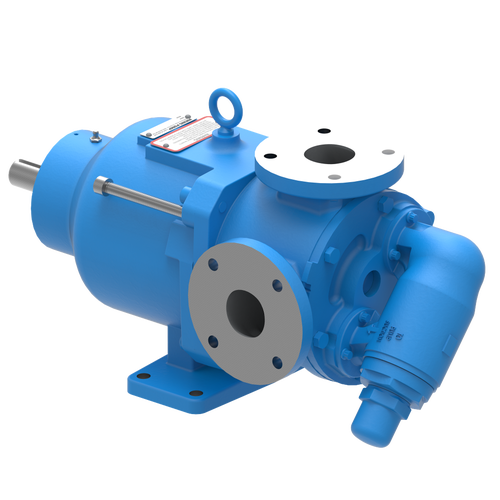

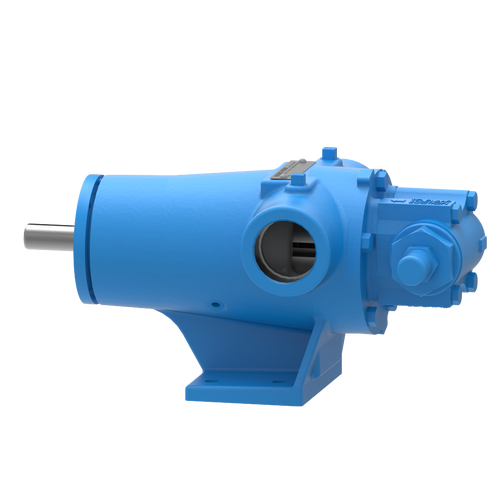

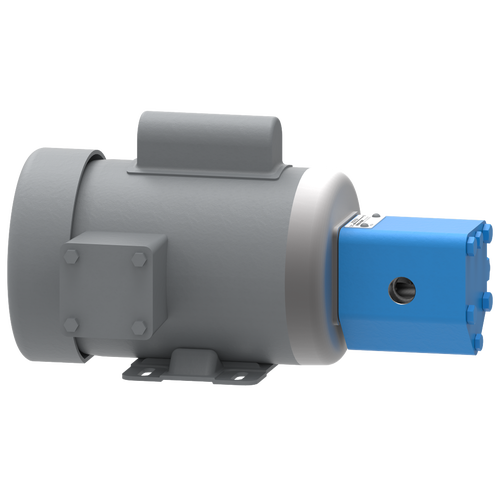

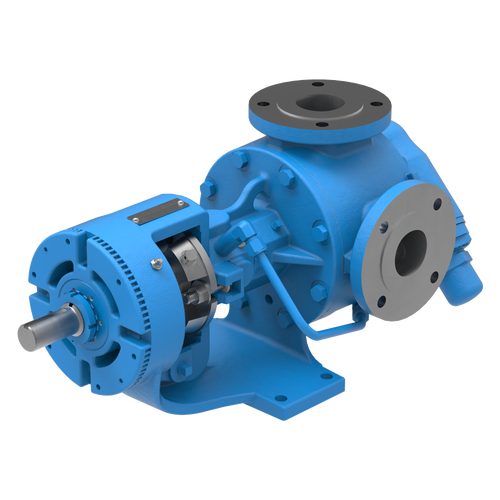

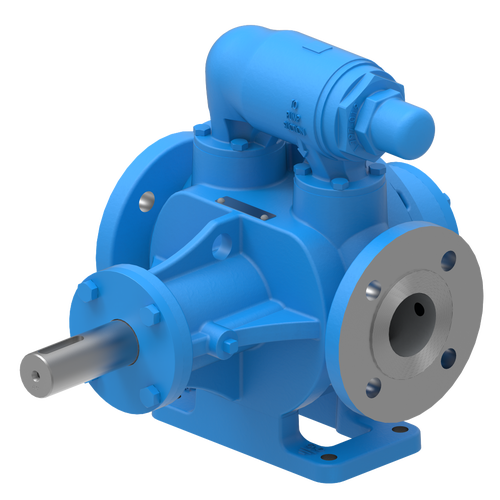

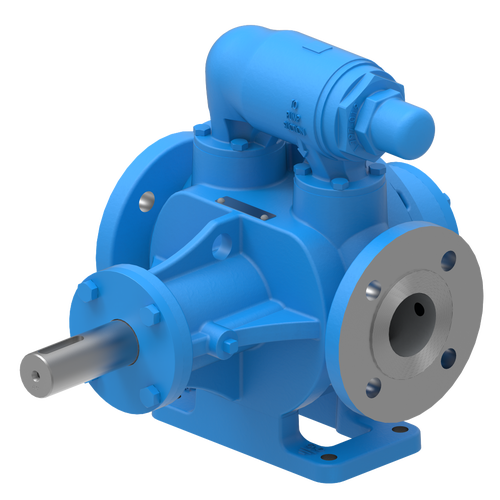

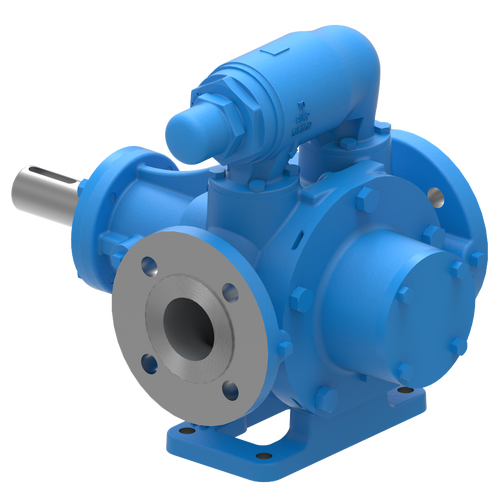

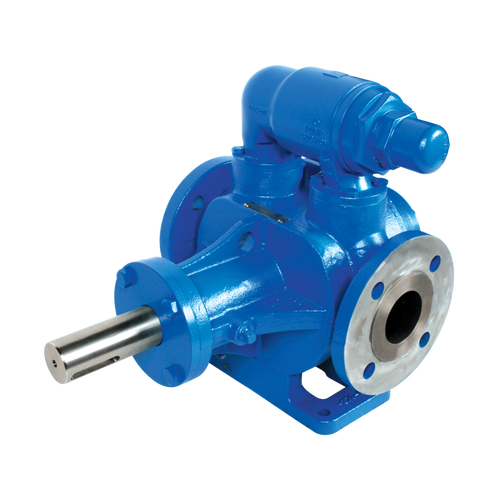

