Biofuels are a renewable fuel that is produced from biomass and is typically blended with refined fuels to provide energy for transportation. The two most common biofuels are biodiesel and ethanol. Biodiesel is produced by combining alcohol with vegetable oil, animal fat, or recycled cooking grease. Ethanol is made from various plant materials through fermenting their starches, sugars, and cellulose components to produce alcohol.

Improve Operational Efficiency

We know the struggle:

- Thin liquids are difficult to transfer

- Corrosive materials wear your parts quickly

- Varying system back pressure interrupts flow

Whether unloading waste cooking oil, moving product through the esterification & transesterification process, or transferring glycerin byproduct in the production of biodiesel or pumping mash “slurry” during the processing of ethanol – Viking Pump’s robust & easy to maintain heavy duty pumps will improve your operational efficiency.

- Tight clearances expertly handling thin liquids like ethanol

- Stainless steel material protects from frequent stops for maintenance or replacement

- Gear pumps pump consistently and smoothly despite varying pressure

Typical Biofuel Applications

- Biodiesel

- Diesel Fuel

- Fatty Acid Methyl Esters (FAMEs)

- Wate cooking oil or animal fats

- Methanol

- Glycerin

- Sodium Hydroxide (caustic soda)

- Ethanol

- Gasoline

- Additives

- Mash "Slurry"

- Syrup

Viking in the Process

Viking biodiesel transfer pumps are used extensively in the production of biofuels.

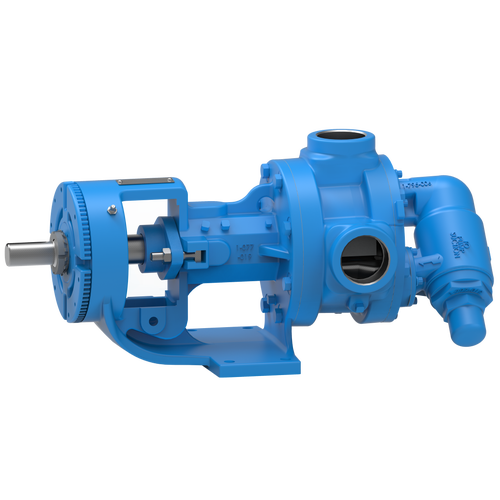

Cast iron internal gear pumps (4124A Series™) can handle viscosities from ethanol thin to thick slurry applications and are used where consistent flow rate is needed even with varying system back pressure such as when pumping through a filter or strainer.

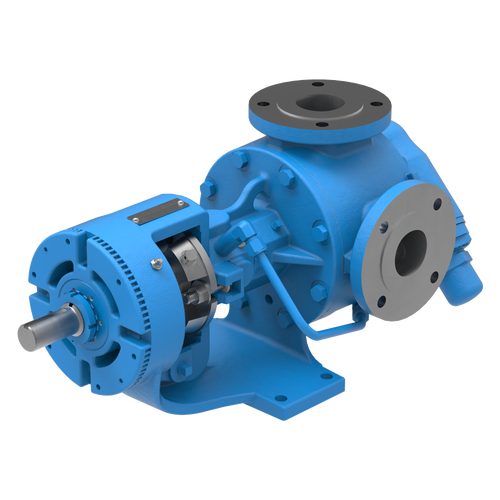

Stainless steel internal gear pumps (4127A Series™) are used for corrosive applications such as the transfer of the fatty acids used in the creation of biodiesel.

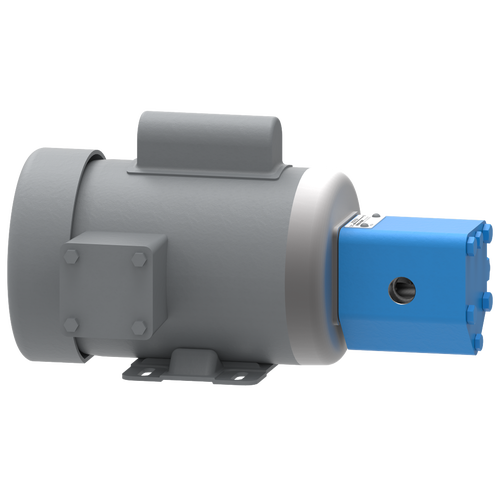

External gear pumps (SG Series™) are used for applications with lower flow rates or higher pressures such as blending in fuel oil additives. Whether unloading waste cooking oil, moving product through the esterification & transesterification process, or transferring glycerin byproduct in the production of biodiesel or pumping mash “slurry” during the processing of ethanol – Viking Pump’s robust & easy to maintain pumps will improve your operational efficiency.

What is Biodiesel?

Biodiesel is a renewable fuel produced from biomass that is most often blended with refined fuels to provide energy for transportation. It is made by combining alcohol with vegetable oil, animal fat, or recycled cooking grease. Biodiesel can be used in place of diesel fuel in any diesel engine and provides a cleaner-burning alternative that produces fewer emissions. Additionally, biodiesel is biodegradable.

How does Biodiesel work?

Biodiesel works in the same way as regular diesel fuel — it powers cars, trucks, boats, and other vehicles. The difference is that when biodiesel combusts in an engine it emits fewer pollutants into the environment than regular diesel. Additionally, biodiesel tends to produce fewer emissions overall than traditional diesel does because it takes less energy to produce.