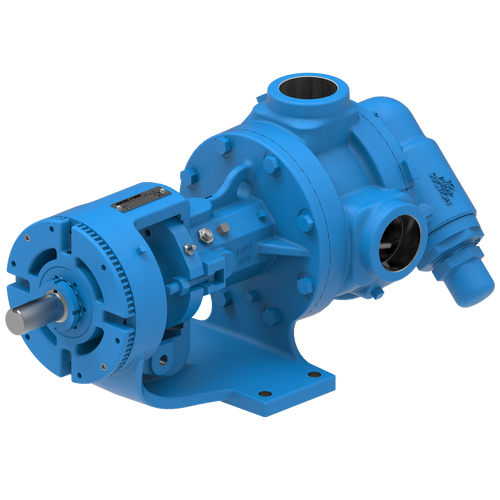

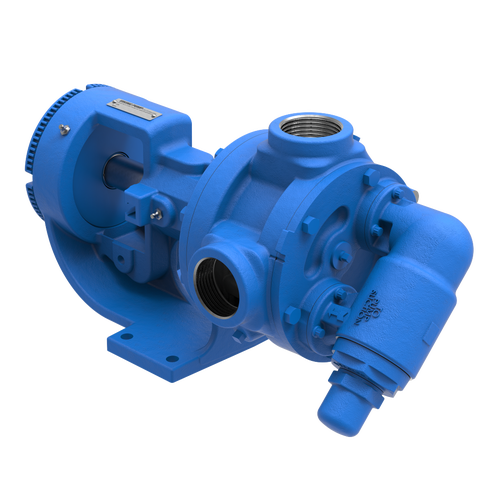

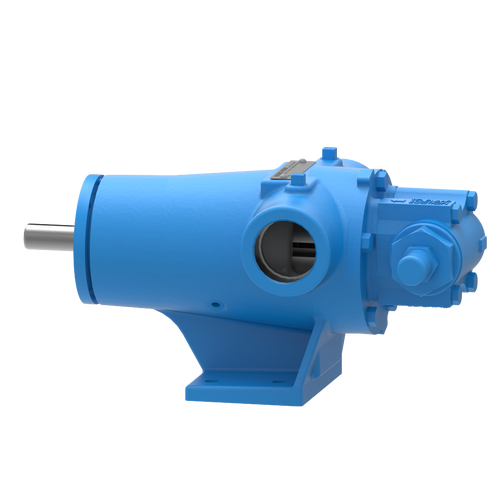

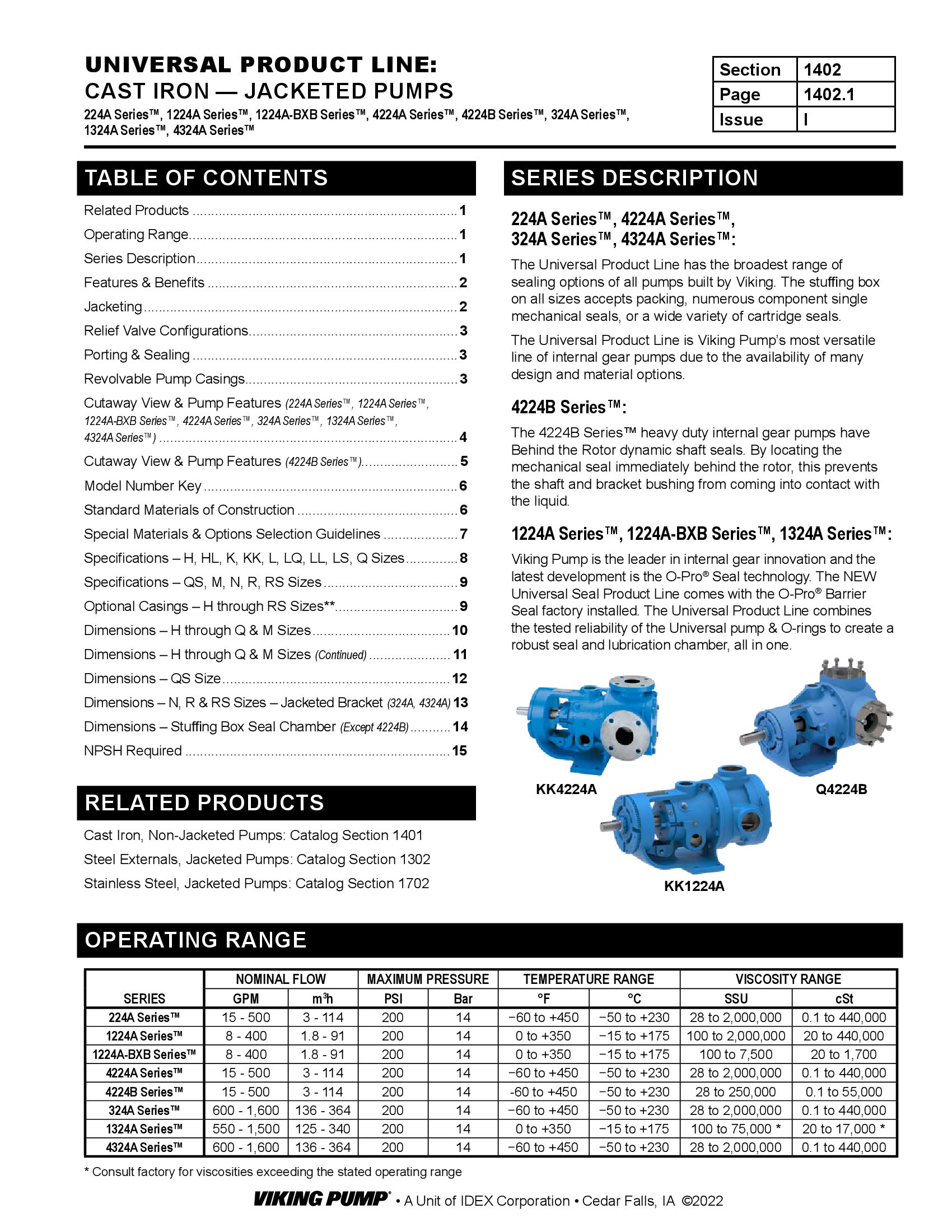

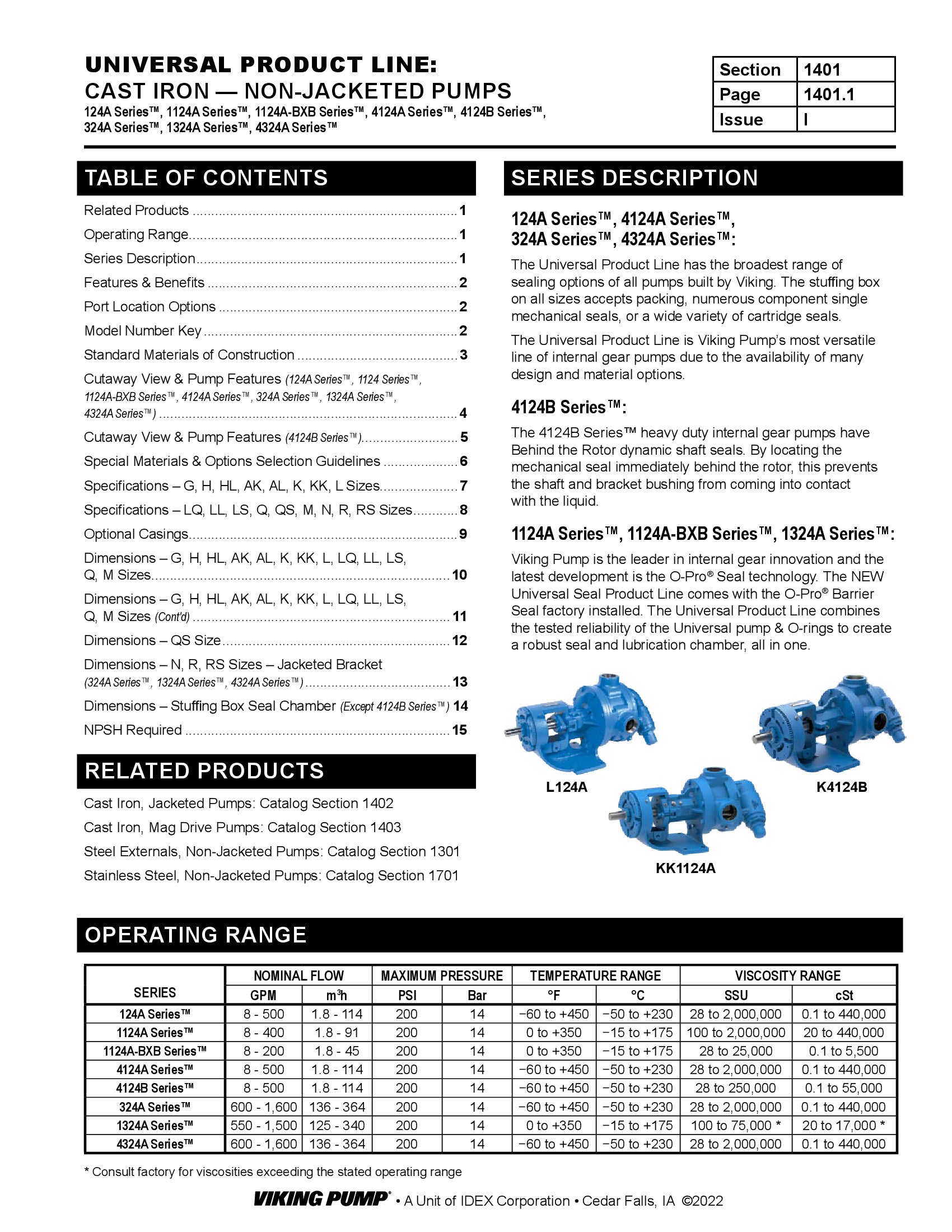

