Butter

Hygienic positive displacement pumps are essential in the processing and transferring of butter due to their ability to handle viscous products safely and efficiently while maintaining the integrity and quality of the product. These pumps operate by trapping a fixed amount of butter and moving it through the pump with each rotation or cycle, ensuring a consistent flow without causing shear stress or altering the texture of the butter. Their design prioritizes sanitation and is often composed of stainless steel or other food-grade materials, minimizing contamination risks and adhering to strict hygiene standards required in food processing. Moreover, the gentle handling characteristic of positive displacement pumps prevents the butter from overheating, maintaining its natural properties and taste. This makes them an ideal choice in industries where maintaining product quality and safety is paramount.

Recommended Pumps

-

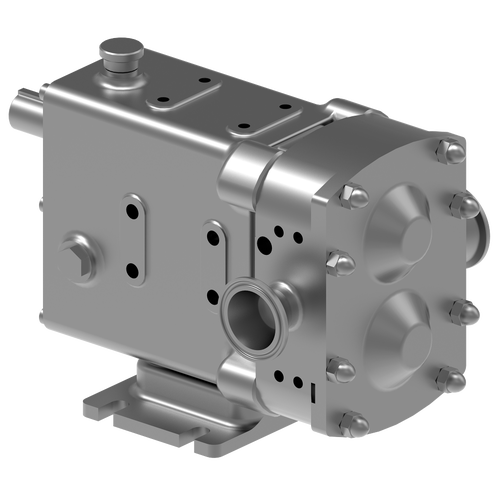

REVOLUTION® SERIES

- Stainless Steel

- |

-

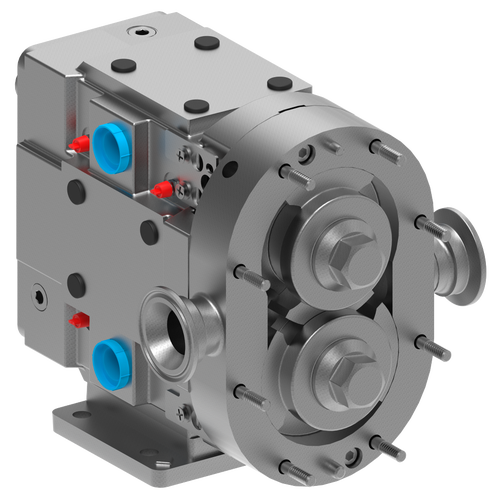

TRA®20 SERIES

- Stainless Steel

- Mechanical Seal

- 0-450 gpm | 0-102 m3h

-

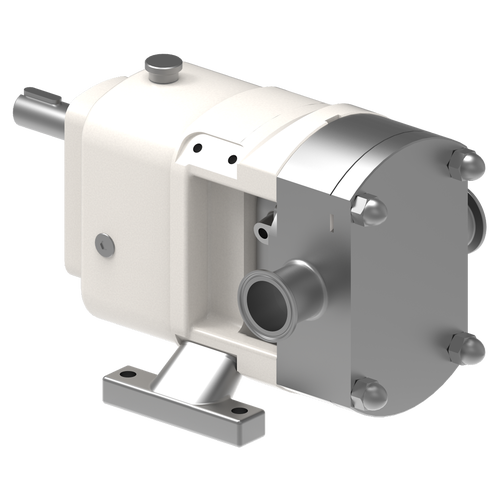

CLASSIC+ SERIES™ / MULTIPUMP® SERIES

- Stainless Steel

- Mechanical Seal

- 0-832 gpm | 0-189 m3h

- Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

- Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025