Heading

ASPHALT CEMENT

Clean asphalt contains no fillers and is an oil based liquid. It is primarily used in paving roads and providing waterproofing for building materials. Typically they are handled at elevated temperatures to reduce the viscosity of the asphalt. The pump needs a source of heat like jacketing or electric heat to prevent the product from solidifying in the pump.

Heading

ASPHALT EMULSIONS

Emulsions are asphalt suspended in a mixture with water or other liquids. This is done to ease the application of the asphalt. Uses would be crack filling, coating roadways, or waterproofing. These emulsions can be shear sensitive and must be handled with care.

Heading

FILLED ASPHALT

Filled asphalts contain particulate and are used in the production of roofing materials. Hardened parts within the pump are required to resist abrasive wear. Typically they are handled at elevated temperatures to reduce the viscosity of the asphalt mixture. The pump needs a source of heat like jacketing or electric heat to prevent the product from solidifying in the pump.

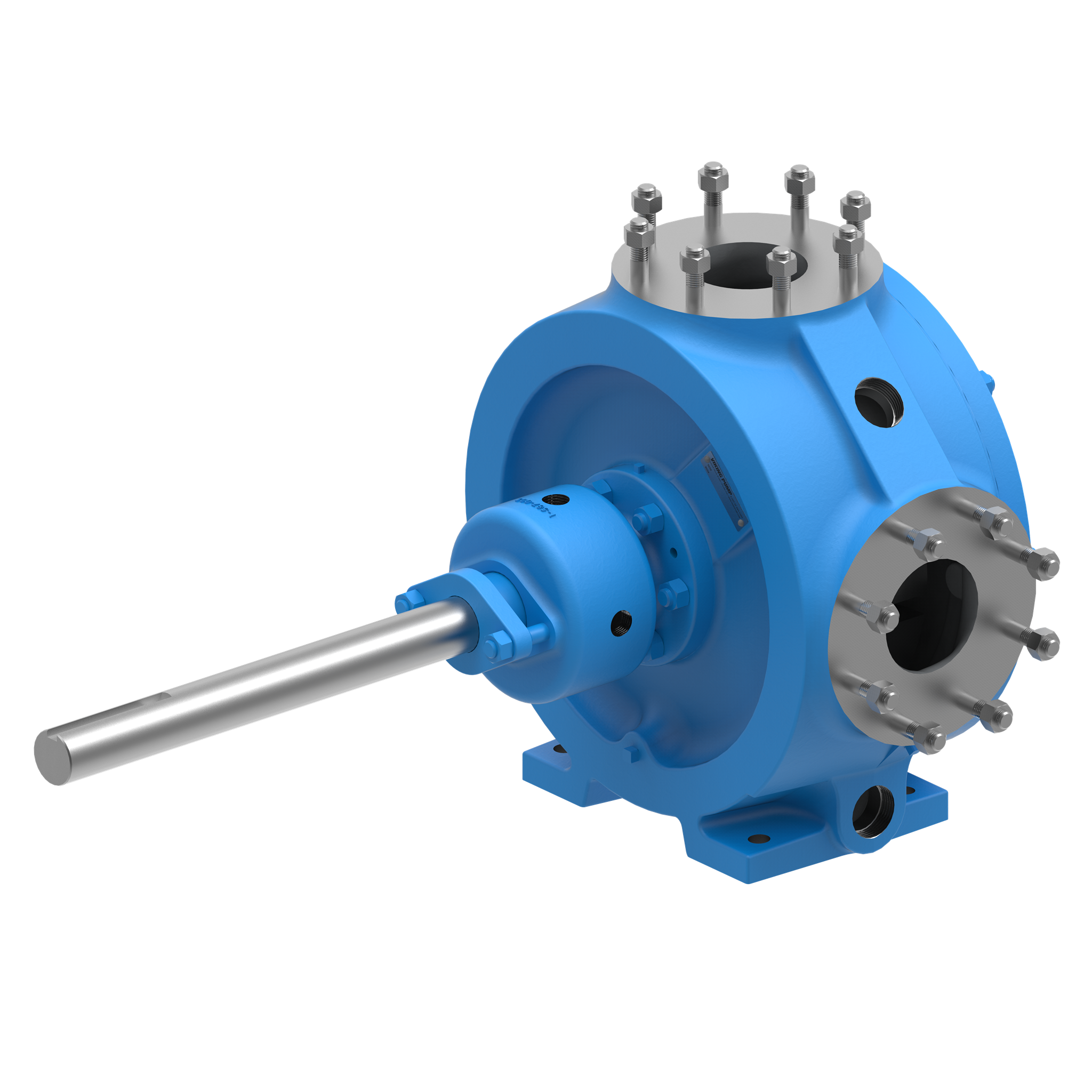

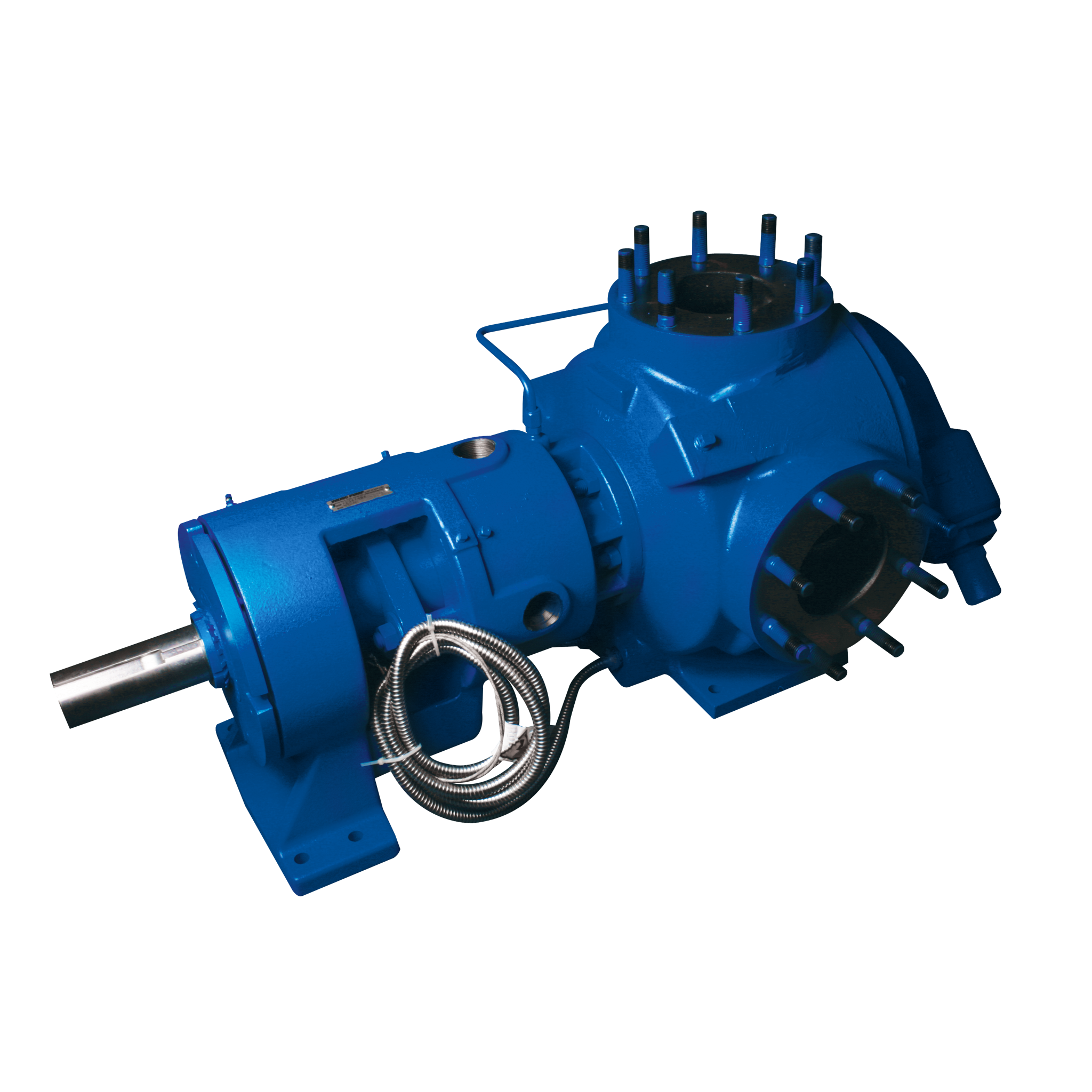

ASPHALT CEMENT PUMPS

Viking Pump Asphalt Cement Applications:

- Blending Terminals - PMA (polymer modified asphalt), cutback asphalt, coating (flux) for roofing plants, blown asphalt

- Intermodal Terminals

- Storage Terminals

- Hotmix Plants - Unloading, transferring, metering

VIKING IN THE PROCESS

Viking pumps play a vital role in reliably transferring asphalt for the pavement and building material markets including at hot mix plants, asphalt terminals, sealant plants, and roofing manufacturing facilities. Viking pumps are used for unloading trucks and railcars; transferring and metering asphalt to drum mixers at hot mix plants; pumping additives at asphalt terminals and sealant plants; and moving clean asphalt flux & blown asphalt at roofing plants. Viking Pump’s robust & easy to maintain pumps will improve your operational efficiency.