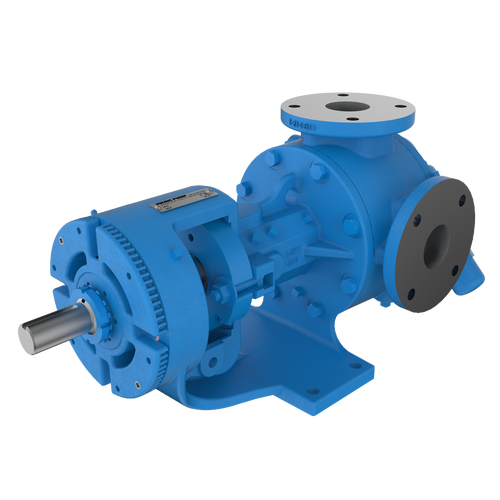

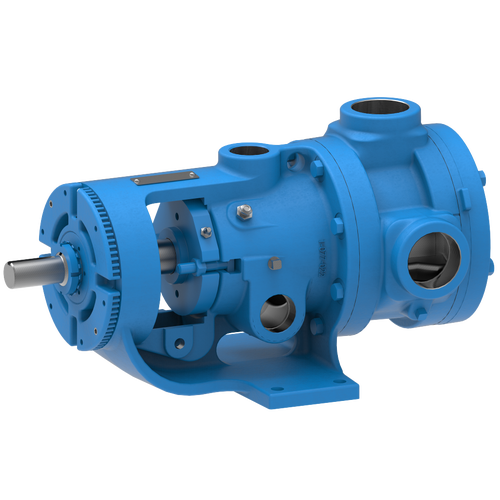

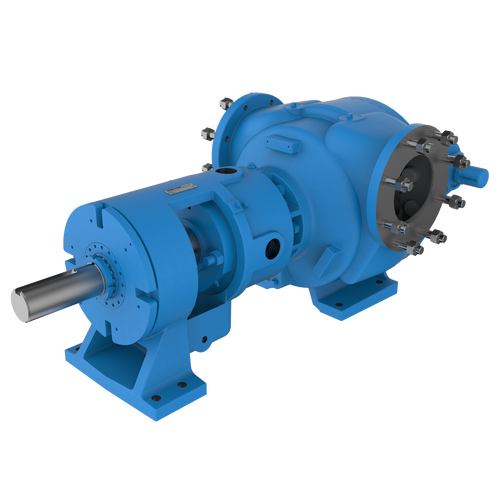

The 1324A Series™ internal gear pump with O-Pro® Seal technology is the perfect solution for liquid sugars, refined fuels, edible oils, and more due to it's reliable sealing as well as easy maintenance. It can handle flows from 500 to 1500 GPM (125 to 340 m³/h).

