Overview

INNOVATIVE PUMPING SOLUTIONS FOR ANY APPLICATION

Viking Pump, a Unit of IDEX Corporation, leads the world in the design and manufacture of rotary positive displacement pumps for use in some of the toughest applications. Since 1911, our innovative products have been key contributors to successful operations in virtually every industry—from military, to food and beverage, to chemicals, fuels and plastics—reliably pumping materials that are thin, thick, hot, cold, liquid, solid, etc.

We offer a wide range of pump models, sizes and composition, as well as customized, fit for purpose options, to meet your strictest requirements. But, it’s not just about selecting a pump from the catalog. To provide the highest quality results and ensure the right pump for the right application, our specialized Engineering team applies its accumulated knowledgebase and expertise to perform:

-

Site-specific problem-solving

-

Full product testing (performance, hydro, pneumatic, NPSHr, sound, and vibration)

-

Further testing, upon request (magnetic particle, dye penetrant, traceability, and positive material identification)

-

Liquid sample analysis (rheology testing and elastomeric compatibility)

-

Quality control of all finished products

Our newly expanded lab and 3-D printing capabilities streamline our testing and new product development practices, allowing for faster and more efficient solutions and testing.

In 2020, Viking Pump joined forces with a fellow IDEX business unit Wright Flow Technologies and began selling a leading hygienic line of products produced by Wright Flow Technologies. This broad line combines local engineering and global distribution with 40 plus years of market expertise and solutions for hygienic applications. The expansion of offering rotary lobe, circumferential piston and centrifugal pumps rounds out a range of product solutions to meet customer’s needs.

Furthermore, we have an outstanding network of “local” stocking distributors around the world who are standing by to assist you. Their team members are trained by our engineers to provide the technical, service and sales support you need. They also have specialized application engineers to help with your particular situation. It’s easy and efficient to contact these authorized distributors directly with confidence in knowing we have shared our 100+ years of experience with them.

Viking can save you time and money by helping you make the best pump decisions.

OUR HISTORY

FROM ONE PUMP IN AN IOWA QUARRY TO MILLIONS OF PUMPS WORLDWIDE

Viking Pump was founded on a unique “gear within a gear” pumping principle invented by Jens Nielsen, who emigrated from Denmark to Cedar Falls, Iowa in 1870. The following timeline charts the course of Viking’s successive developments and response to historical events, which led to becoming the company it is today.

-

1904 | Jens Nielsen, a Danish immigrant, developed a quarry in what is currently the downtown Cedar Falls area. When water started getting into the quarry, he began developing drawings of his original pump.* With the help of an employee, George “Shorty” Mathes, the first-ever rotary internal gear pump was built and patented in the same year.

-

1911 | Nielsen partnered with three fellow immigrants P.C. Peterson (a machinist), W.L. Hearst (a doctor) and George Wyth (a shoe salesman) to form Viking Pump Company … named after the Vikings, who were the first European explorers of North America. In that first year, they manufactured fifty pumps, which generated revenues of two thousand dollars.

-

1920’s | Viking Pump experienced an acceleration in growth due to successfully meeting the needs of the oil industry in their efforts to transport by railroad tank car. This need enabled the company to stay ahead during the Great Depression and beyond.

-

1930’s | Petroleum processing led to a higher demand for Viking Pumps products. During WWII, the company won government contracts and the pumps were used in a multitude of military applications, including tanks and ships.

-

1950’s | Viking Pump expanded its international distribution. The company continued to launch new products in order to meet the needs of its customers.

-

1970’s and 1980’s | Viking Pump continued to focus on expansion and innovation, including the opening of a manufacturing facility in Shannon, Ireland.

-

1989 | Viking Pump was purchased by IDEX Corporation and is still a vital component of the IDEX Fluid and Metering division.

-

1990’s | Viking Pump furthered its world-wide presence, by acquiring Viking Pump Canada and appointing its first distributor in China.

-

2000’s | Launch of new sales channel, OEM. Original Equipment Manufacturer partners incorporate our product into their system design for resale. They have a high-quality requirement of product and may require unique solutions.

-

2010’s | With a strong emphasis on customer needs and targeted growth, Viking Pump delivered a line of Oil & Gas products for Pipeline Injection projects. Additionally, the patented sealing solution, O-Pro® rolled out across the globe as a solution to leaking pumps.

-

2020’s | Viking Pump expanded its product portfolio to include a line of rotary lobe, circumferential piston and centrifugal to serve the food & beverage, personal care, and bio-pharmaceutical industries in partnership with fellow IDEX business unit, Wright Flow Technologies.

-

Today | We have a global manufacturing, sales and service footprint with Viking pumps in over 200 countries and on all seven continents.

