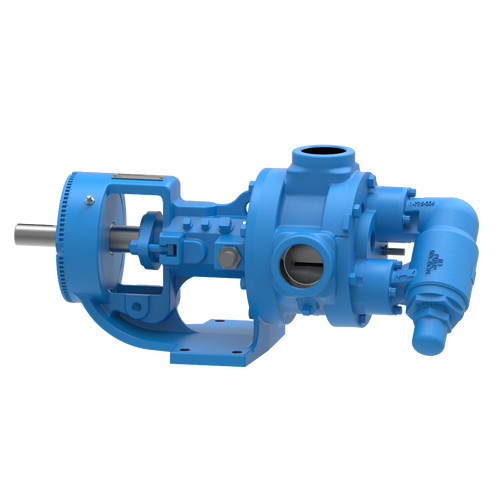

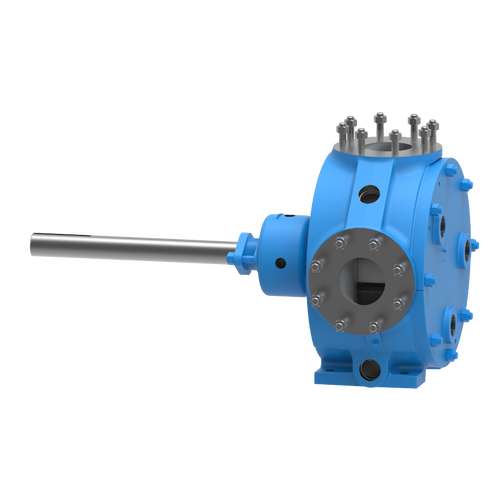

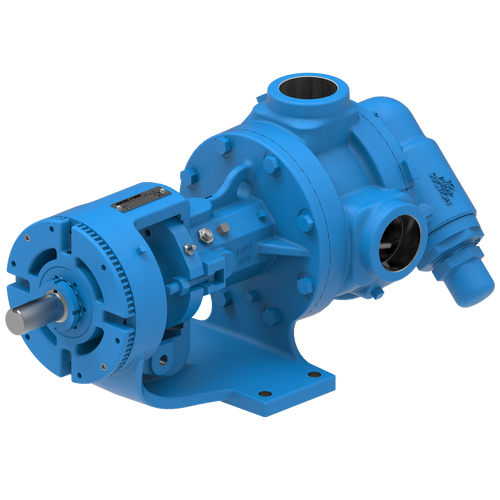

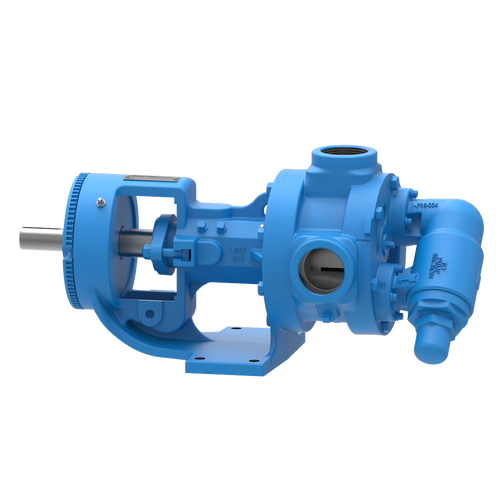

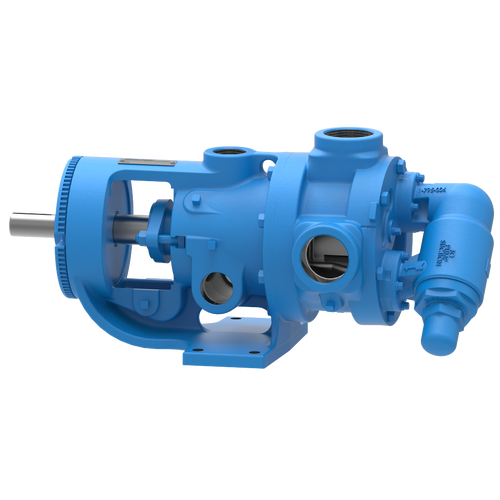

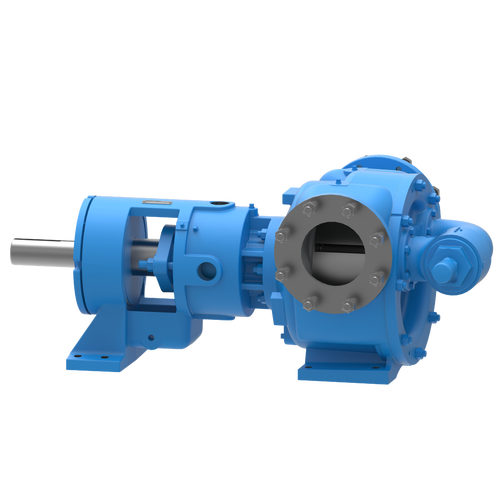

The 324A Series™ internal gear pump is the ideal solution for any non-corrosive application like adhesives, asphalt, paints & inks, etc. It can handle flow rates between 500-1600 GPM (114 to 364 m³/h).

