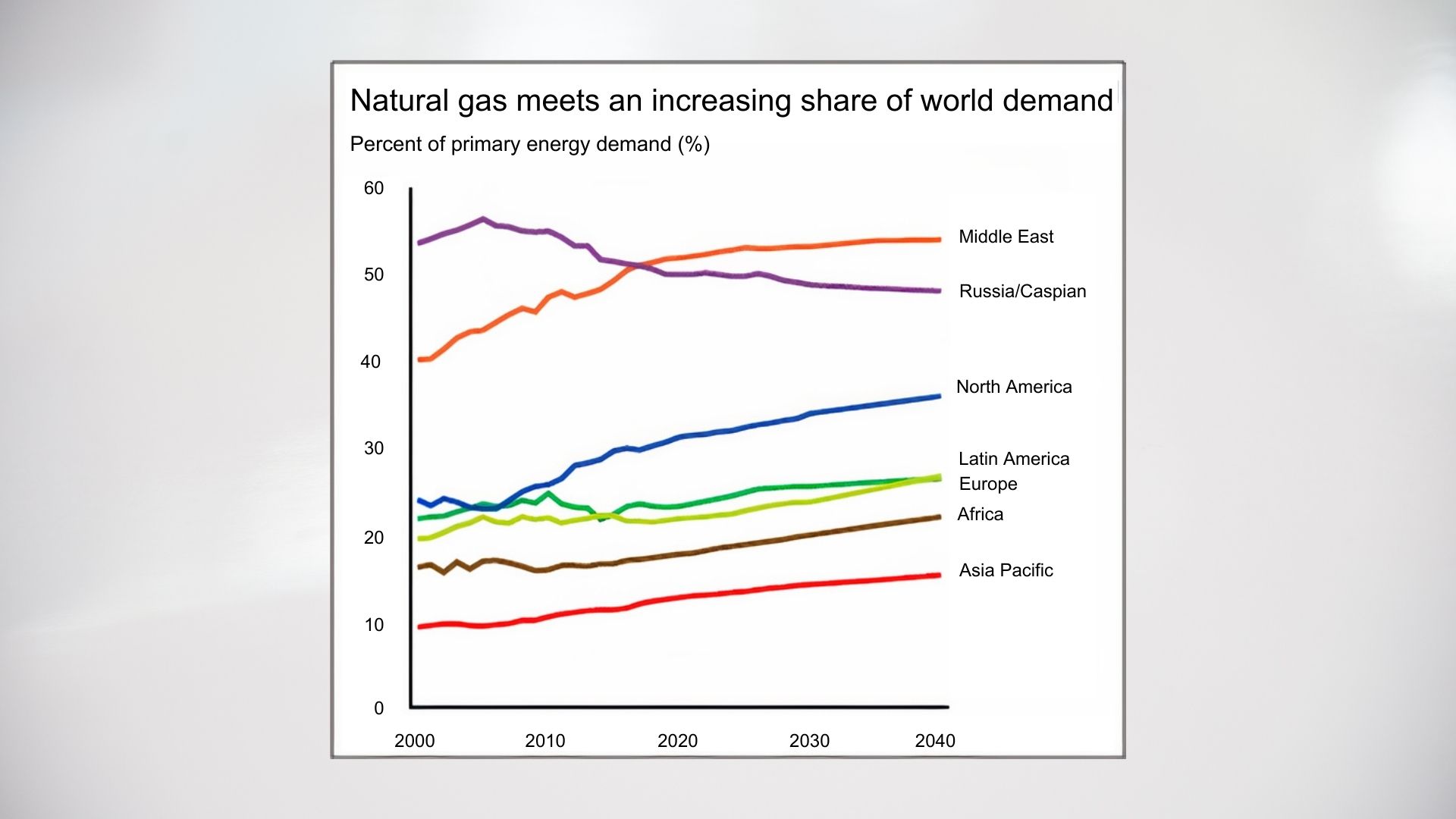

Industrial gear pumps have many uses in a wide array of market applications—ranging from food processing to pouring asphalt. A growing area in need of specialized gear pumps is in the oil and gas industry, particularly with regards to the removal of water from natural gas via dehydration. Viking Pump entered this market to support customers striving to deliver high-quality product 24/7 to their end users in the face of rising global natural gas consumption. This increasing demand is expected to continue through 2040, due to population growth, coal displacement by cleaner energy, fracking, etc.

