Custom Content One

Features & Benefits

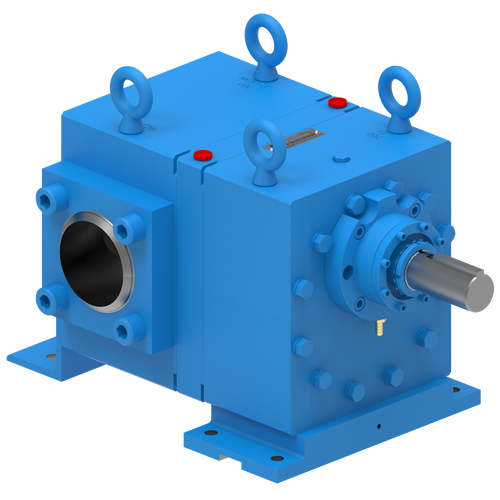

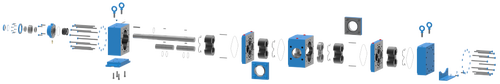

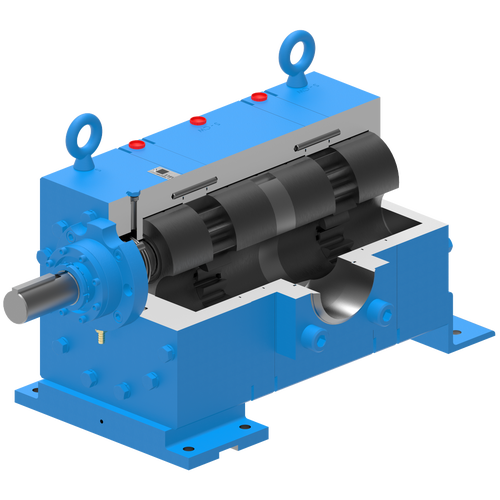

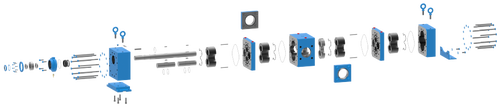

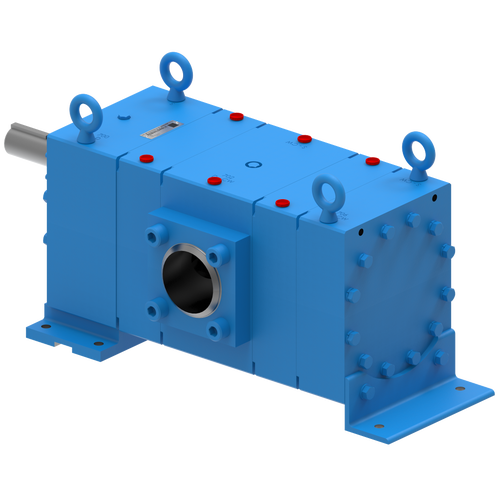

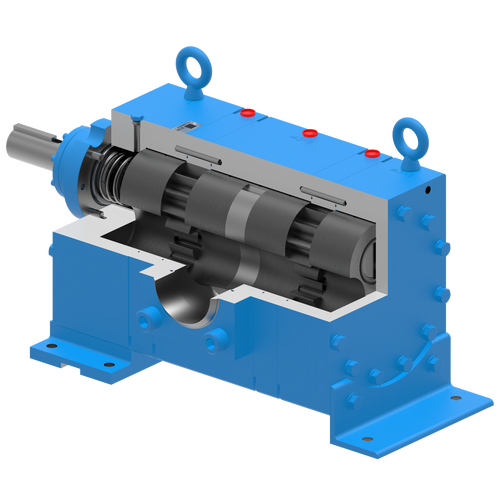

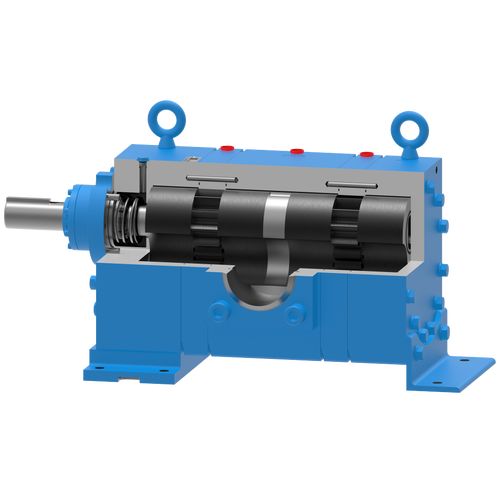

REBUILDABLE DESIGN & INCREASED DURABILITY

- New advanced materials on critical internal wear surfaces

- Enhanced wear resistance and durability extend pump life

- All internal wear components are replaceable

- Simple disassembly and reassembly process saves time and money

- Complete rebuild kit brings the pump back to as-new operating condition

REDUCED MAINTENANCE

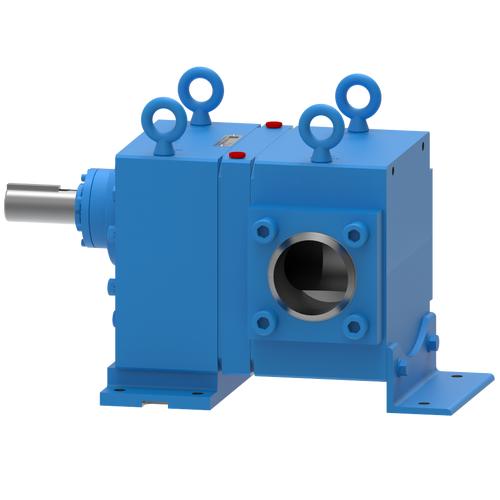

- Back pull-out Type 2 bellows seal design and spacer coupling eliminate the need to disturb piping or pump and motor placement during seal changes

- Robust axial thrust control bearing reduces premature seal failure due to elevated inlet pressure, starts, stops, and other unique application conditions

- Rigid structural steel base with milled mounting pads and jacking bolts for ease of field alignment

- No pulsation dampeners, gear reducers, belt drives, or additional equipment to service and maintain