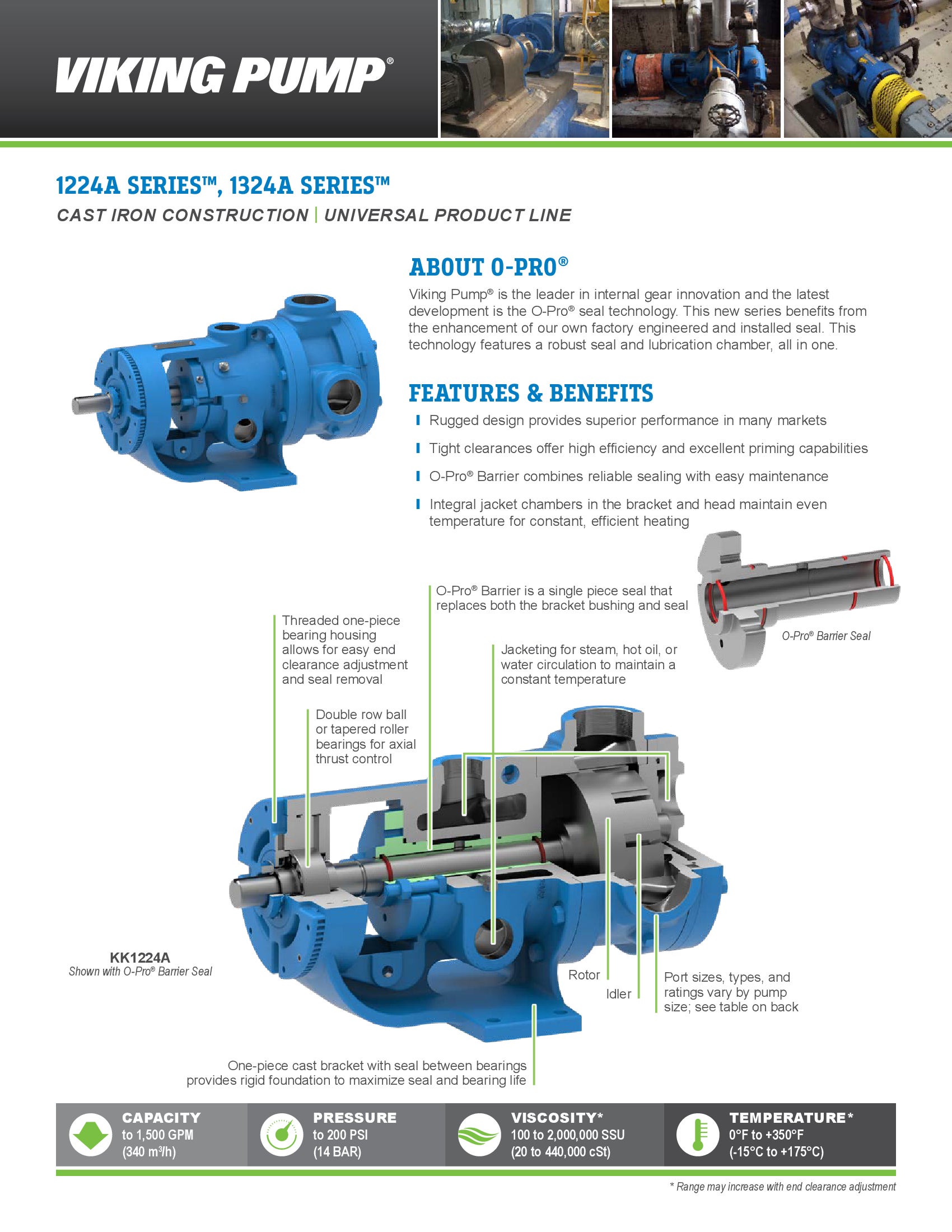

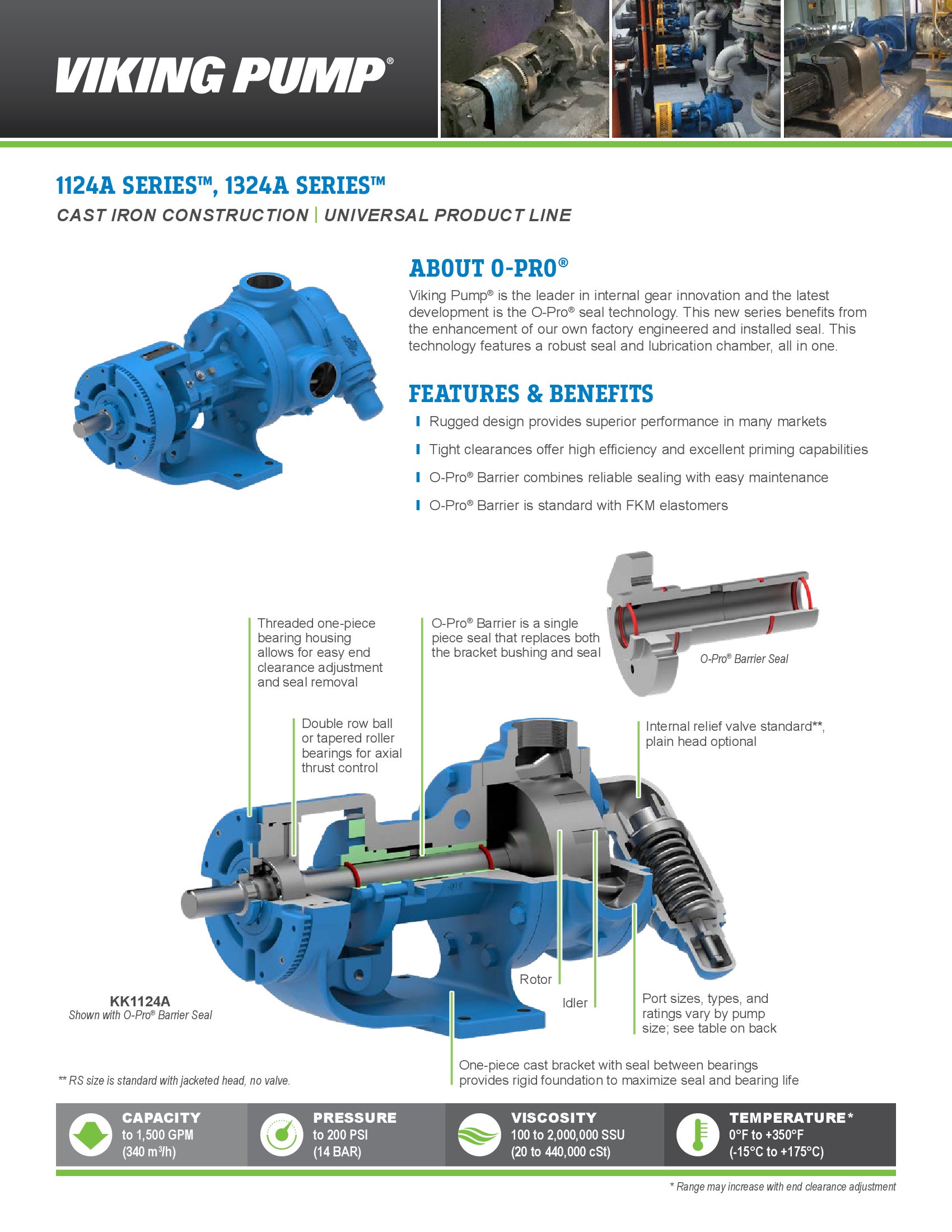

Features & Benefits

- Rugged design provides superior performance in many markets

- Tight clearances offer high efficiency and excellent priming capabilities

