Cheese

Cheese

Custom Content One

Cheese is made by curdling cultured milk using rennet, an enzyme which helps separate the solid curd from the liquid whey. The curd is then drained, shaped, salted, and aged to develop flavor and texture. Cheese can be from a wide range of milk sources to produce both hard and soft cheese with many regional variations.

Hygienic positive displacement pumps are ideal for manufacturing cheese for several reasons. Firstly, they are designed to handle delicate and viscous materials, such as cheese curd, without causing damage to the product. This is crucial in cheese manufacturing where the texture and consistency of the product are important. Secondly, these pumps provide gentle handling of products, ensuring that the structural integrity of the ingredients is maintained.

Additionally, hygienic positive displacement pumps are easy to clean and sterilize, which is essential in maintaining the strict hygiene standards required in food production. Their

design helps prevent cross-contamination and ensures that the processing environment remains sanitary. Finally, these pumps offer precise flow control, allowing for accurate dosing and mixing, which is critical in achieving the desired cheese qualities and consistency during production.

Custom Content One

Viking in the Process

Viking hygienic pumps are used by both industrial and artisanal cheese processors. They transfer raw milk from the silos to the pasteurizers, then to the stirred tanks. Bacterial starter cultures are added to ferment the lactose, followed by rennet, an enzyme that causes the milk to coagulate and curd to form. After cutting, stirring and heating to release whey, this byproduct is pumped to further processing such as drying or to waste. Remaining curd may be pumped into molds for pressing to remove excess moisture. Some cheeses may then be brined to protect against bacterial contamination and enhance flavor. Cheese is then aged where fermentation continues prior to packaging.

Custom Content Two

Applications

- Milk, whey and curd transfer

- Brine transfer and recirculation

Recommended Pumps

-

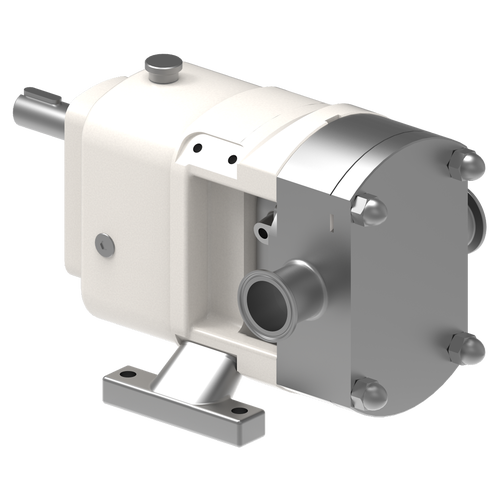

CLASSIC+ SERIES™

- Stainless Steel

- Mechanical Seal

- up to 832 gpm | up to 189 m3h

-

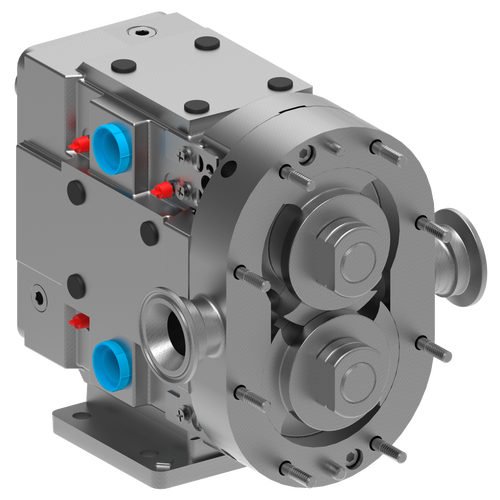

TRA®10 SERIES

- Stainless Steel

- Mechanical Seal

- up to 450 gpm | up to 102 m3h

-

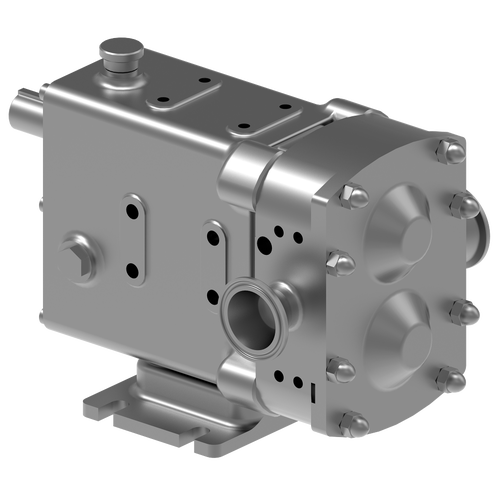

REVOLUTION® SERIES

- Stainless Steel

- Mechanical Seal

- up to 400 gpm | 1.8-91 m3h

Articles / Case Studies

There are really four main types of suppliers of hygienic, or sanitary pumps for food and pharmaceutical applications. There is no best source for everyone – each has advantages and disadvantages depending on your situation and budget. Here are some points to consider when choosing where to source your pumps.

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

Videos

- Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

- Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025