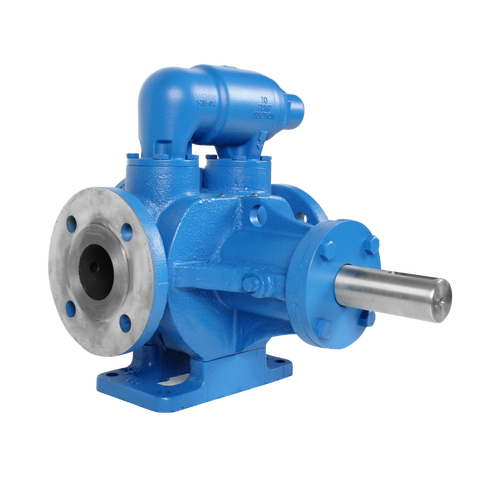

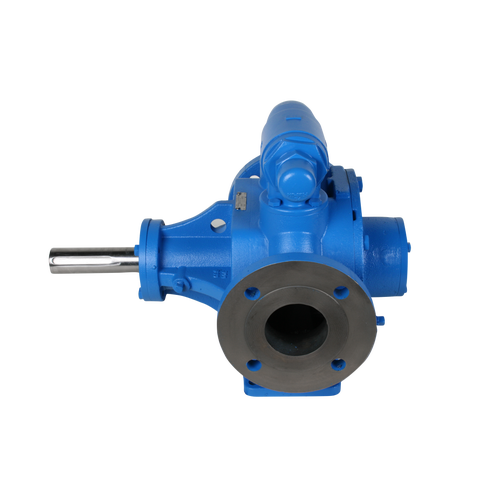

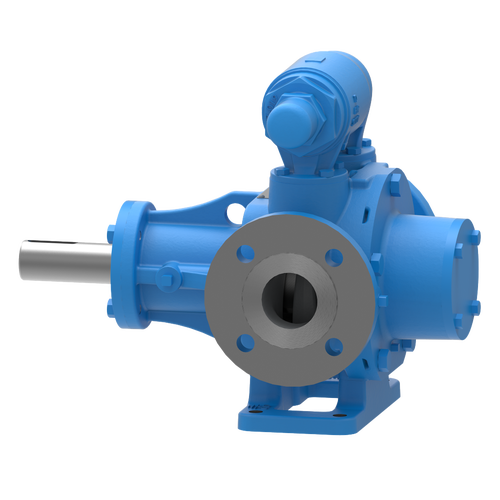

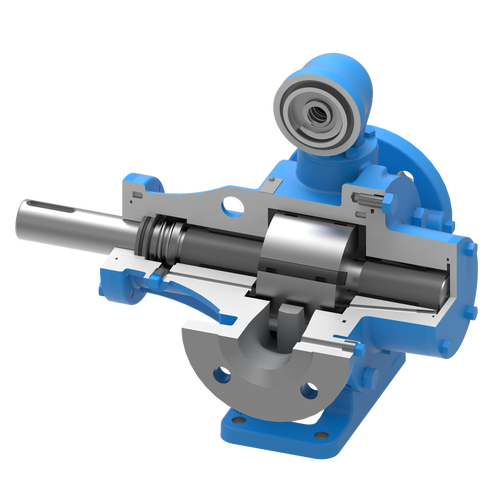

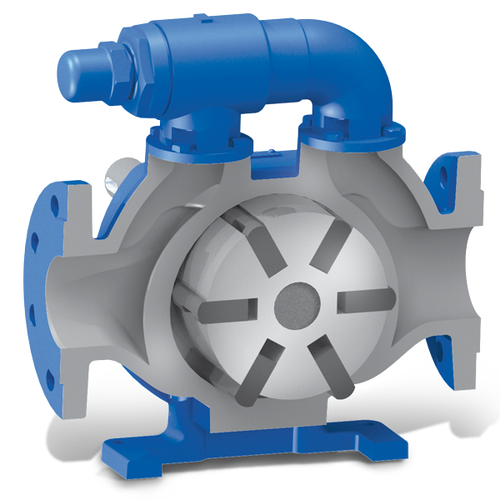

The LVP Series™ vane pump is the perfect solution for thin, corrosive industrial liquids, flammable liquids which require corrosion protection and applications where pressures or vacuum requirements exceed other pumps’ capabilities. It can handle flows up to 160 GPM (36 m³/h).

Features & Benefits

- Vane pump design offers ANSI or DIN flanges, and IEC or NEMA motor mounts to conform to international standards for enhanced application flexibility