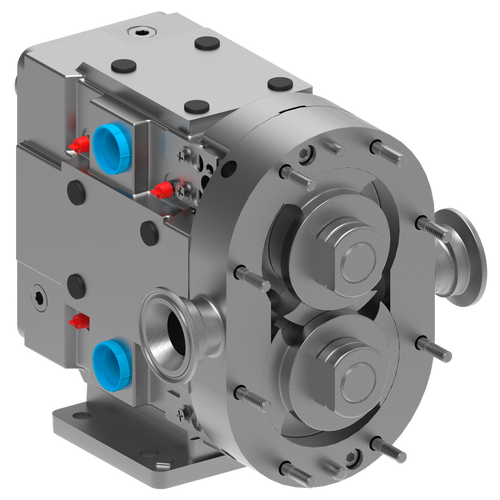

- O-Pro® Barrier combines reliable sealing with easy maintenance

- O-Pro® Barrier is standard with FKM elastomers

Capacity

500 to 1500 GPM

125 to 340 m³/h

Viscosity

100 to 75,000 SSU

20 to 17,000 cSt

Pressure

to 200 PSI

to 14 Bar

Temperature

0 to +350 °F

-15 to +175 °C

Opcions

Porting

Drives

Mounting

Sealing

Specifications

| Model | Standard Port Size | Nominal Pump Rating (GPM) | Nominal Pump Rating (m3/h) | Maximum RPM | Maximum Pressure PSI | Maximum Pressure BAR |