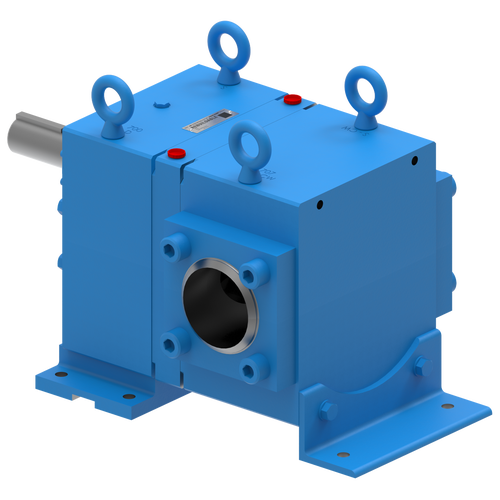

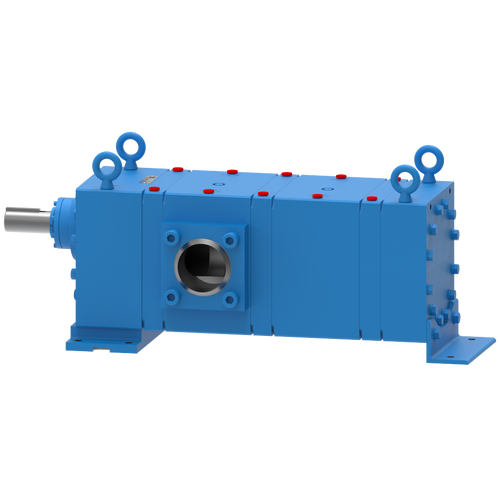

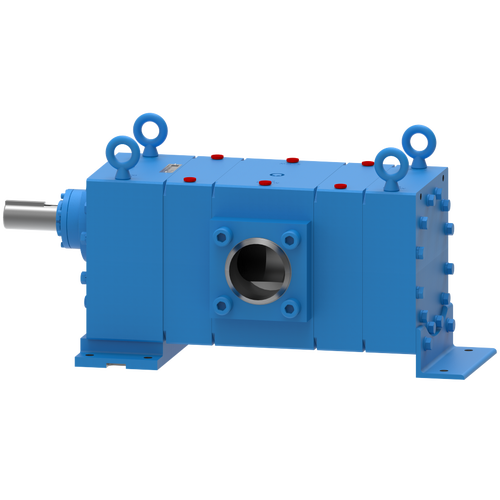

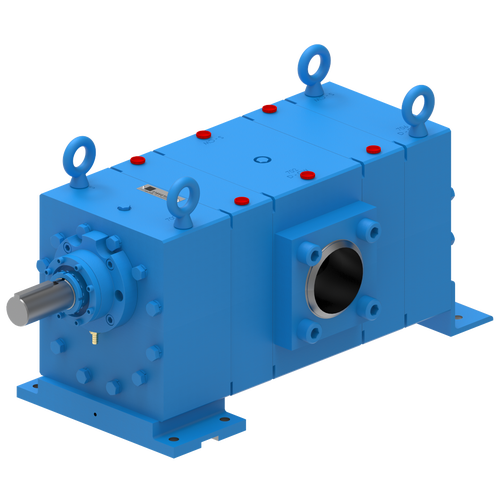

MODULAR PORT DESIGN

- 6”, 180° 3000 Series square flange ports standard

- Weldneck port adapter design allows for multiple interchangeable flange options

- Common Port Location (CPL) feature allows for installation of lower flow rate pumps when well production decreases without welding or piping modifications