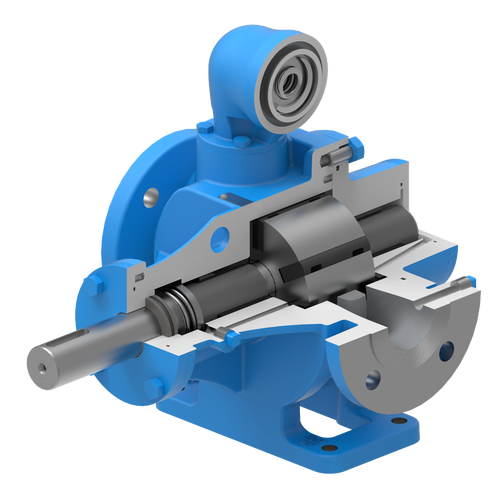

- High pressure and high efficiency with thin liquids

- 20 minute inline vane replacement reduces scheduled downtime

- Harder components than other vane pumps extend pump life

Capacity

to 160 GPM

to 36 m³/h

Viscosity

28 to 2,300 SSU

1 to 500 cSt

Pressure

to 200 PSI

to 14 Bar

Temperature

0 to +275 °F

-15 to +135 °C

Opcions

Porting

Drives

Mounting

Sealing

Specifications

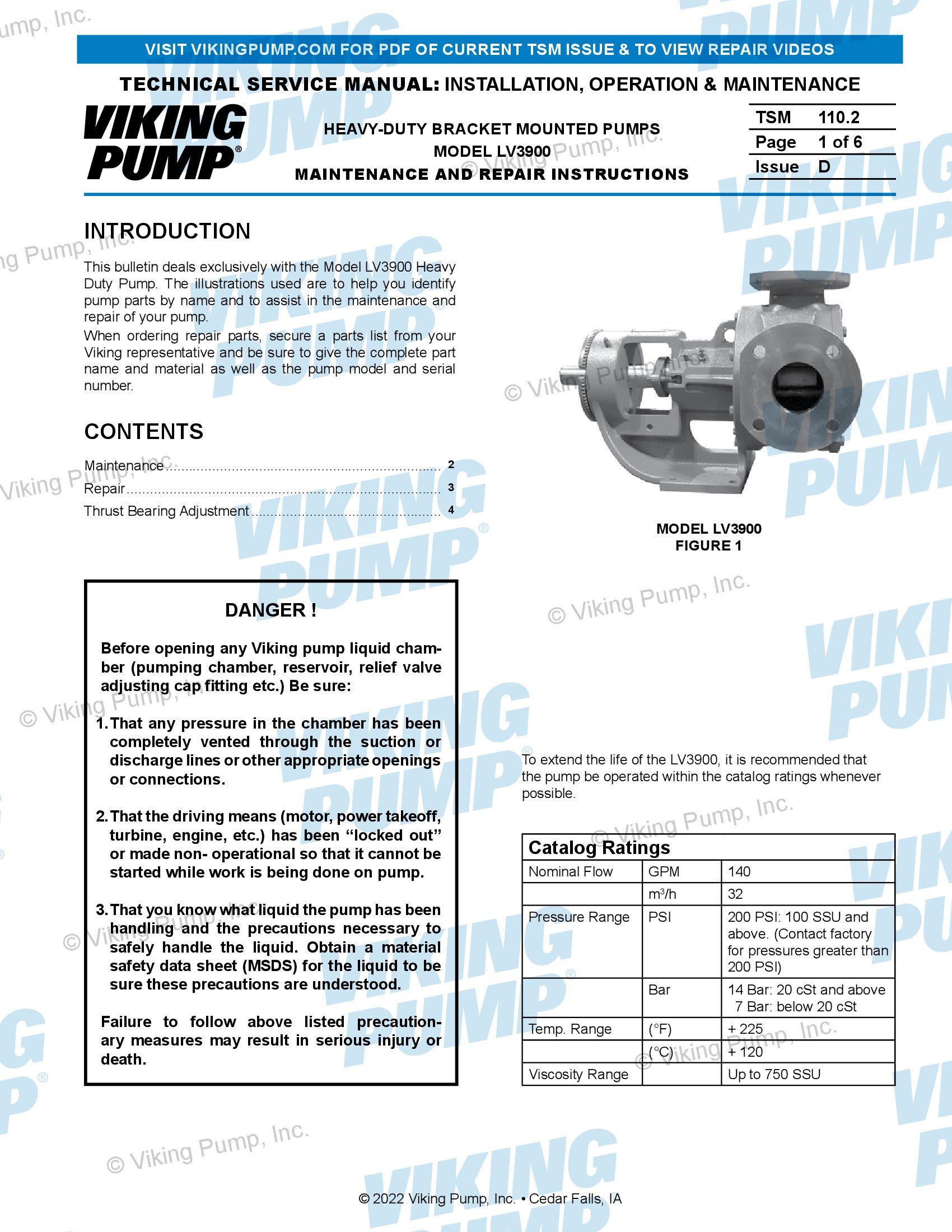

| Model | Standard Port Size IN /DIN FLANGE | Nominal Capacity at Maximum Rated Speed GPM (60hz) | Nominal Capacity at Maximum Rated Speed RPM (60hz) | Nominal Capacity at Maximum Rated Speed m3/hr (50hz) | Maximum RPM (50 hz) | Maximum Pressure PSI | Maximum Pressure BAR |

|---|---|---|---|---|---|---|---|

| LVP40017 | 1.5 / 40 | 20 | 1750 | 4 | 1450 | 200 | 14 |

| LVP41017 | 1.5 / 40 | 20 | 1750 | 4 | 1450 | 200 | 14 |

| LVP40027 | 1.5 / 40 | 40 | 1750 | 9 | 1450 | 200 | 14 |

| LVP41027 | 1.5 / 40 | 40 | 1750 | 9 | 1450 | 200 | 14 |

| LVP41057 | 2.0 / 50 | 80 | 1150 | 15 | 950 | 200 | 14 |

| LVP41087 | 2.0 / 50 | 100 | 950 | 23 | 950 | 200 | 14 |

| LVP41197 | 3.0 / 80 | 125 | 520 | 29 | 520 | 200 | 14 |

| LVP41237 | 3.0 / 80 | 160 | 520 | 36 | 520 | 200 | 14 |

Photos

Videos

Acids & Bases

Extremes on the ends of the pH scale that can result in severe corrosion and chemical attack of the pump body, gears, bushings, and elastomers. Pump construction will ultimately be driven by the specific liquid being handled and the construction that offers the greatest chemical resistance.

Alcohols

