Cooking Oils

Cooking Oils

Custom Content One

Cooking oils are derived from oilseeds and include soybean oil, olive oil, canola (rapeseed) oil, peanut oil, sunflower oil and cottonseed oil, to name but a few. They are used for deep fat frying of vegetables and meats, as well as feedstocks for biofuels, oleochemicals and soaps and detergents. The viscosity is extremely temperature dependent, with some oils solidifying at room temperatures, but typically water-thin at higher temperatures.

Positive displacement pumps are ideal for manufacturing cooking oils because they can handle viscous fluids, provide a consistent and controlled flow rate, and maintain product integrity without causing shear or damage. These pumps are efficient at transferring oils across various stages of production, ensuring precise flow control and minimizing waste. Additionally, they can handle high-pressure applications and are capable of pumping oils with solid particles or varying viscosities, which is essential in the processing of different types of cooking oils.

Custom Content One

Viking in the Process

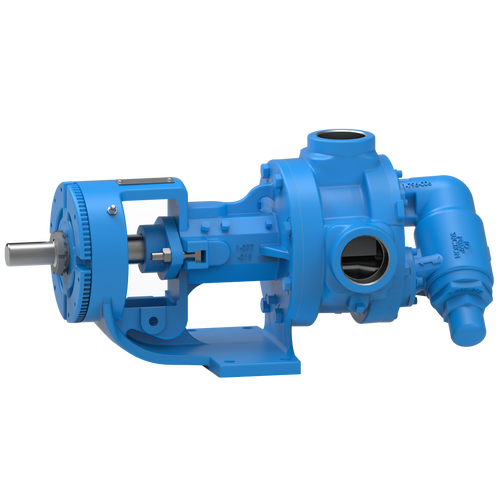

Viking cast iron internal gear pumps are used for oilseed processing, including transfer from press to filtration as well as solvent extraction processes, along with deodorization, storage and packaging. They are used for downstream applications including tank and railcar unloading, biodiesel and oleochemical processing and soap and detergent manufacturing. Jacketed models may be required for oils that solidify at ambient temperatures. Hygienic designs are typically not required because oils do not support bacterial growth. They are also used in hot oil applications on large industrial food fryers such as in potato chip manufacturing where they recirculate hot oil through filtration.

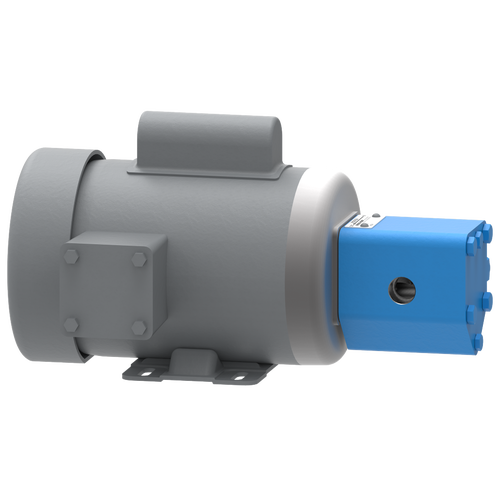

Viking external gear pumps, due to their lower flow rates, are used in restaurant hot oil fryers to recirculate and filter the hot oil.

Custom Content Two

Applications

- Oilseed processing

- Tank and Railcar loading and unloading

- Fryer filtration/recirculation

Recommended Pumps

-

SG SERIES™

- Ductile Iron

- Mechanical Seal

- up to 190 gpm | up to 43 m3h

-

4124A SERIES™

- Cast Iron

- Mechanical Seal

- up to 500 gpm | up to 114 m3h

-

4127C Series™

- Stainless Steel

- Mechanical Seal

- up to 320 gpm | up to 73 m3h

Articles / Case Studies

At Viking Pump, innovation is at the forefront of what we do. With the introduction of the U-Plus™ Bracket and ProPort™ Casing, we are redefining the capabilities of our internal gear pumps. These advancements are not just about new technology; they are about providing flexibility and efficiency in your pumping process. Let’s dive into what makes these innovations stand out.

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

Videos

- How Pump Packing Works - AnimationIn this video, learn about pump packing and how it works.March 14, 2025

- Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025