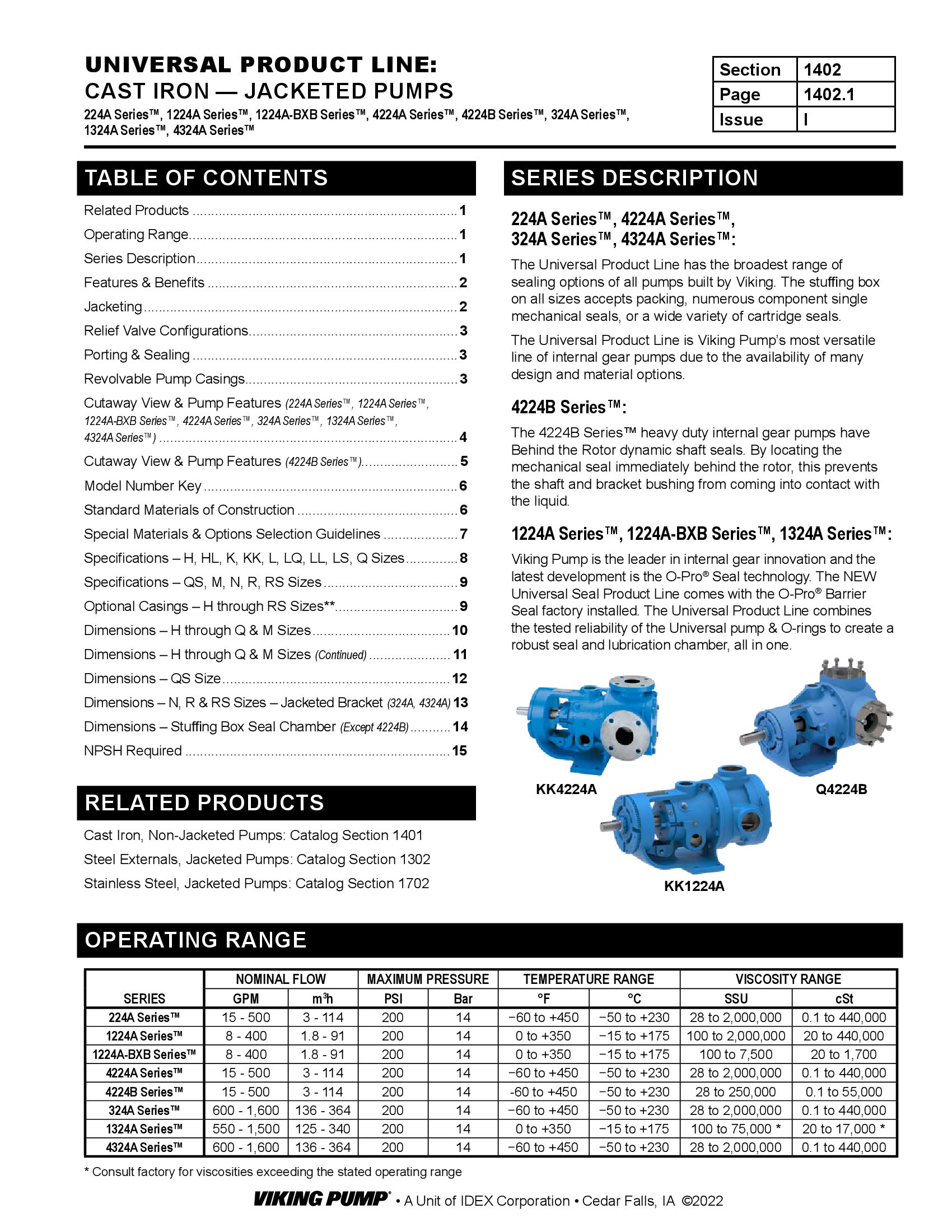

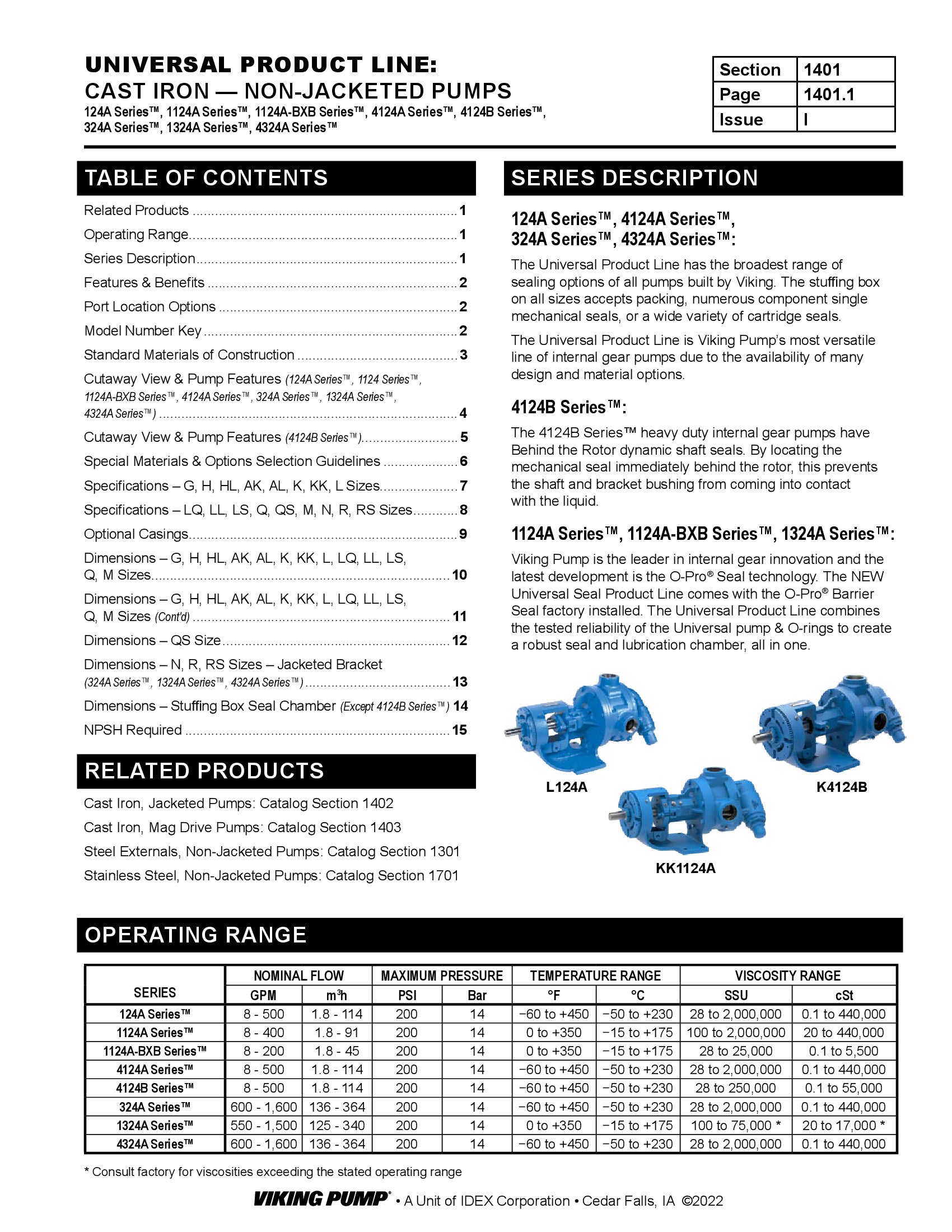

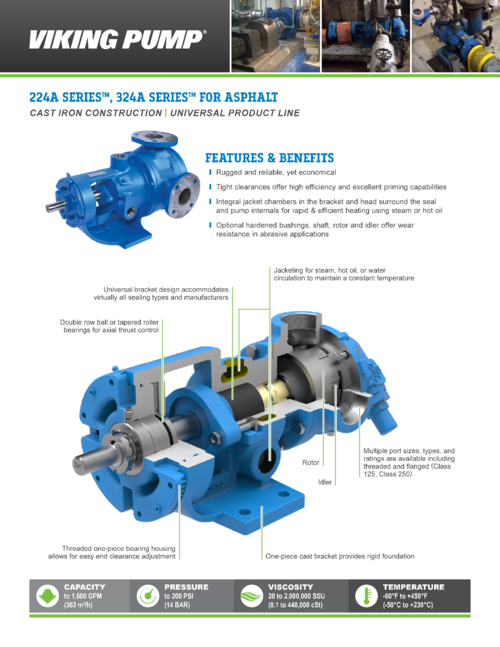

Features & Benefits

- Rugged and reliable, yet economical

- Widest range of sizes and options available to suit almost any non-corrosive application

