PUMP SOLUTIONS

Heading

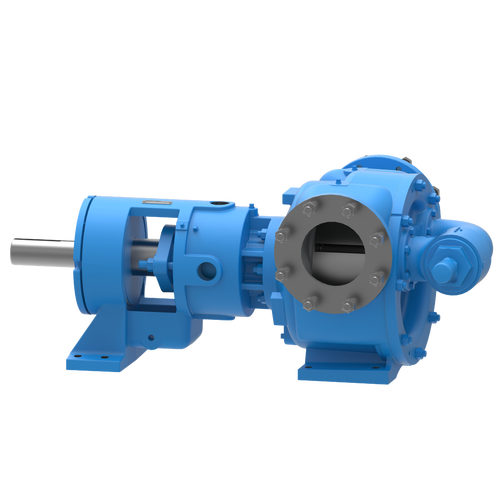

INDUSTRIAL SOLUTIONS

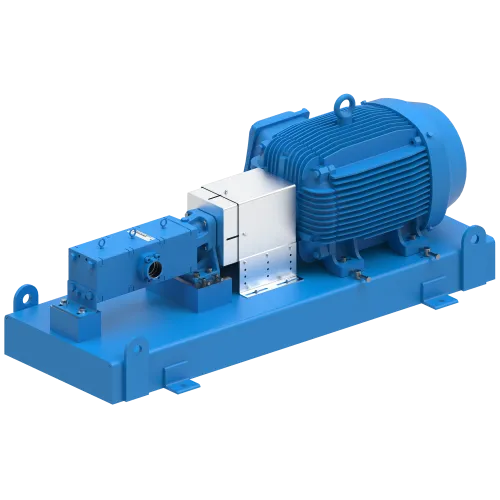

Viking Pump’s industrial gear pumps are the premiere positive displacement pump technology that covers nearly every pumping need.

Heading

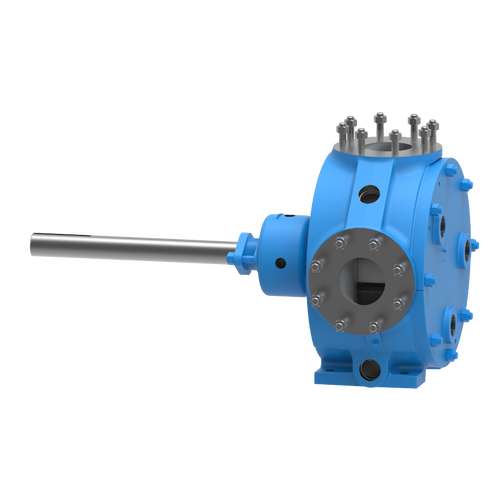

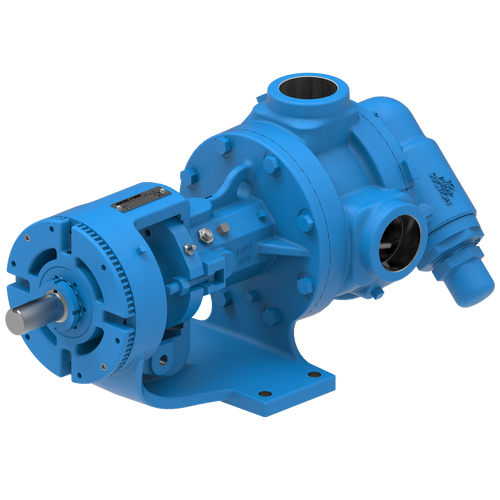

ENERGY SOLUTIONS

With construction options that have been proven to work for light, medium, and heavy-duty applications, the versatility and popularity of positive displacement pumps lie in their relatively simple design, high efficiency, and consistent flow rates.

Heading

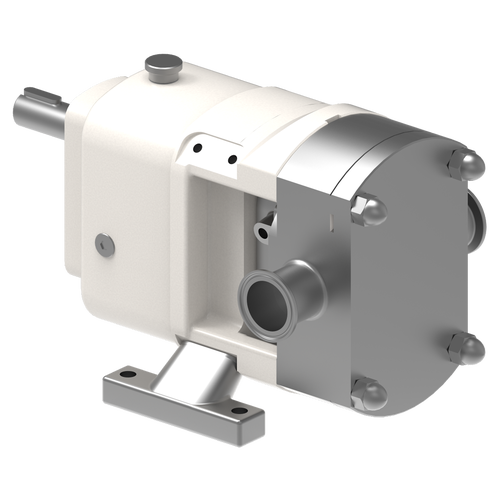

HYGIENIC SOLUTIONS

Viking Pump’s hygienic pumps offer the best efficiency and a wide range of porting, cleaning, and sealing options to meet your needs. In a business where cleanliness is key to reduce cross-contamination, we offer CIP (clean in place), SIP (sterilize in place), and COP (clean out of place) pumps to save you time and effort.

