Emulsions are asphalt suspended in a mixture with water or other liquids. This is done to ease the application of the asphalt. Uses would be crack filling, coating roadways, or waterproofing. These emulsions can be shear sensitive and must be handled with care.

Runs longer

Prevents leaks

Protects the environment

Asphalt Emulsions Applications

- Emulsion plants

- Asphalt cement

- Soaps

- Foam asphalt

- Chemical additives

- Slurry seals

- Truck mounted sprayers

Fewer Leaks

Leaking asphalt has been the norm for decades.

We asked: "Why?"

Viking Pump's innovated O-Pro® seal technology prevents leaks before it creates a mess. This means you save on clean-up costs and prevent hazardous materials from coming into contact with your employees.

Replace Packing or Mechanical Seals with O-Pro®

Each O-Pro® Seal design option replaces packing or a mechanical seal by occupying the internal bracket cavity with a machined seal gland. Utilizing O-rings to seal externally on the bracket and internally on the shaft, a combination of O-rings and lubricating grease provide a robust seal. This prevents process fluids from leaking out of the pump. Learn more>>

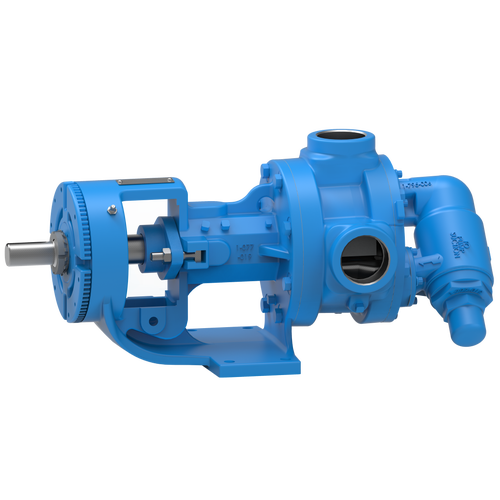

Viking in the Process

Whether it is loading, unloading, transferring, recirculating or blending, Viking Pump has the right design for your terminal application. Viking offers several pump constructions for asphalt that are tailored to meet your application requirements. Terminals and emulsion plants offer multiple pumping challenges, which Viking can help you solve. For example, Viking’s 1224A-ASP Series™ combines our proven robust design with our O-Pro® Cartridge seal, which prevents leakage and the emissions of harmful volatile chemicals into the environment. Now customers can operate a safe and eco-friendly facility.

Why Positive Displacement Pumps for Asphalt Applications?

Positive displacement pumps are used for asphalt because they provide a smooth, steady flow of product compared to other types of pumps which can produce pressure fluctuations. They are also capable of producing high discharge pressures. Additionally, they are easy to maintain and provide a greater degree of accuracy in terms of the volume of product delivered.