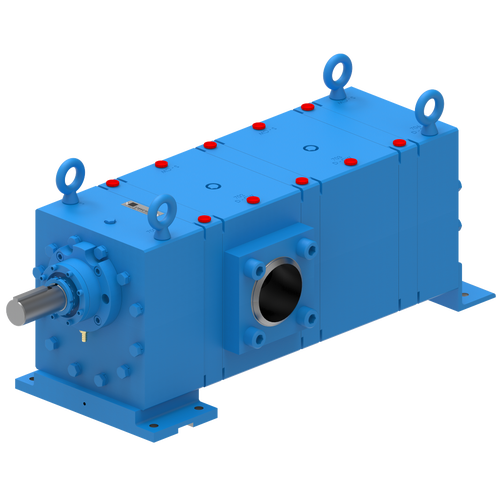

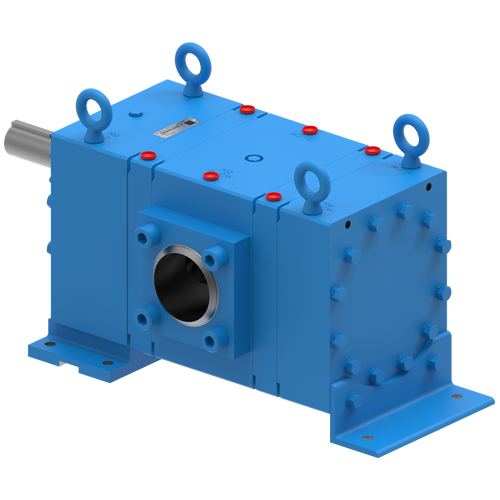

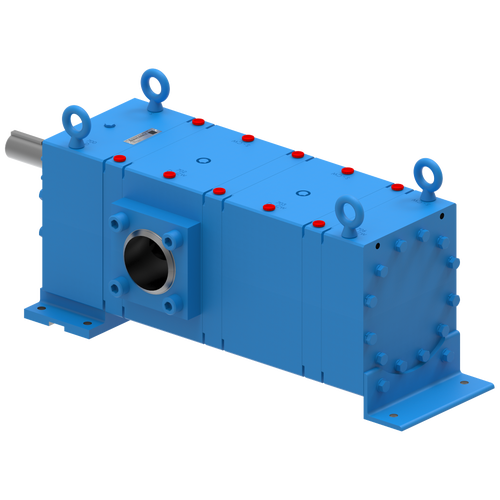

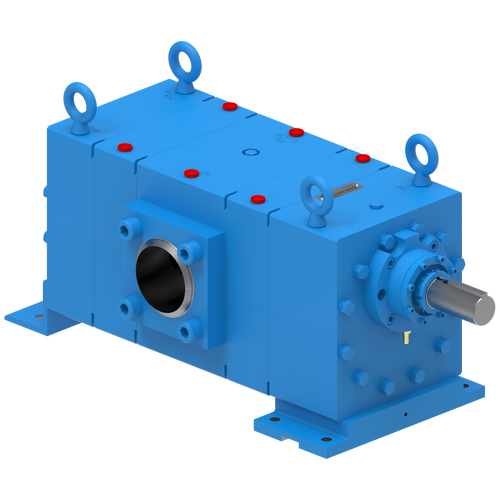

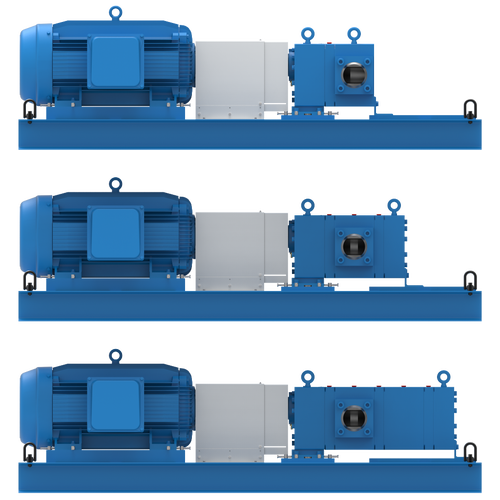

COMPACT FOOTPRINT

- 11’ unit length on largest pump and motor assembly for significantly smaller foot print than the competition