TECHNOLOGIES

Heading

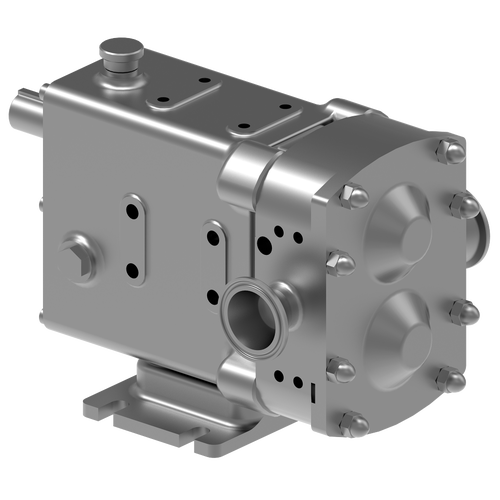

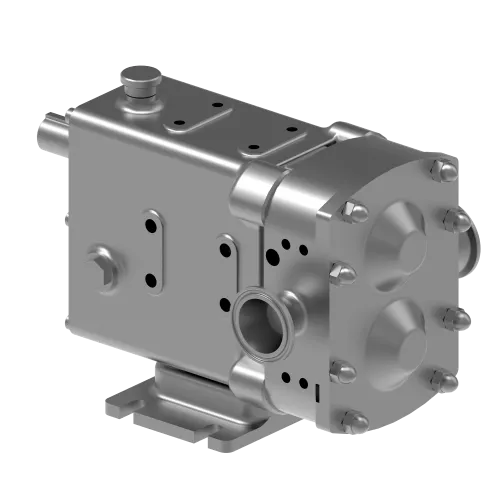

Internal Gear Pumps

Heading

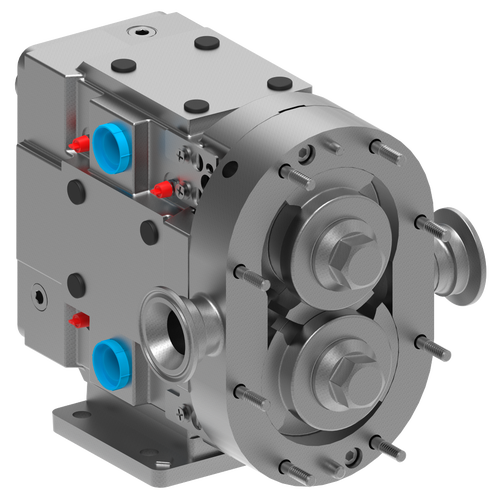

External Gear Pumps

Heading

Circumferential Piston Pumps

Heading

Rotary Lobe Pumps

Heading

Vane Pumps

FEATURED APPLICATIONS

Asphalt Cement

Clean asphalt contains no fillers and is an oil based liquid. It is primarily used in paving roads, waterproofing liquids, and paints. Typically they are handled at elevated temperatures to reduce the viscosity of the asphalt. The pump needs a source of heat like jacketing or electric heat to prevent the product from solidifying in the pump.

- Cast iron

- Electric heating prior to pump startup

- Capacities to 1600 GPM

- Cast iron

- Jacketed for steal/oil heating prior to pump startup

- Lower pressures

- Capacities to 450 GPM

Resins

Resins are high viscosity liquids with potentially shear sensitive (thinning) components, and made up of solvents, waxes, surfactants, and semi-solid resin particles all with various chemical compatibility concerns. These resins can be used in polyurethanes, epoxies and other adhesives. In some cases, resins contain pigments that bring with them abrasive wear concerns.

- Cast iron

- Abrasive resistant sealing option

- Hardened iron bushings and hardened steel shaft

- Low shear

- Capacities to 400 GPM

- Cast iron

- Sealing options available

- Hardened materials standard

- Capacities to 180 GPM

- 316 stainless steel

- Sealing options available

- Hardened material options

- Capacities to 320 GPM

Sauces

The term sauces covers a wide range of food products ranging from ketchup, mayonnaise, mustards, apple sauce and many other condiments.

- 316L stainless steel

- Mechanical seals

- 316L stainless steel

- Mechanical seals

- 316L stainless steel

- O Ring or mechanical seals

Creams (Medicinal, Cosmetic)

Creams are typically for personal use by consumers for cosmetic and surface medical treatments. Physical properties and chemistry can vary greatly depending on the cream base and added substituents. Some creams will be petroleum based like Petroleum Grease, while others may be emulsions suspended in water. They typically are shear-thinning mixtures.

- 316 Stainless Steel

- Cartridge lip seal options

- Low shear

- Capacities to 320 GPM

- 316 Stainless Steel

- O-Pro® Guard seal low shear

- Capacities to 320 GPM

- 316 Stainless steel

- Front loading seal

- Low shear

- Capacities to 761 GPM

LEADING THE WAY IN GLOBAL SERIVCE

From pump configuration support to competitive quotes, the support team provided by our local stocking distributors is the first step to complete your project. With the support of Viking's engineers, our team is ready to help you overcome your pumping challenges.

Articles & Case Studies

Reversing a Gear Pump

With Viking pumps the answer is usually “yes,” but before you turn that “reverse” switch on your pump’s motor starter or variable frequency drive, there are a number of things to consider, which are discussed here

Pump Choices in Chocolate and Confectionery Processing: Lobe/CP Pumps vs. Internal Gear Pumps

Unlike food processors who primarily use centrifugal pumps, chocolate and confectionery processors have two main preferences for handling viscous liquors, chocolates, sugars and other confectionery liquids: Rotary Lobe / Circumferential Piston (CP) pumps and Internal Gear Pumps. These Positive Displacement-type pumps are chosen due to various reasons. But which is best?

Viscosity Through Thick and Thin

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

U.S. EPA Bans Natural Gas-Driven Pumps

A new EPA rule, published December 2, 2023, covering new and existing oil and gas operations, requires the use of zero-emissions pumps instead of natural gas-driven pumps, with very few exceptions. It also restricts other natural gas-driven equipment, limits fugitive emissions and calls for reduced flaring of associated gas

ABOUT US

INNOVATIVE PUMPING SOLUTIONS FOR ANY APPLICATION

Viking Pump, a Unit of IDEX Corporation, leads the world in the design and manufacture of rotary positive displacement pumps for use in some of the toughest applications. Since 1911, our innovative products have been key contributors to successful operations in virtually every industry-from military, to food and beverage, to chemicals, fuels and plastics-reliably pumping materials that are thin, thick, hot, cold, liquid, solid, etc.