|---|---|---|---|---|---|---|

| N1324A | 6 | 550 | 125 | 330 | 200 | 14 |

| R1324A | 8 | 1000 | 227 | 260 | 200 | 14 |

| RS1324A | 10 | 1300 | 295 | 260 | 125 | 8.5 |

Videos

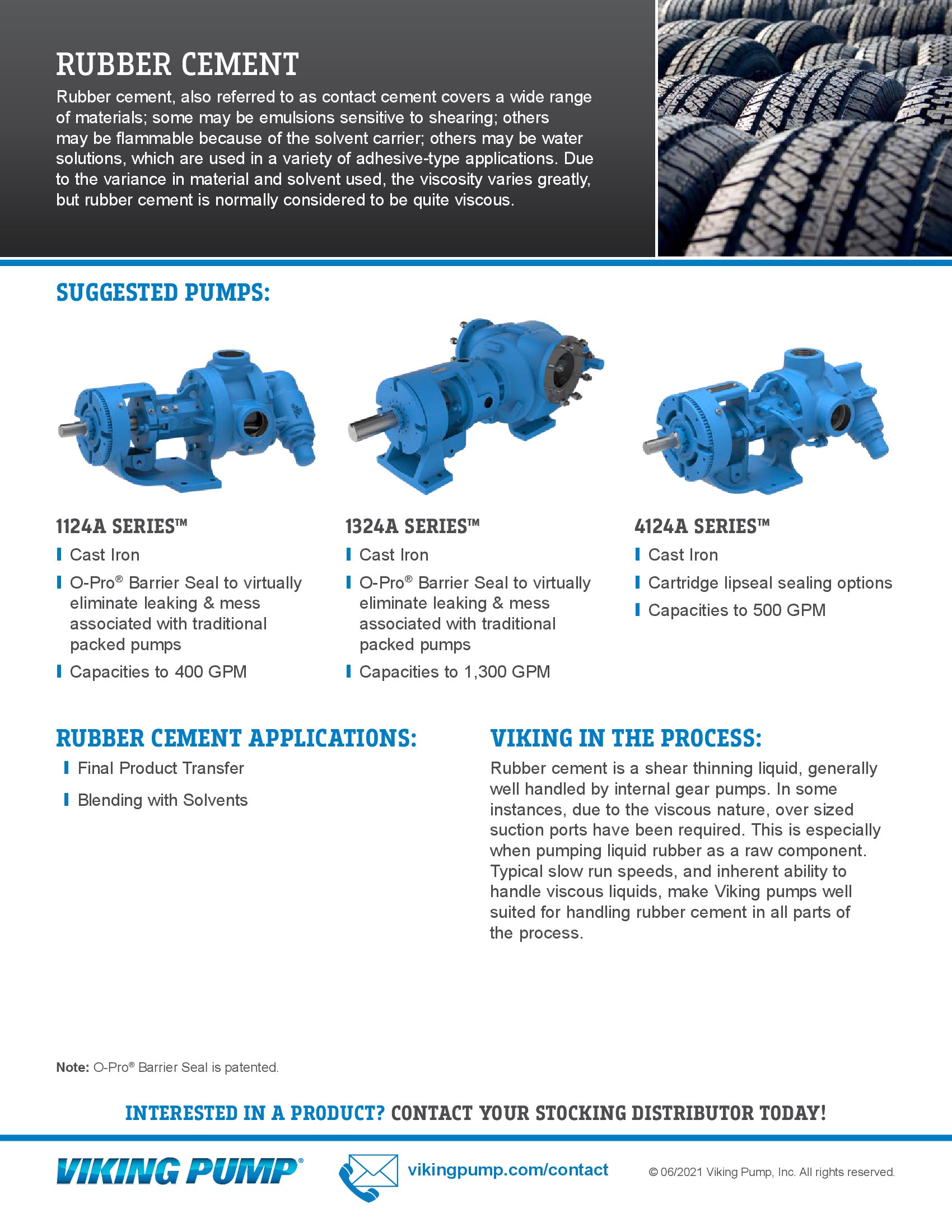

Adhesives

Adhesives are a group of substances, such as cement, glue, mucilage, and paste that are capable of holding materials together by surface attachment. Adhesives are made from many different basic materials, among them dextrin, latex, silicones, liquid rubber, resin, sodium silicate, and starch.

Starch

Starch is derived from corn, arrowroot or potatoes. It is shear sensitive (thickens) and viscosity varies from a few centipoise to over 20,000 cP depending on the type of starch, concentration in the liquid, and temperature.

Resins

Resins are high viscosity liquids with potentially shear sensitive (thinning) components, and made up of solvents, waxes, surfactants, and semi-solid resin particles all with various chemical compatibility concerns. These resins can be used in polyurethanes, epoxies and other adhesives. In some cases, resins contain pigments that bring with them abrasive wear concerns.

