- Cast Iron

- O-Pro® Barrier Seal to virtually eliminate leaking & mess associated with traditional packed pumps

- Pump and seal capable of withstanding upset pressures to 250 psi

- Abrasive resistant hardened features

- High strength hardened steel shaft

- Low shear

- Capacities to 200 GPM

Starch Adhesive Applications are Challenging

- Pressure spikes damaging mechanical and lip seal components

- Downtime and costly repairs delaying production

- High-viscosity materials damaging pump internals

Viking Pump has the Answer

Our engineering team has developed the best positive displacement pump solution for those challenges you face with our 1124A-BXB Series™ gear pump with O-Pro® sealing technology.

- Reliable sealing with O-Pro®

- Minimal maintenance

- Withstands pressure spikes

- Handles a wide range of viscosities with ease at a flow rate to 200 gallons per minute

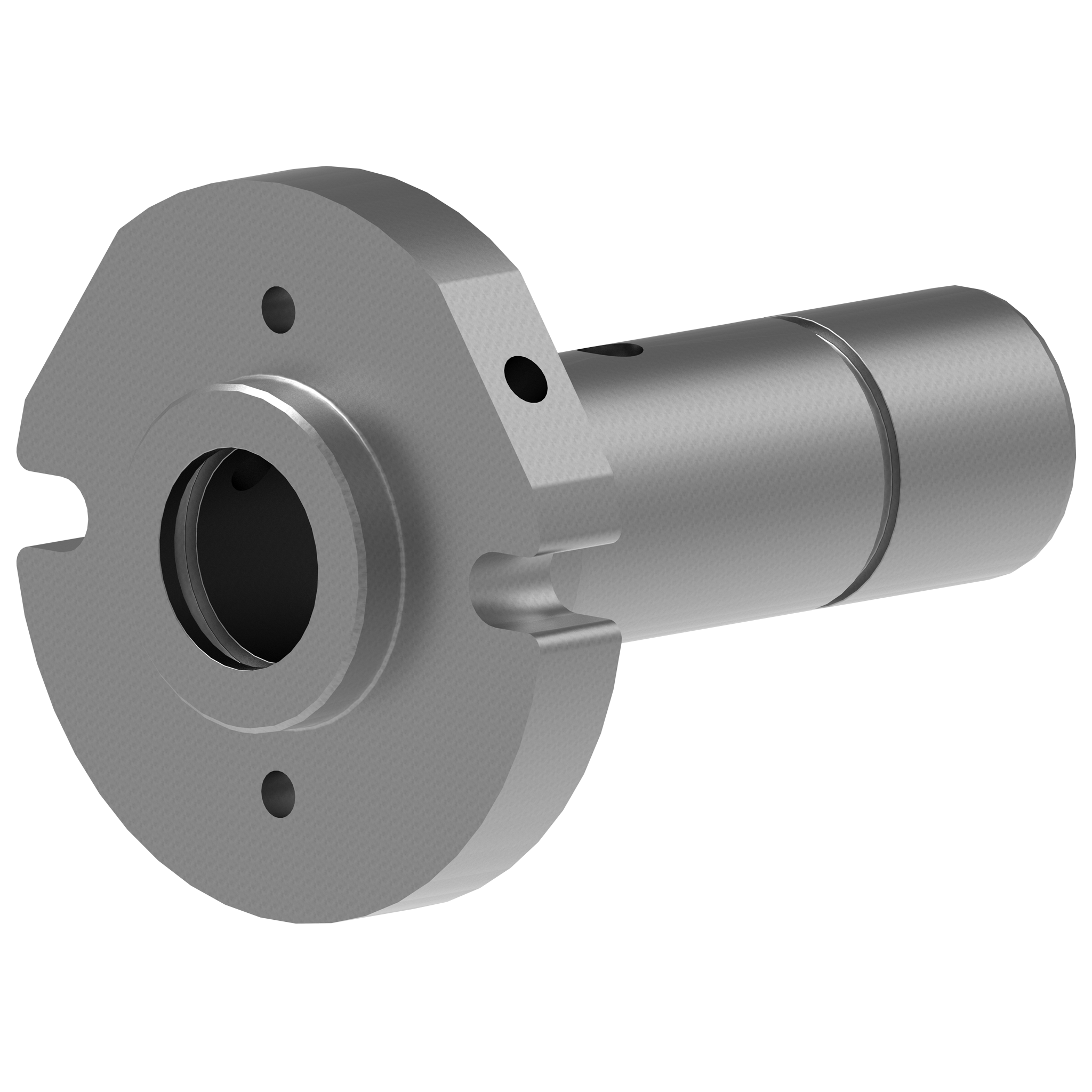

Replace Packing or Mechanical Seals with O-Pro®

Each O-Pro® Seal design option replaces packing or a mechanical seal by occupying the internal bracket cavity with a machined seal gland. Utilizing O-rings to seal externally on the bracket and internally on the shaft, a combination of O-rings and lubricating grease provide a robust seal. This prevents process fluids from leaking out of the pump.

With over 110 years of experience providing positive displacement pumping solutions, Viking Pump has a rich, lengthy history of providing engineered solutions for tough applications like corrugated cardboard. Our dedicated sales and field support specialists are supported by a team of customer service representatives and engineers plus a knowledgeable team of application engineers are available to help with product selection and technical support.

Viking Pump's commitment to innovation and performance has made us a leader in the industry. Our extensive product line offers an array of solutions for corrugated box manufacturers, from our high-performance pumps to our advanced engineering capabilities. With a variety of custom designs available, Viking Pump can help you optimize your production process and increase your bottom line.