Typical Applications

- Bulk Transfer

- Blending

- Intermediate Transfer

- Metering

Meeting the Challenge of Low Viscosity Liquids

Liquids within the alcohol manufacturing process- like methanol, butyl alcohol, isopropyl alcohol, and more- have low viscosities which can make them difficult to pump. The thin consistency makes them likely to slip backwards in the process, leak through tiny gaps and crevices, wear away at parts, and ultimately reduce the efficiency and performance of the pump.

Viking Pump's answer to this challenge is precise clearances, utilizing materials engineered to handle low lubricity liquids, superior sealing options, and using chemical resistant 316 stainless steel.

Viking in the Process

Viking pumps are used in wide variety of different processes in the transfer, blending and metering of alcohols.

With methanol, Viking pumps are used for blending in production of formaldehyde, for automobile antifreeze, and for transfer as a general solvent.

Viking pumps in butyl alcohol applications are used for blending and transfer in the preparation of esters and butyl acetates, along with blending/metering as a solvent in resins and coatings.

With isopropyl alcohol, Viking pumps are used for blending and transfer in a large number of liquids, such as: deicing agents, perfumes, lacquers, pharmaceuticals, and resins.

Viking pumps are used to transfer ethyl alcohol that is used in the manufacture of fuels, disinfectants, solvents and other organic compounds.

Get a quote!

Whether you have a question or are ready to get a quote, let us know and we'll be in touch with you soon.

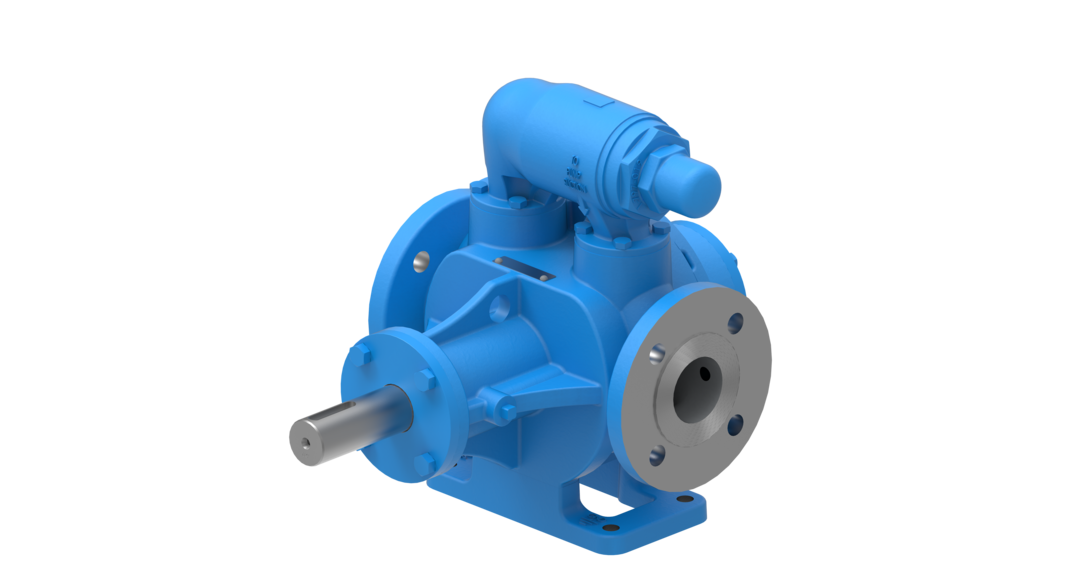

8127A SERIES™

| 316 Stainless Steel

| Sealless design

| Chemically resistant material options

| Capacities to 500 GPM

Video Resources

THE VIKING PUMP ADVANTAGE

With over 110 years of experience providing positive displacement pumping solutions, Viking Pump has a rich, lengthy history of providing engineered solutions for tough applications like alochol. Our dedicated sales and field support specialists are supported by a team of customer service representatives and engineers plus a knowledgeable team of application engineers are available to help with product selection and technical support. Click here to connect with our team.

Viking Pump's commitment to innovation and performance has made us a leader in the industry. Our extensive product line offers an array of solutions for corrugated box manufacturers, from our high-performance pumps to our advanced engineering capabilities. With a variety of custom designs available, Viking Pump can help you optimize your production process and increase your bottom line.