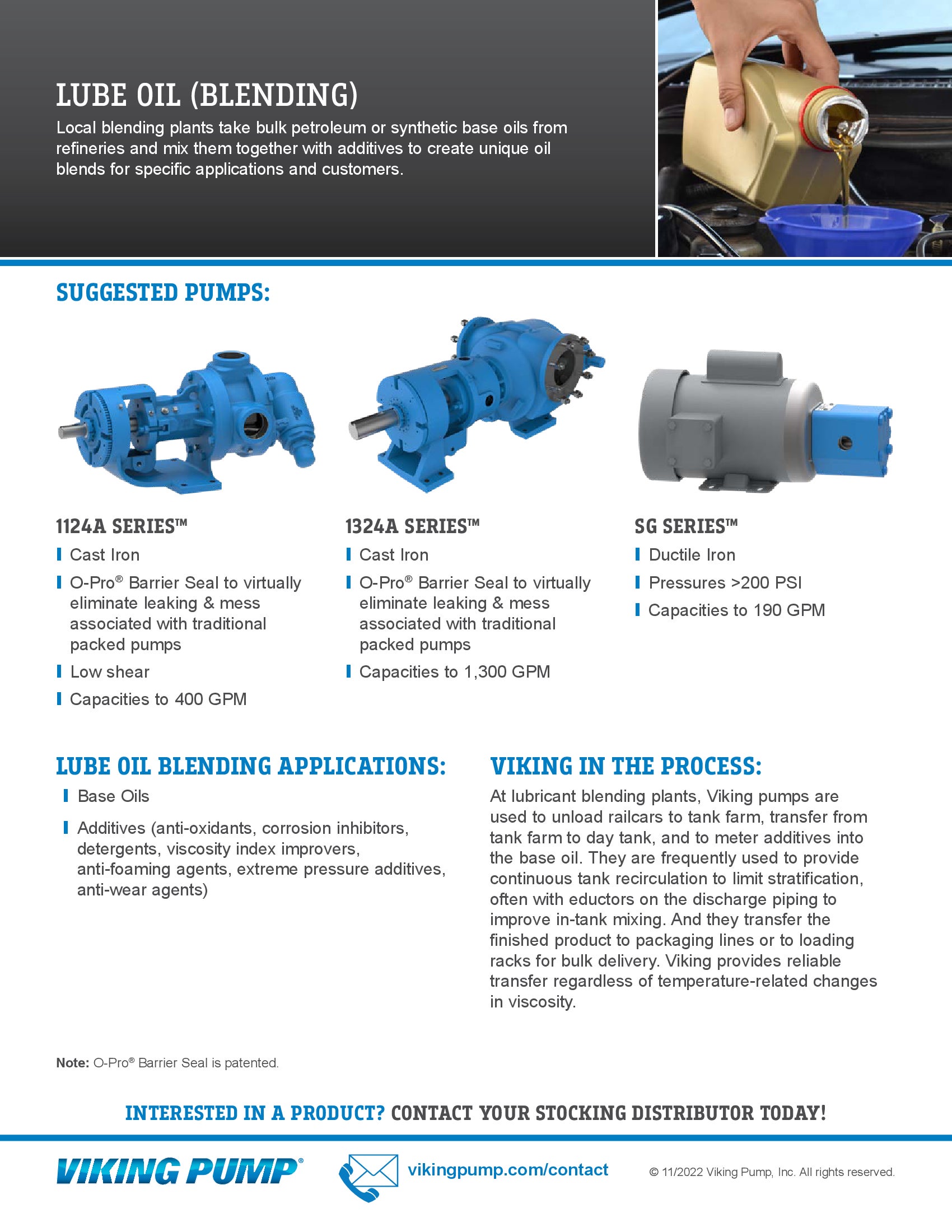

Refined Fuels

Refined fuels would include petroleum based fuel oils and some Jet Fuels. Their viscosity and temperature handled can vary greatly. Normally these are handled in bulk transfer operations.

Technical Service Manuals

Catalog Sections

Catalog Sections

Product Flyers

Product Flyers

-

Repair Resources

Viking Pump: Converting to the O-Pro® Barrier Seal O-ring Replacement: O-Pro® Barrier Seal

-

DRAWINGS

N1324A with Relief Valve - 6" Class 125 ANSI Opposite PDF

STEP

N1324A with Jacketed Relief Valve - 6" Class 125 ANSI Opposite PDF

STEP

N1324A with Plain Head - 6" Class 125 ANSI Opposite PDF

STEP

N1324A with Jacketed Head - 6" Class 125 ANSI Opposite PDF

STEP

N1324A with Plain Head - 5" Class 125 ANSI LH PDF

STEP

R1324A with Jacketed Head - 8" Class 125 ANSI Opposite PDF

STEP

R1324A with Relief Valve - 8" Class 125 ANSI Opposite PDF

STEP

R1324A with Plain Head - 10" Class 125 ANSI Opposite PDF

STEP

RS1324A with Jacketed Head - 10" Class 150 ANSI Opposite PDF