- Tightest clearances for high efficiency and excellent priming capability

Capacity

500 to 1600 GPM

114 to 364 m³/h

Viscosity

28 to 2,000,000 SSU

1 to 440,000 cSt

Pressure

to 200 PSI

to 14 Bar

Temperature

-60 to +450 °F

-50 to +230 °C

Opcions

Porting

Drives

Mounting

Sealing

Specifications

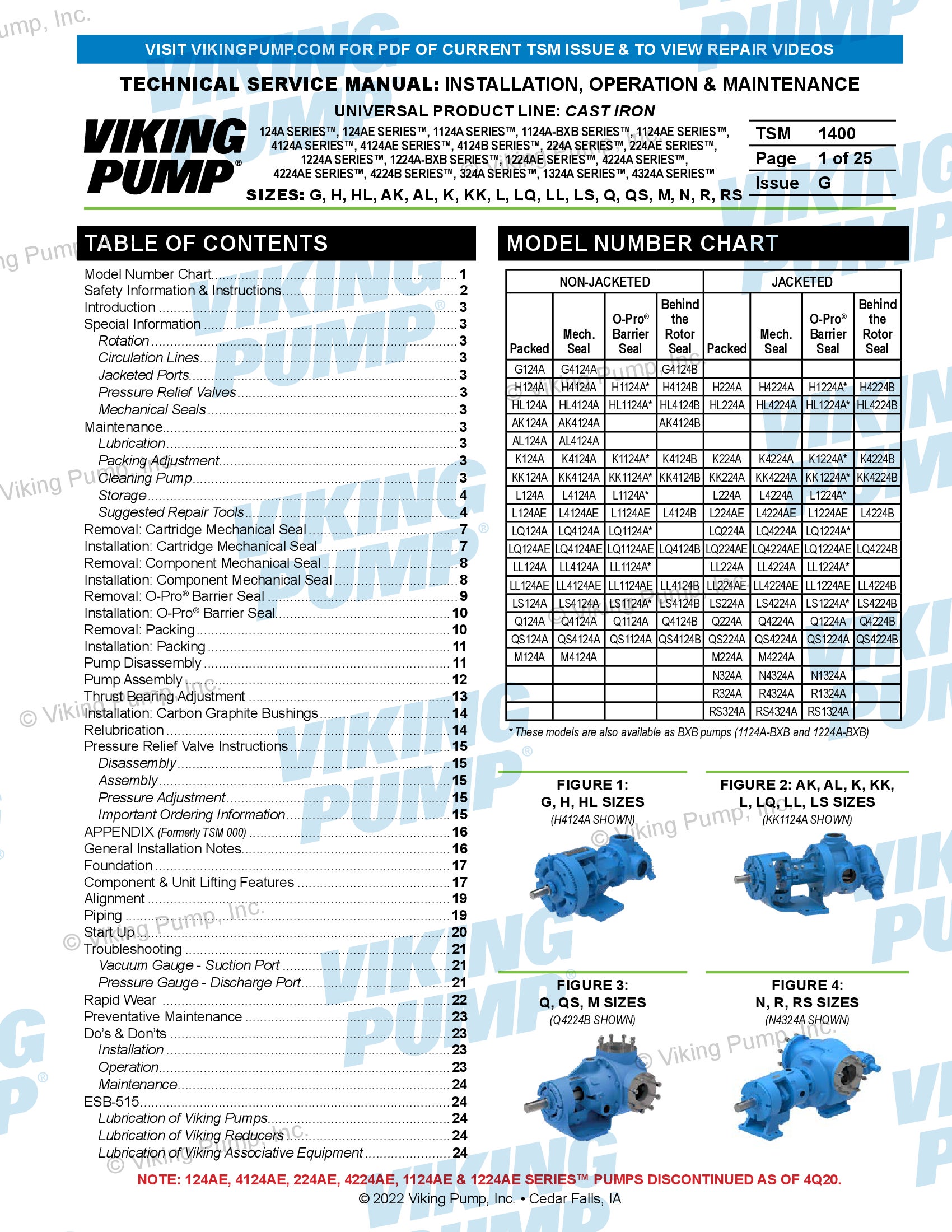

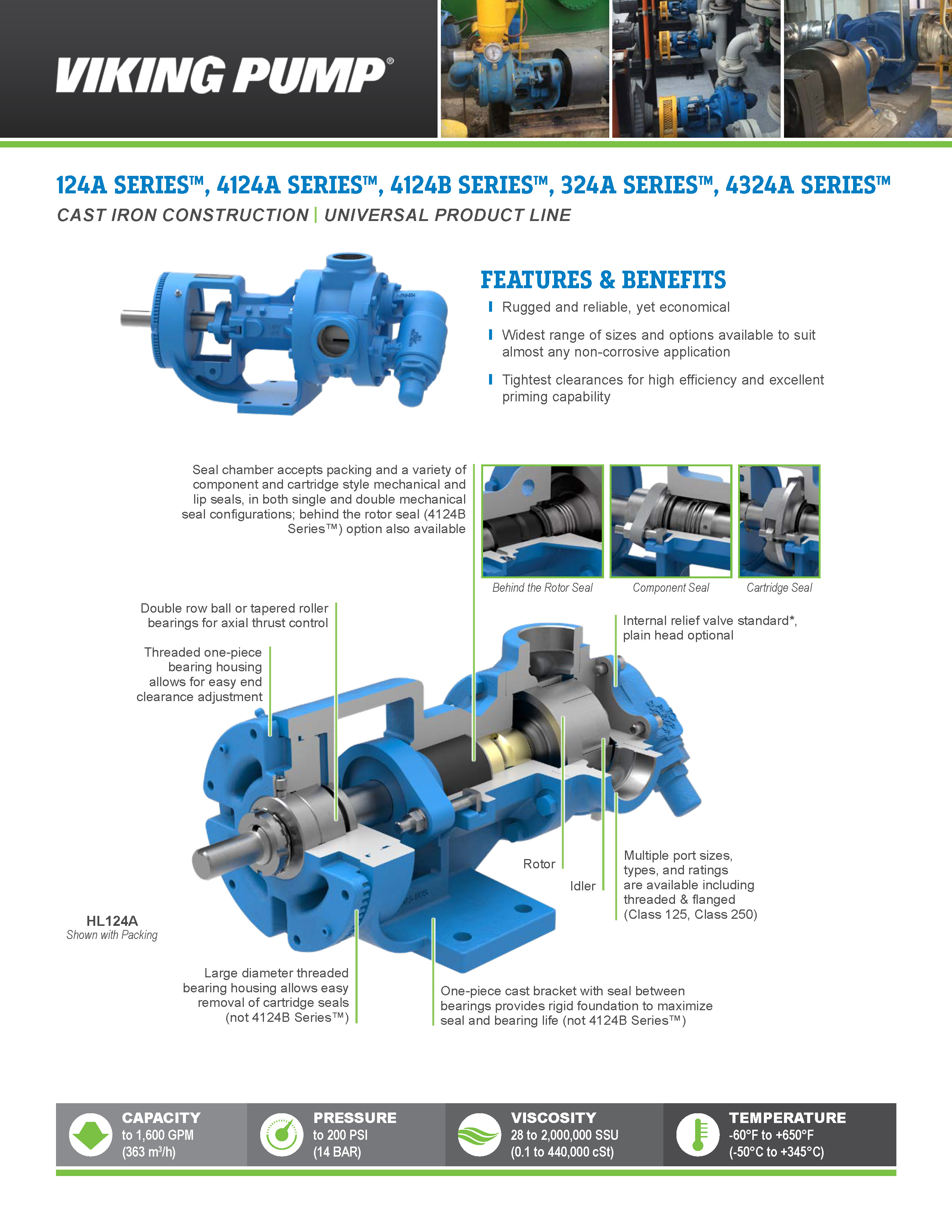

| Model | Standard Port Size | Nominal Pump Rating (GPM) | Nominal Pump Rating (m3/h) | Maximum RPM | Maximum Pressure PSI | Maximum Pressure BAR |

