Local blending plants take bulk petroleum or synthetic base oils from refineries and mix them together with additives to create unique oil blends for specific applications and customers.

Typical Applications

- Base oils

- Antioxidants

- Corrosion inhibitors

- Detergents

- Viscosity index improvers

- Anti-foaming agents

- Extreme pressure additives

- Anti-wear agents

VIKING IN YOUR PROCESS

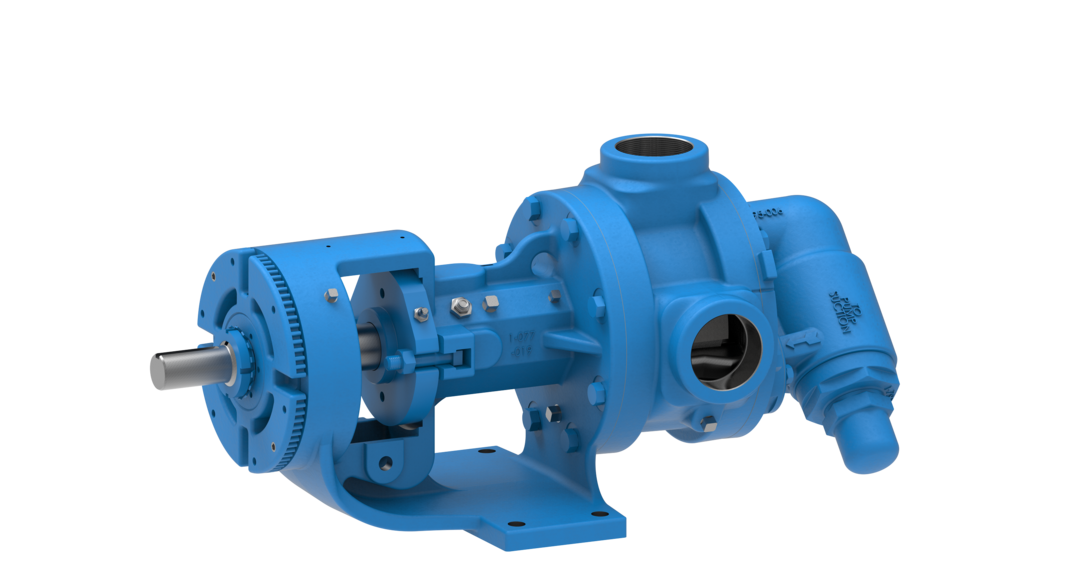

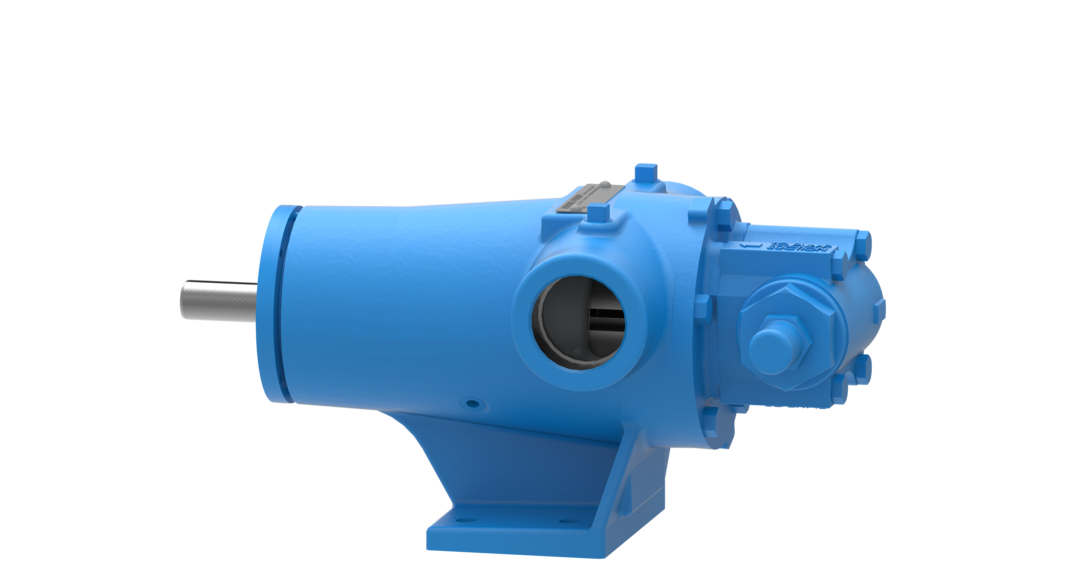

At lubricant blending plants, Viking pumps are used to unload railcars to talk farm, transfer from tank farm to day tank, and to meter additives into the base oil. They are frequently used to provide continuous tank recirculation to limit stratification, often with eductors on the discharge piping to improve in-tank mixing. And they transfer the finished product to packaging lines or to loading racks for bulk delivery.