OUR PARENT COMPANY - IDEX CORPORATION

VIKING PUMP A MEMBER OF THE IDEX FAMILY OF COMPANIES SINCE 1989

IDEX (NYSE: IEX) is a company that has undoubtedly touched your life in some way. In fact, we make thousands of products that are mission-critical components in everyday activities. If you or a family member is battling cancer or another life-threatening disease, your doctor may have tested your DNA in a quest to find the best-targeted medicine for you. It’s likely your DNA test was run on equipment that contains components made by our IDEX Health & Science team. You can enjoy fresh fruits and vegetables thanks in part to Banjo, an IDEX company. Banjo valves are used on the agriculture sprayers that apply fertilizer on crops. And if you were ever in a car accident, the Hurst Jaws of Life®/LUKAS® tool may have rescued you.

Founded in 1988 with three small, entrepreneurial manufacturing companies, we’re proud to say that we now call 40 diverse businesses around the world part of the IDEX family. With more than 7,000 employees and manufacturing operations in 20+ countries, IDEX is a high-performing, global $2+ billion company committed to making trusted solutions that improve lives. For more information, visit www.idexcorp.com.

IDEX Corporation U.K. Modern Slavery Act Statement

Supplier Code of Conduct

OUR FACILITIES

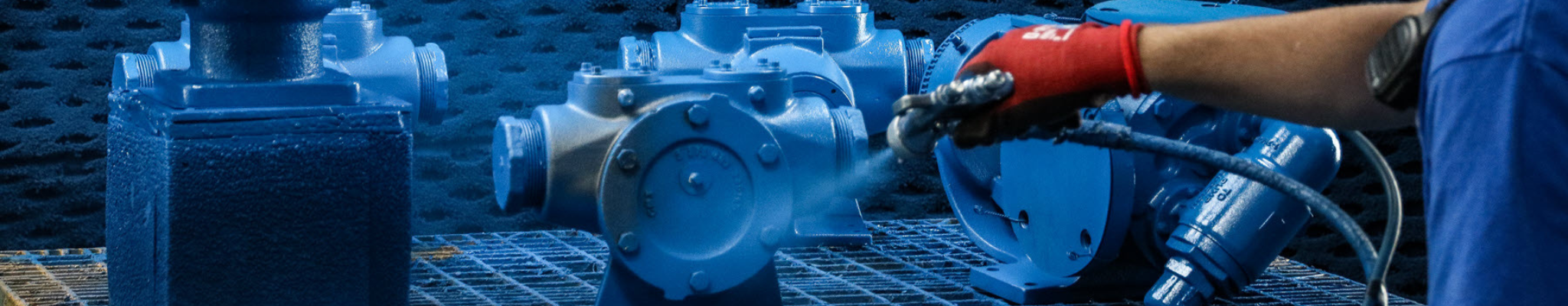

WE DO IT ALL, FROM CAST TO FINISHED PRODUCT

Viking Pump has four wholly-owned facilities in Cedar Falls, Iowa that are located in close proximity to each other. This maximizes the efficiency of inter-department collaboration, end-to-end workflow processes and quality control. It also enables us to deliver customized pumps to your exact specifications in a timely, cost-effective manner. Our current facilities include:

-

Headquarters – The headquarters is in a downtown Cedar Falls building dating back to the company’s inception, now renovated and expanded to meet today’s growing business.

-

Machine Shop and Foundry – Both of these facilities are located nearby in the Industrial Park on Viking Road, where pumps are assembled, painted and shipped to clients around the globe.

-

Hygienic Production – The hygienic product manufacturing takes place both in Cedar Falls, Iowa, as well as Eastbourne, England.

EMPLOYMENT

SATISFIED EMPLOYEES MAKE LOYAL EMPLOYEES

Click here to view all job openings at these Viking Pump, Cedar Falls, IA locations.

Viking Pump is one of the largest employers in the Cedar Valley with more than 500 employees, whose strong knowledge of industrial pump applications and products will meet or exceed your expectations. The following teams are here to serve you:

-

Engineering team – highly trained, specialized engineers who draw from many years of experience and familiarity with 1,400+ types of liquids pumped, which allows for comparison of the best pumps and materials for your liquid.

-

Manufacturing team – qualified workers who follow an integrated production process, from raw materials to finished product, in accordance with ISO 9001:2015 quality standards, and using Six-Sigma and Lean Kaizen tools.

-

Customer solutions group – application, sales and design engineers, who develop unique pumping solutions for both OEM manufacturers and pump end users with special requirements.

- Local application support & service – over 245 authorized distributors in 68 countries with extensive inventories of pumps and parts for quick solutions.

You can also view other IDEX Corporation open positions here.

IDEX in an equal opportunity employer Minorities/Females/Protected Veterans/Disabled