|---|---|---|---|---|---|---|

| N324A | 6 | 600 | 136 | 350 | 200 | 14 |

| R324A | 8 | 1100 | 250 | 280 | 200 | 14 |

| RS324A | 10 | 1600 | 364 | 280 | 125 | 9 |

Videos

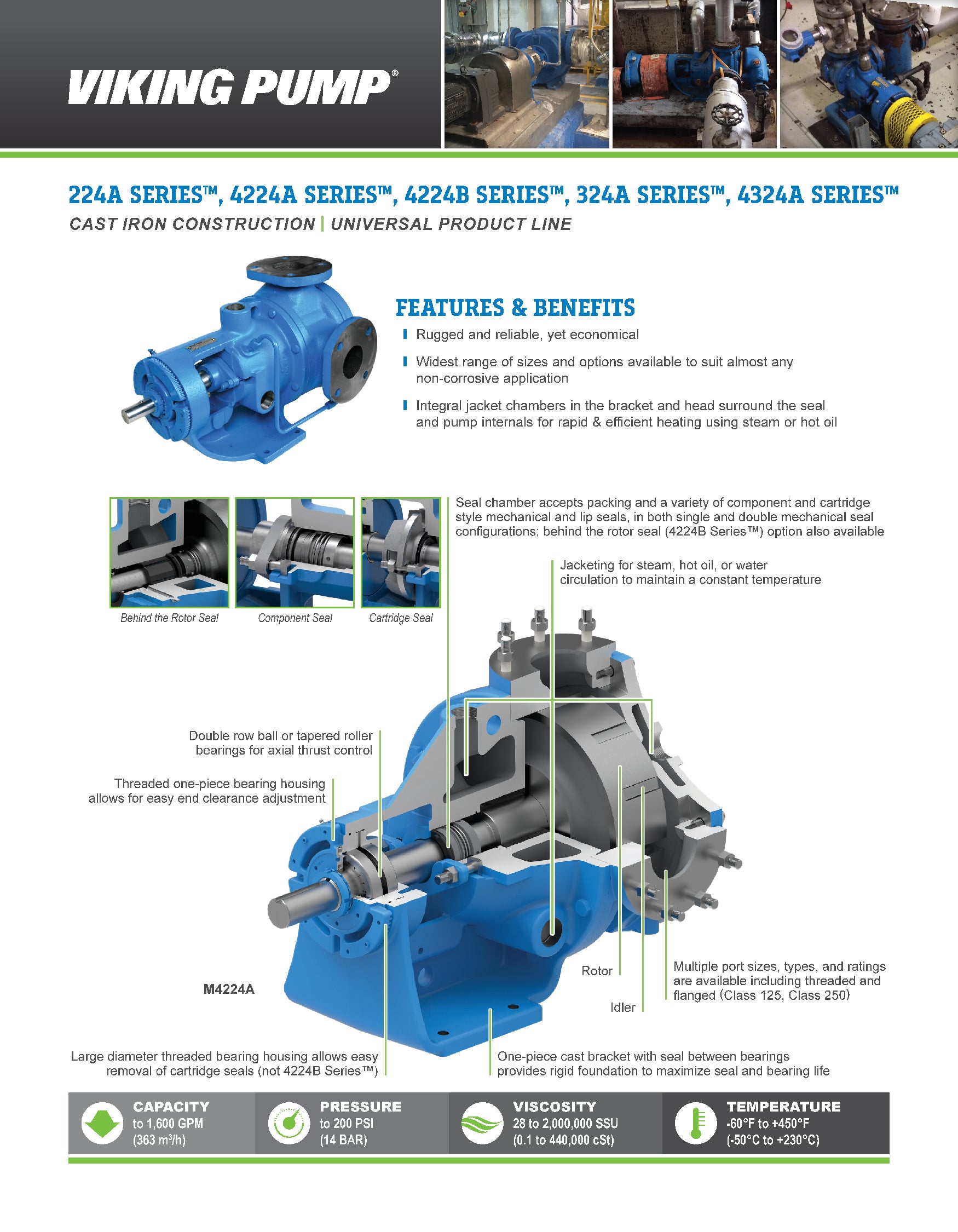

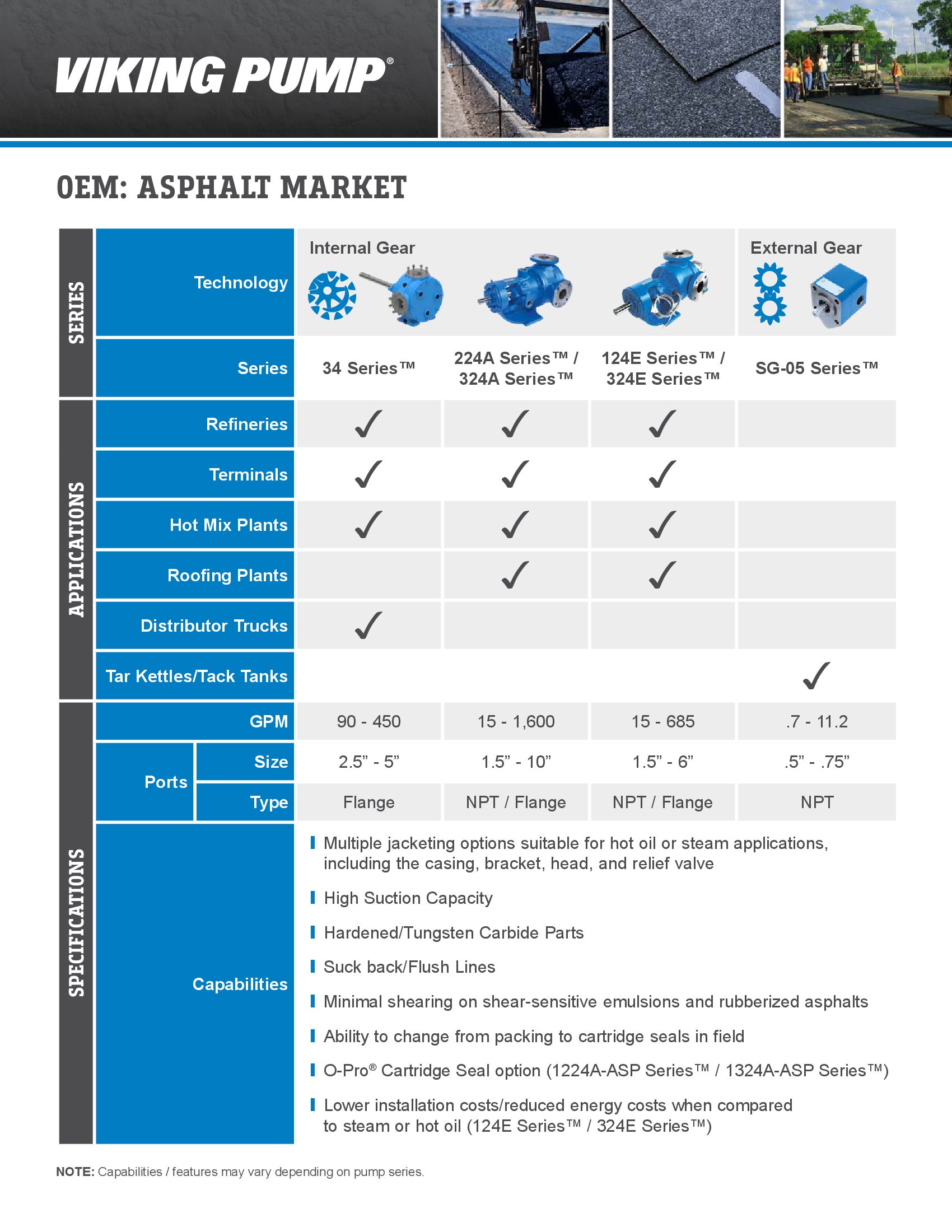

Filled Asphalt

Filled asphalts contain particulate used in the liquids’ end applications. Examples of this would be roofing materials and hot mix plants. Typically they are handled at elevated temperatures to reduce the viscosity of the asphalt mixture. The pump needs a source of heat like jacketing or electric heat to prevent the product from solidifying in the pump.

Asphalt Cement

Clean asphalt contains no fillers and is an oil based liquid. It is primarily used in paving roads, waterproofing liquids, and paints. Typically they are handled at elevated temperatures to reduce the viscosity of