Viking provides reliable transfer regardless of temperature-related changes in viscosity

Get a quote!

Whether you have a question or are ready to get a quote, let us know and we'll be in touch with you soon.

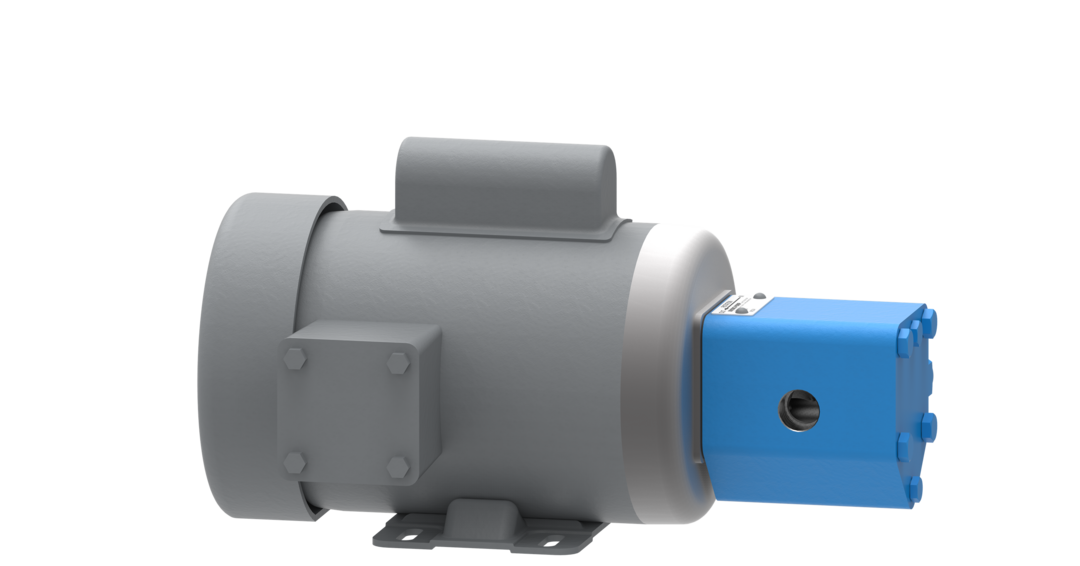

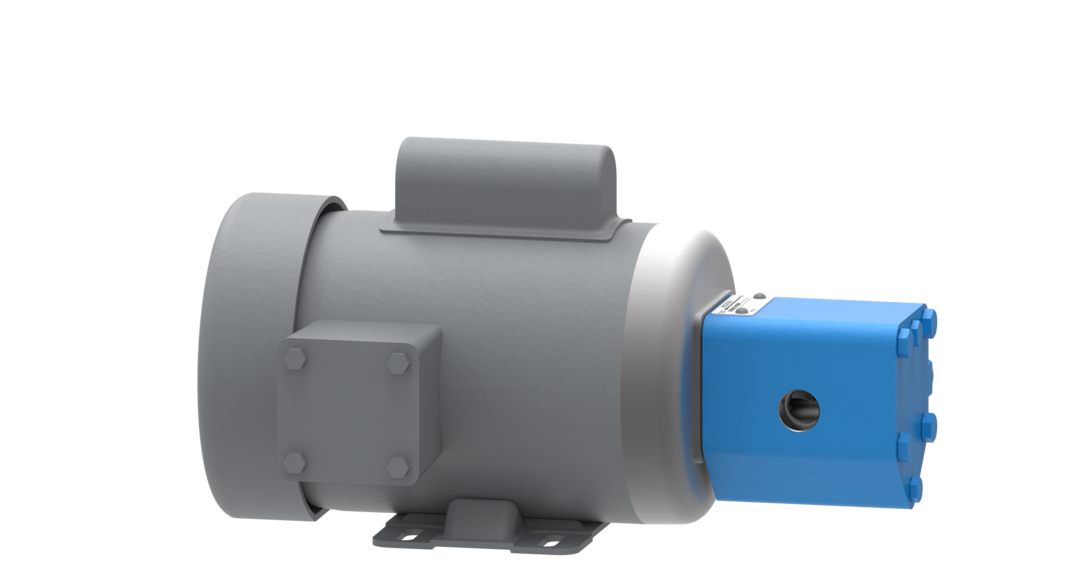

Replace Packing or Mechanical Seals with O-Pro®

Each O-Pro® Seal design option replaces packing or a mechanical seal by occupying the internal bracket cavity with a machined seal gland. Utilizing O-rings to seal externally on the bracket and internally on the shaft, a combination of O-rings and lubricating grease provide a robust seal. This prevents process fluids from leaking out of the pump. Learn more>>

