Hot Melt

Positive displacement pumps are ideal for manufacturing hot melt due to their ability to handle highly viscous materials and maintain a consistent flow rate, which is essential in the production processes that require precise application and distribution. Unlike centrifugal pumps, positive displacement pumps are not affected by changes in viscosity, ensuring that hot melt adhesives and materials are delivered accurately and with minimal pulsation. This precision helps in maintaining the quality and performance of hot melt products, reducing waste and inefficiencies. Additionally, these pumps are robust and can effectively manage the high pressures and temperatures often associated with hot melt manufacturing, making them a reliable choice for industries focused on producing high-quality adhesive solutions.

Recommended Pumps

-

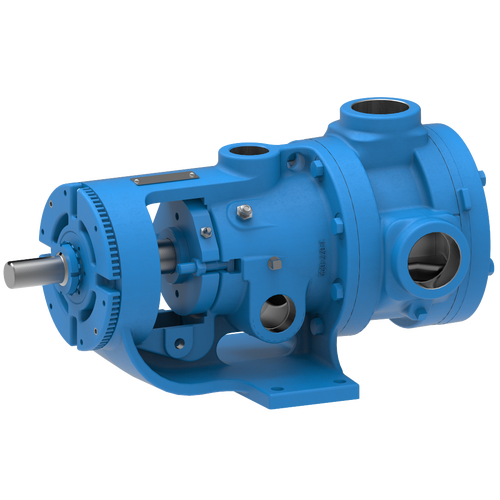

1224A SERIES™

- Cast Iron

- O-Pro® Seal

- 0-400 gpm | 1.8-91 m3h

-

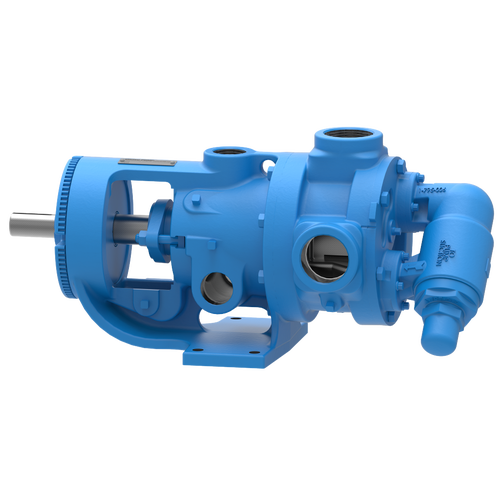

224A SERIES™

- Cast Iron

- Packing

- 0-500 gpm | 0-114 m3h

-

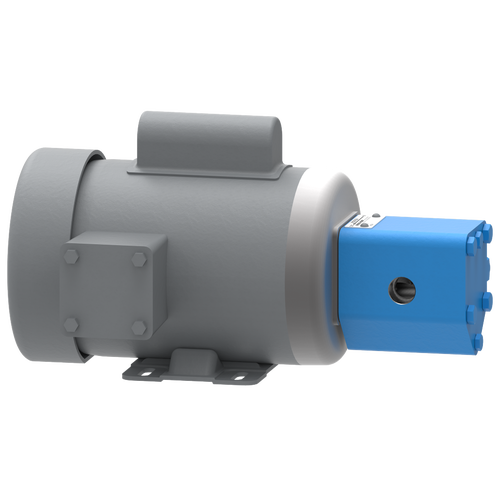

SG SERIES™

- Ductile Iron

- Mechanical Seal

- 0-190 gpm | 0-43 m3h

- How Pump Packing Works - AnimationIn this video, learn about pump packing and how it works.March 14, 2025

- 50 States / 50 Pumping Applications: Nebraska, Arizona, Virginia, Louisiana, MichiganSince our founding in 1911, Viking Pump has built over 7,000,000 pumps and supplied them to customers all over the world. These pumps handle the broadest range of liquids in the industry. We’ve prepared a listing of 50 Viking pump applications, tying each to a state where this application can commonly be found. Today let’s explore Viking Pump applications in Nebraska, Arizona, Virginia, Louisiana, and Michigan.March 14, 2025