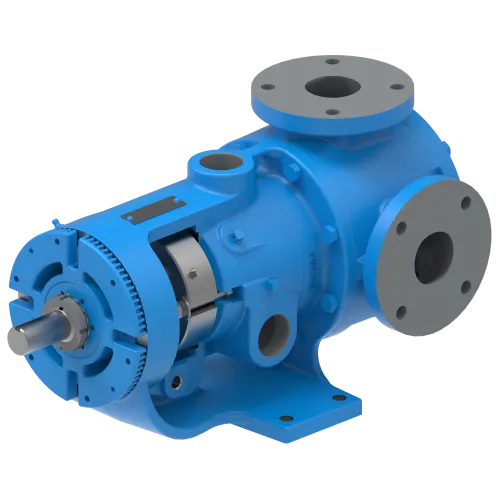

1227A-CHC SERIES™

- 316 stainless steel construction

- O-Pro® Barrier provides a robust sealing solution for many markets

- Integral jacketed chambers in bracket and head allow pumps to maintain constant temperature and consistent product flow

VIKING IN THE PROCESS

Viking pumps are used in the manufacturing process (bean to bulk), making confections (bulk to bar), and plants that do both (bean to bar). Whether it's loading or unloading tanker trucks, transferring materials from one process to another, or recirculating dark chocolate, milk chocolate, or white chocolate in an enrobing machine, Viking does it all. Typical applications for our product are shown on the process map and include transferring product between the following processes:

- Ingredient loading / unloading

- Transfer between storage tanks

- Tempering process

- Enrobing

- Depositing

- Cocoa mass milling

O-Pro® Seal vs Packing

We have listened to customers and evolved our offering to provide a seal that reduces loss of product due to leakage. A pump with packing allows for leakage, creating a slippery hazard in facilities. This makes the O-Pro® seal an excellent choice to add to your existing system.

Speak to an Expert

Our team of experts is ready to help you with your chocolate pumping challenges.

Viking has worked closely with processors to overcome the many difficulties of pumping chocolate and developed solutions for each unique chocolate liquid.

- Hardened parts to minimize wear by abrasive cocoa liquor

- Extra clearances and drilled idler gears to prevent caramelization of white chocolate

- Grooves to promote flow behind the rotor to prevent solids buildup on sugar-free chocolate

- Special seals for cocoa butter and fats

- Jacketed for smoother startups

- Cast iron and stainless steel material options

How can we help YOU?

With over 110 years of experience providing positive displacement pumping solutions, Viking Pump has a rich, lengthy history of providing engineered solutions for tough applications. We have dedicated sales and field support specialists who are supported by a team of customer service representatives and engineers. Our knowledgeable team of application engineers available to help with product selection and technical support. USA based company with vertically integrated manufacturing facility.

ALL PUMPS FACTORY TESTED

Our state-of-the-art testing equipment is used to confirm performance prior to shipments. Our world-class lab gives Viking Pump the ability to test our pump designs across a range of relevant variables.

TEST LAB

Our world-class lab gives Viking the ability to test its glycol pump designs across a range of relevant variables.

RELATED ARTICLES AND VIDEOS

Chocolate Plant Eliminates Leakage with O-Pro® Barrier

A major producer of chocolate confections in the eastern United States had been operating many Viking pumps on a variety of confectionary liquids for decades.

Many of these gear pumps have shaft packing, an extremely reliable means of preventing leaks, but which require some level of “controlled leakage” to cool and lubricate the packing. In a time of stricter FDA standards, food processors are now seeking new solutions to eliminate leakage, as it can create a slip and fall hazard and, furthermore, waste valuable product.

Distributor Spotlight | Rogers Machinery

Rogers Machinery Company, Inc. was co-founded in 1949 by two war buddies, Ned Rogers and Walter M. Novak, who served together aboard the USS Reno in the South Pacific during WWII. These like-minded veterans followed their dream to build a business providing compressed air equipment and pumps to the Pacific Northwest (Portland, Oregon), home to the pulp and paper, aluminum, agriculture, and food processing industries. Since they were far away from key suppliers on the East Coast, the company did their own customized packaging of products from Day 1; and to fill the long-distance gap, they also found it necessary to maintain a significant local inventory level and develop close customer ties.