Machinery lubrication pumps are used in everything from small backup generators to naval ships. Lube oils, as the name implies, are the liquids used to lubricate rotating and reciprocating machinery. Lube oils may be handled at higher pressures to ensure their penetration of the equipment

Typical Applications

- Dedicated lube oil filtration

- Cooling and/or dehydration for compressors, engines, turbines, and gearboxes

- Portable filtration systems

- API 614 lubrication systems

VIKING IN YOUR PROCESS

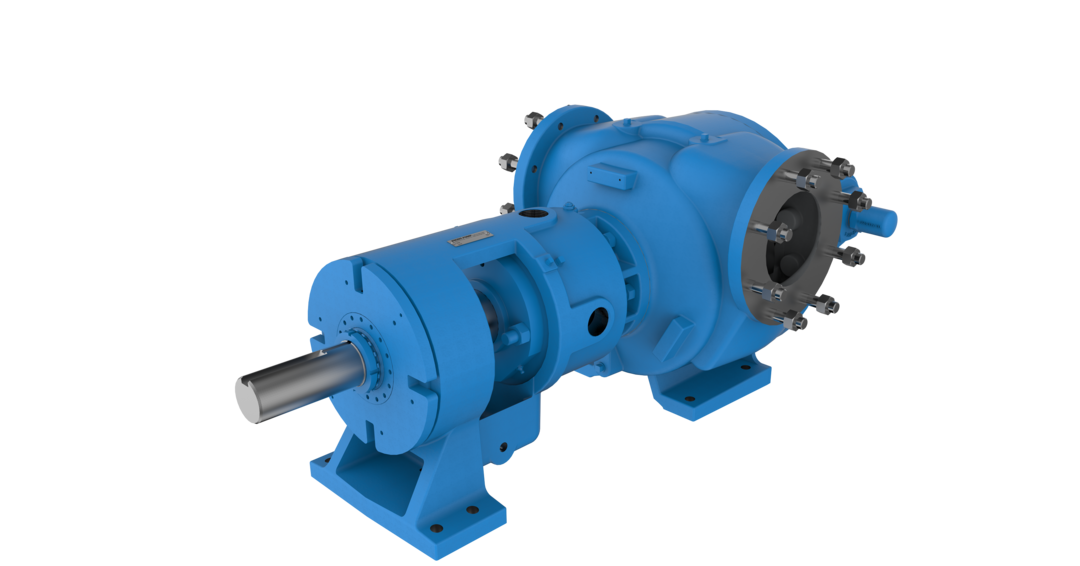

Viking pumps are used to scavenge (draw lubricant oil from a sump) and pump the oil through filters, heat exchangers and/or dehydration systems in full-flow or kidney-loop processes to remove contaminants, reduce temperature and remove free water, then return and spray it on key friction points within the machine. This ensures maximum lubrication effectiveness and longest life for the lubricated equipment.

Viking provides OEM lube pumps to many major manufacturers of refrigeration compressors, gas compressors, gas turbines, diesel engines and large gearboxes and transmissions. We also provide aftermarket pumps for many brands of equipment whose OEM pumps are problematic or are difficult to obtain replacements.

Get a quote!

Whether you have a question or are ready to get a quote, let us know and we'll be in touch with you soon.

THE VIKING PUMP ADVANTAGE

With over 110 years of experience providing positive displacement pumping solutions, Viking Pump has a rich, lengthy history of providing engineered solutions for tough applications like lube oils. Our dedicated sales and field support specialists are supported by a team of customer service representatives and engineers plus a knowledgeable team of application engineers are available to help with product selection and technical support. Click here to connect with our team.

Viking Pump's commitment to innovation and performance has made us a leader in the industry. Our extensive product line offers an array of solutions for corrugated box manufacturers, from our high-performance pumps to our advanced engineering capabilities. With a variety of custom designs available, Viking Pump can help you optimize your production process and increase your bottom line.