- Motor speed operation eliminates the need for gear reducers or belt drives

- Units include small, rigid formed steel baseplate complete with spacer coupling and coupling guard

Custom Content Two

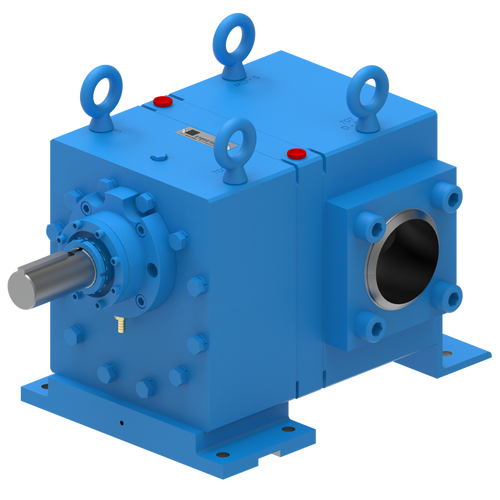

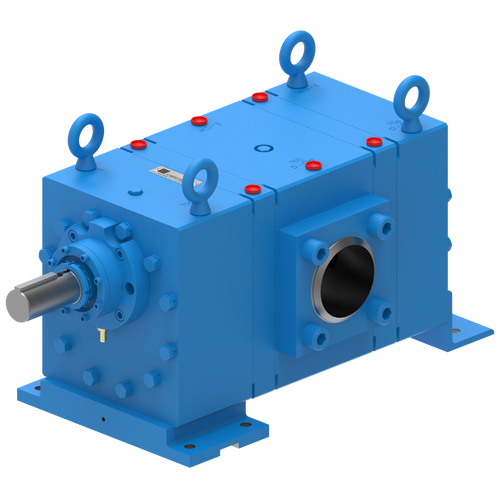

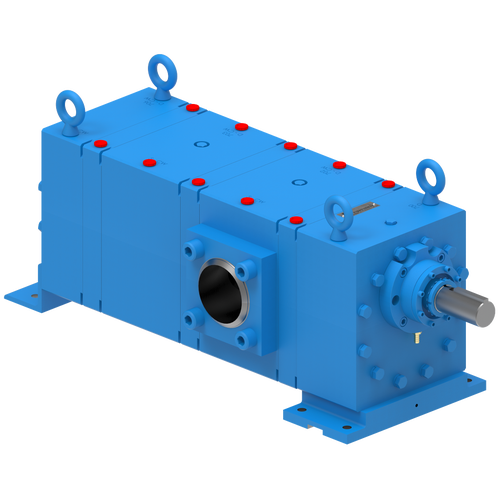

Image

Contact Viking Pump Energy Team

Contact Viking Pump Energy Team