the asphalt. The pump needs a source of heat like jacketing or electric heat to prevent the product from solidifying in the pump.

Paints

Paints are shear sensitive liquids that can have a variety of solvents & pigment load concentrations that bring with them abrasive wear and chemical compatibility concerns.

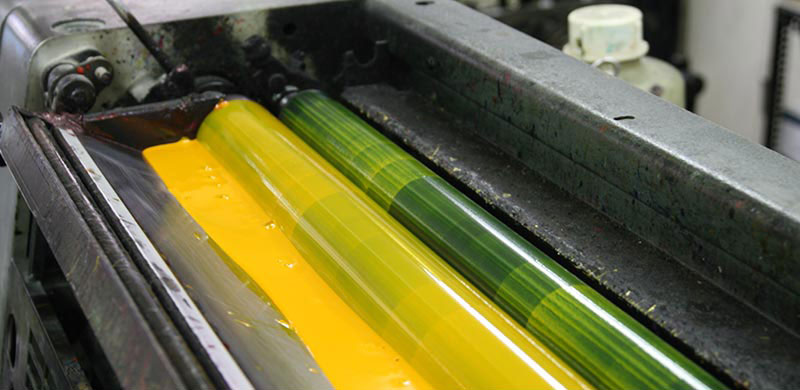

Inks

Inks for flexible packaging are shear sensitive liquids that can have a variety of solvents, waxes, surfactants, and semi-solid resin particles, and pigment load concentrations that bring with them abrasive wear and chemical compatibility concerns.

Resins

Resins are high viscosity liquids with potentially shear sensitive (thinning) components, and made up of solvents, waxes, surfactants, and semi-solid resin particles all with various chemical compatibility concerns. These resins can be used in polyurethanes, epoxies and other adhesives. In some cases, resins contain pigments that bring with them abrasive wear concerns.

Technical Service Manuals

Catalog Sections

Catalog Sections

Product Flyers

Product Flyers

-

DRAWINGS

N324A with Plain Head - 5" Class 125 ANSI RH PDF

STEP

N324A with Relief Valve - 6" Class 125 ANSI Opposite PDF

STEP

N324A with Jacketed Relief Valve - 6" Class 125 ANSI Opposite PDF

STEP

N324A with Plain Head - 6" Class 125 ANSI Opposite PDF

STEP

N324A with Jacketed Head - 6" Class 125 ANSI Opposite PDF

STEP

N324A with Plain Head - 5" Class 125 ANSI LH PDF

STEP

R324A with Jacketed Head - 8" Class 125 ANSI Opposite PDF

STEP

R324A with Relief Valve - 8" Class 125 ANSI Opposite PDF

STEP

R324A with Plain Head - 10" Class 125 ANSI Opposite PDF

RS324A with Jacketed Head - 10" Class 150 ANSI Opposite PDF