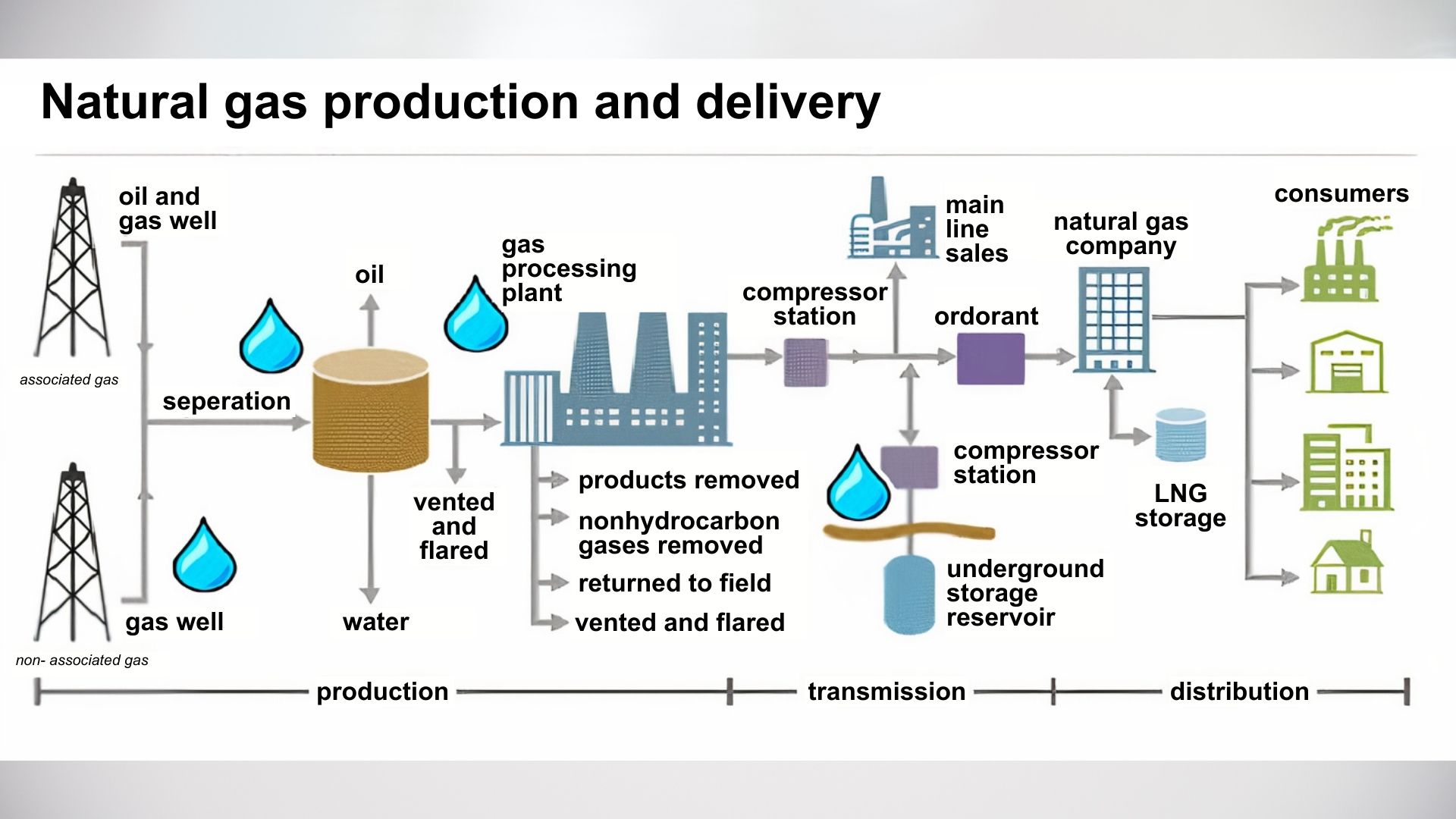

When natural gas is produced from an underground reservoir, it is saturated with water vapor and might contain heavy hydrocarbon compounds, as well as non-hydrocarbon impurities. In its raw state, natural gas cannot be marketed and, therefore, must be processed to meet certain specifications for acceptable quality “pipeline” and “sales” gas. These days, triethylene glycol (TEG) dehydration, or simply glycol dehydration, is the most common method. The TEG is re-boiled/re-generated at temperatures exceeding 350° F, high temperatures can be tough on all of the components within the system, it also requires specially engineered pumps to operate in these challenging continuous duty dehydration systems.

Leveraging a long history of gear pump design expertise combined with research into this new market, we were able to develop a customized, innovative pumping solution to help optimize glycol dehydration operations, able to withstand Leveraging a long history of pump design expertise combined with research into this new market, we were able to develop a customized, innovative pumping solution to help optimize glycol dehydration operations, able to withstand demanding conditions with less downtime, longer duty cycle, and thus, lower cost. The Viking GL407 Series™ and GL410 Series™ pumps assist at different critical steps of the natural gas glycol dehydration process (indicated by blue gas flames in the diagram below).

These Glycol pumps have the same trusted Viking Pump external gear design we are known for. In addition, to serve this market, the pumps also have these additional features:

- Enhanced thermal capabilities for easier startup

- Overall higher temperature rating

- Fixed precision clearances

- Increased pressure capabilities with hardened internals, thus, minimizing wear and extending service life.

- Less susceptible to leakage due to mechanical seal

- Easy in-field replacement via motor mount

We have a lot to share on this topic. Refer to the following Viking Pump white papers:

Contact a Viking Pump representative with questions/concerns when specifying a pump for glycol dehydration applications.