Chemical compatibility ranges greatly based on the alcohol and the subsidiary branch chains attached to it, resulting in potential chemical attack of the pump body, gears, bushings, and elastomers. Pump construction will ultimately be driven by the specific alcohol being handled and the construction that offers the greatest chemical resistance.

Solvents

The wide range of viscosity of various solvents plays a key role in determining the best pump for handling the application. Pump construction will ultimately be driven by the specific liquid being handled and the construction that offers the greatest chemical resistance and is the most viscosity appropriate.

Refined Fuels

Refined fuels would include petroleum based fuel oils and some Jet Fuels. Their viscosity and temperature handled can vary greatly. Normally these are handled in bulk transfer operations.

-

DRAWINGS

LVP40017U with Relief Valve - 1.5" Class 150 ANSI Oppsite PDF

LVP40027U with Relief Valve - 1.5" Class 150 ANSI Oppsite PDF

LVP40017M with Relief Valve - DIN 40 PN25 Opposite PDF

LVP40027M with Relief Valve - DIN 40 PN25 Opposite PDF

LVP41017M with Relief Valve - DIN 40 PN25 Opposite PDF

LVP41027M with Relief Valve - DIN 40 PN25 Opposite PDF

LVP41057M with Relief Valve - DIN 50 PN25 Opposite PDF

LVP41087M with Relief Valve - DIN 50 PN25 Opposite PDF

LVP41197M with Relief Valve - DIN 80 PN25 Opposite PDF

LVP41237M with Relief Valve - DIN 80 PN25 Opposite PDF

LVP41017U with Relief Valve - 1.5" Class 150 ANSI Oppsite PDF

LVP41027U with Relief Valve - 1.5" Class 150 ANSI Oppsite PDF

LVP41057U with Relief Valve - 2" Class 150 ANSI Oppsite PDF

LVP41087U with Relief Valve - 2" Class 150 ANSI Oppsite PDF

LVP41197U with Relief Valve - 3" Class 150 ANSI Oppsite PDF

LVP41237U with Relief Valve - 3" Class 150 ANSI Oppsite PDF