With over 110 years of positive displacement pumping experience, Viking Pump® knows all about high viscosity fluids.

Resins are high viscosity liquids with potentially shear sensitive (thinning) components, and made up of solvents, waxes, surfactants, and semi-solid resin particles all with various chemical compatibility concerns. These resins can be used in polyurethanes, epoxies and other adhesives. In some cases, resins contain pigments that bring with them abrasive wear concerns.

Gear Pump Selection

The pump type for your viscous application matters. When it comes to thick liquids, gear pumps are hands down the perfect solution to keep your product moving.

Gear pumps, a type of positive displacement pump, aren't affected by upstream pressure changes. They have adjustable clearances as a standard that enables handling viscosities from 28 to 2,000,000 SSU (1 to 440,00 cSt). Our internal gear products are low-shearing to protect your liquids and a smooth, non-pulsating flow for accurate measurement or metering.

Heading

1124A Series™

- Flow Rate: 8 to 400 GPM (1.8 to 91 m³/h)

- Material: Cast Iron

- Sealing: O-Pro® Barrier Seal

Heading

4624B Series™

- Flow Rate: 0.75 to 182 GPM (0.17 to 41 m³/h)

- Material: Cast Iron

- Sealing: Mechanical Seal

Heading

4127C Series™

- Flow Rate: up to 320 GPM (to 73 m³/h)

- Material: Stainless Steel

- Sealing: Mechanical Seal

Typical Applications

Viking pumps are used in wide variety of resin handling applications. In most cases Viking pumps will be used for transfer and blending applications. Metering applications are also common. Pay close attention to run speed and operating temperature, as many resins are thermosetting. As such, often times abrasive resistant sealing options should also be considered.

Typical applications include:

Epoxy Resins

Phenolic Resins

Acrylic Resins

Whether you have a question or are ready to get a quote, let us know and we'll be in touch with you soon.

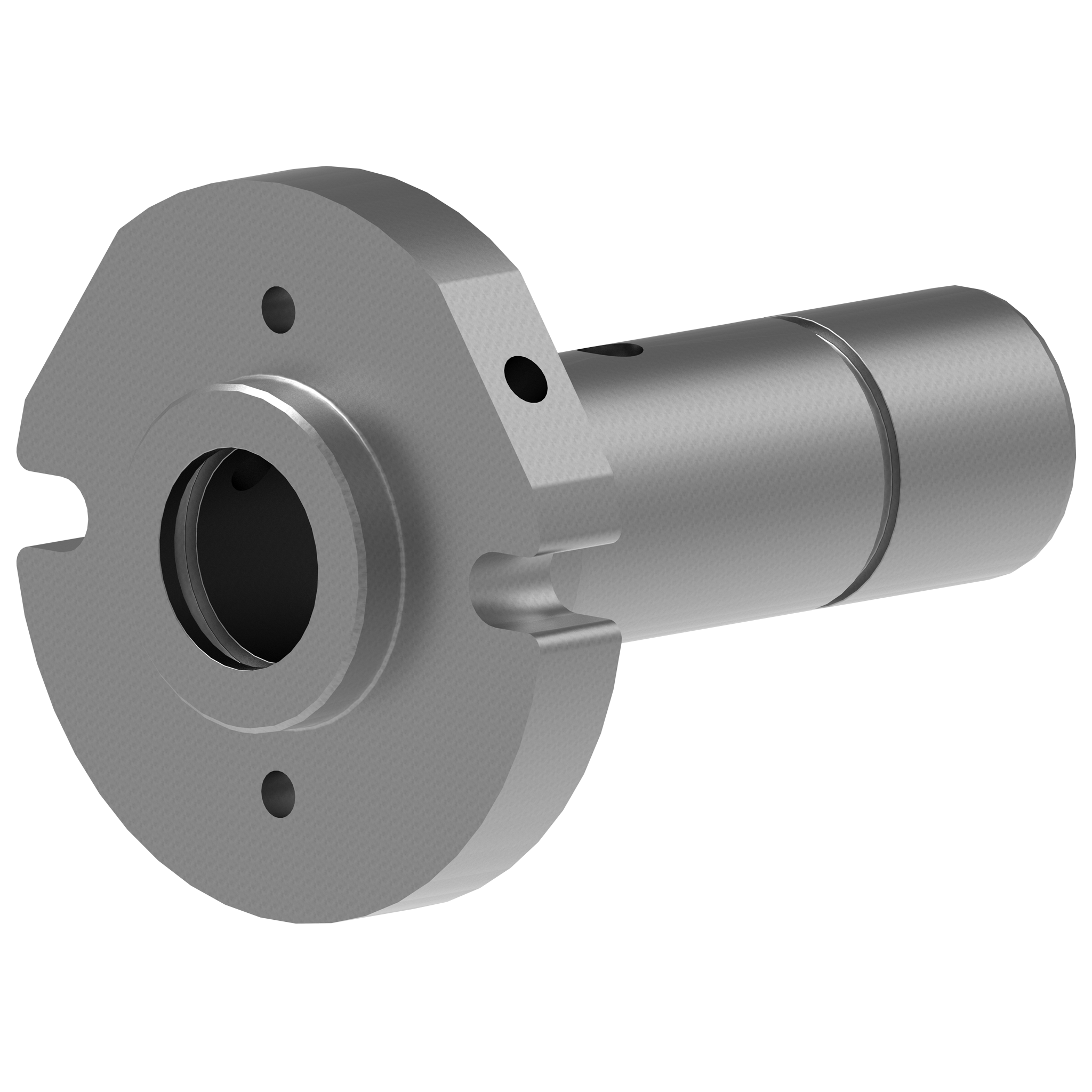

Replace Packing or Mechanical Seals with O-Pro®

Each O-Pro® Seal design option replaces packing or a mechanical seal by occupying the internal bracket cavity with a machined seal gland. Utilizing O-rings to seal externally on the bracket and internally on the shaft, a combination of O-rings and lubricating grease provide a robust seal. This prevents process fluids from leaking out of the pump.

With over 110 years of experience providing positive displacement pumping solutions, Viking Pump has a rich, lengthy history of providing engineered solutions for tough applications like resins. Our dedicated sales and field support specialists are supported by a team of customer service representatives and engineers plus a knowledgeable team of application engineers are available to help with product selection and technical support. Click here to connect with our team.

Viking Pump's commitment to innovation and performance has made us a leader in the industry. Our extensive product line offers an array of solutions for corrugated box manufacturers, from our high-performance pumps to our advanced engineering capabilities. With a variety of custom designs available, Viking Pump can help you optimize your production process and increase your bottom line.