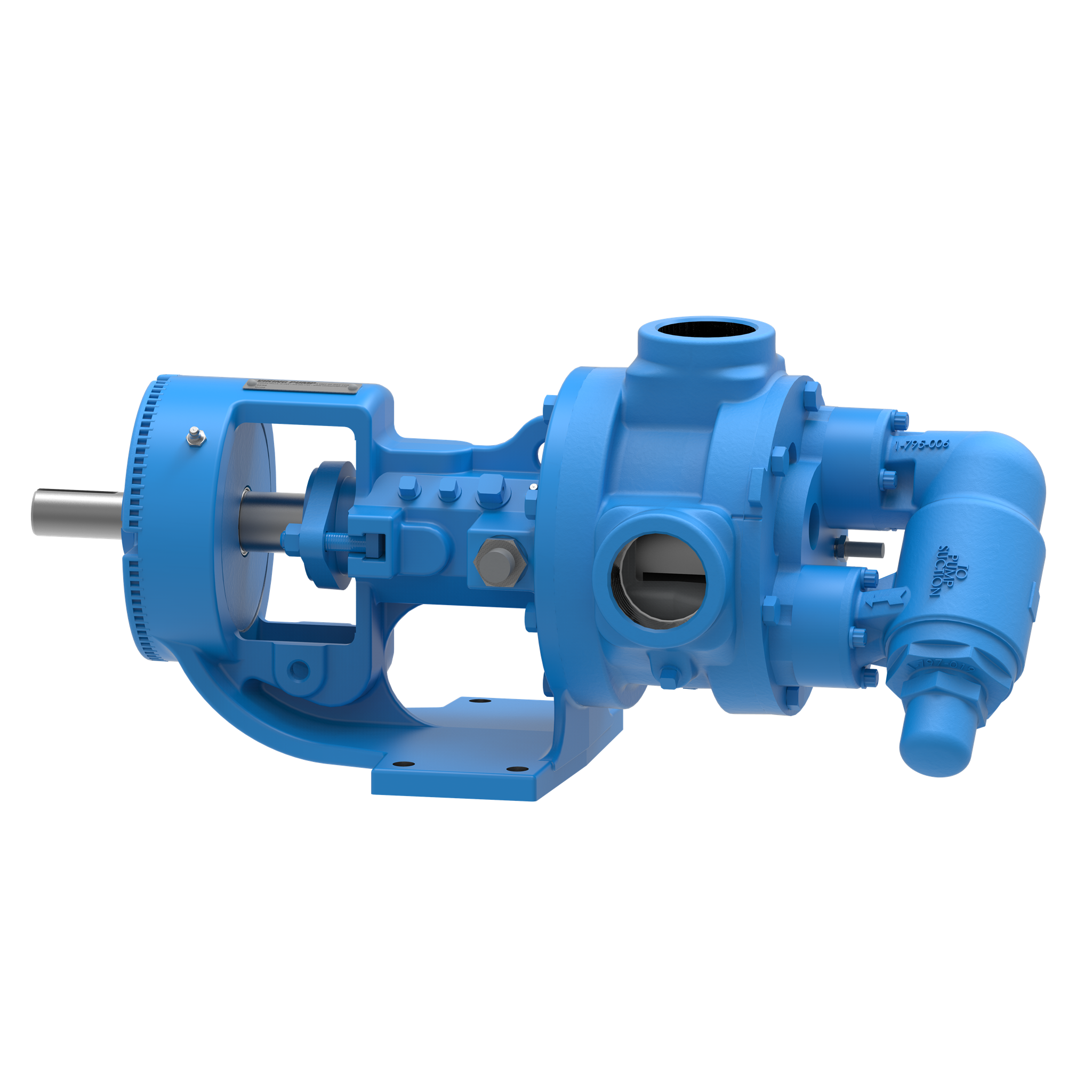

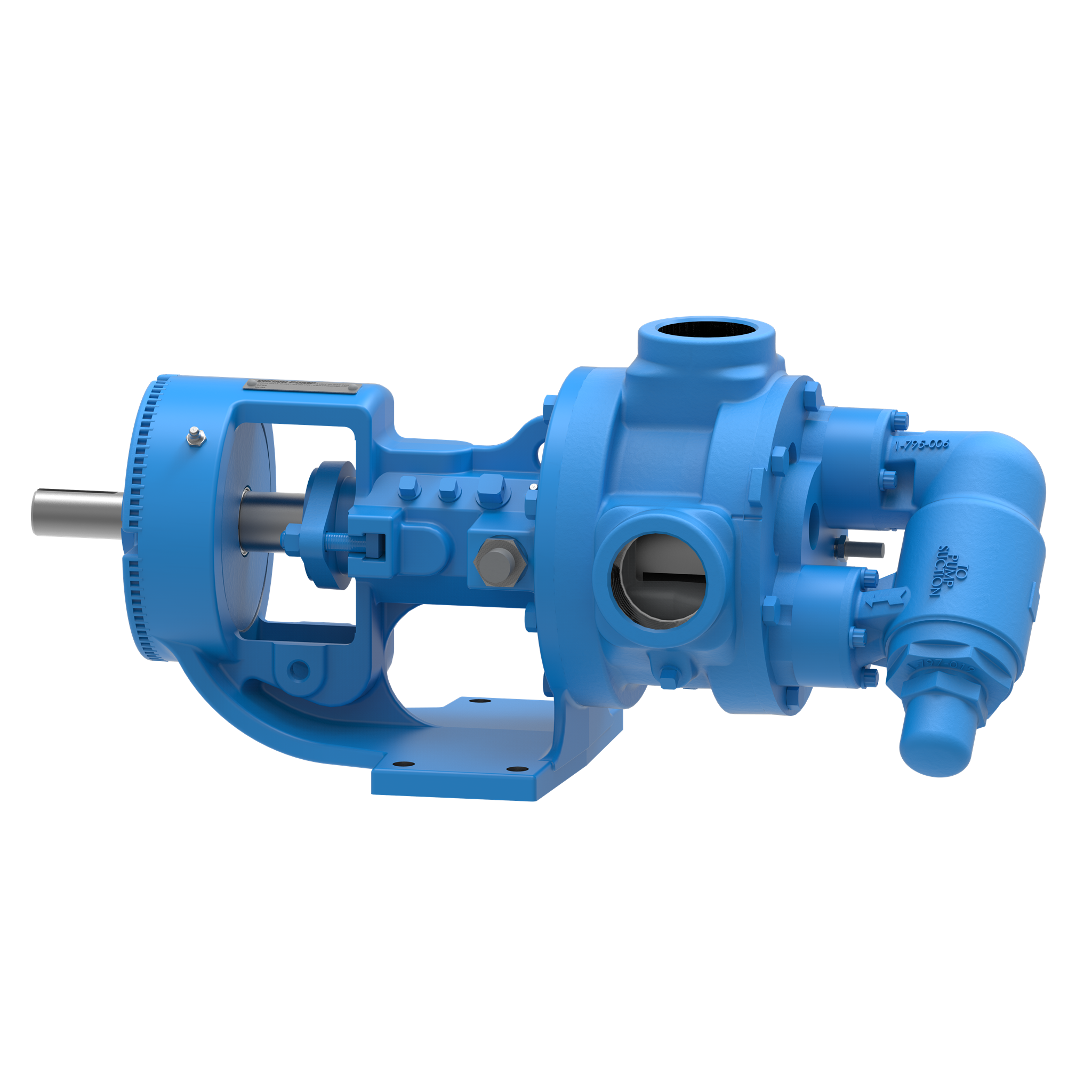

ASPHALT EMULSION PUMPS

Viking Pump Asphalt Emulsions Applications:

- Emulsion plants

- Asphalt cement

- Soaps

- Foam asphalt

- Chemical additives

- Slurry seals

- Truck mounted sprayers

VIKING IN THE PROCESS

Whether it is loading, unloading, transferring, recirculating or blending, Viking Pump has the right design for your terminal application. Viking offers several pump constructions for asphalt that are tailored to meet your application requirements. Terminals and emulsion plants offer multiple pumping challenges, which Viking can help you solve.

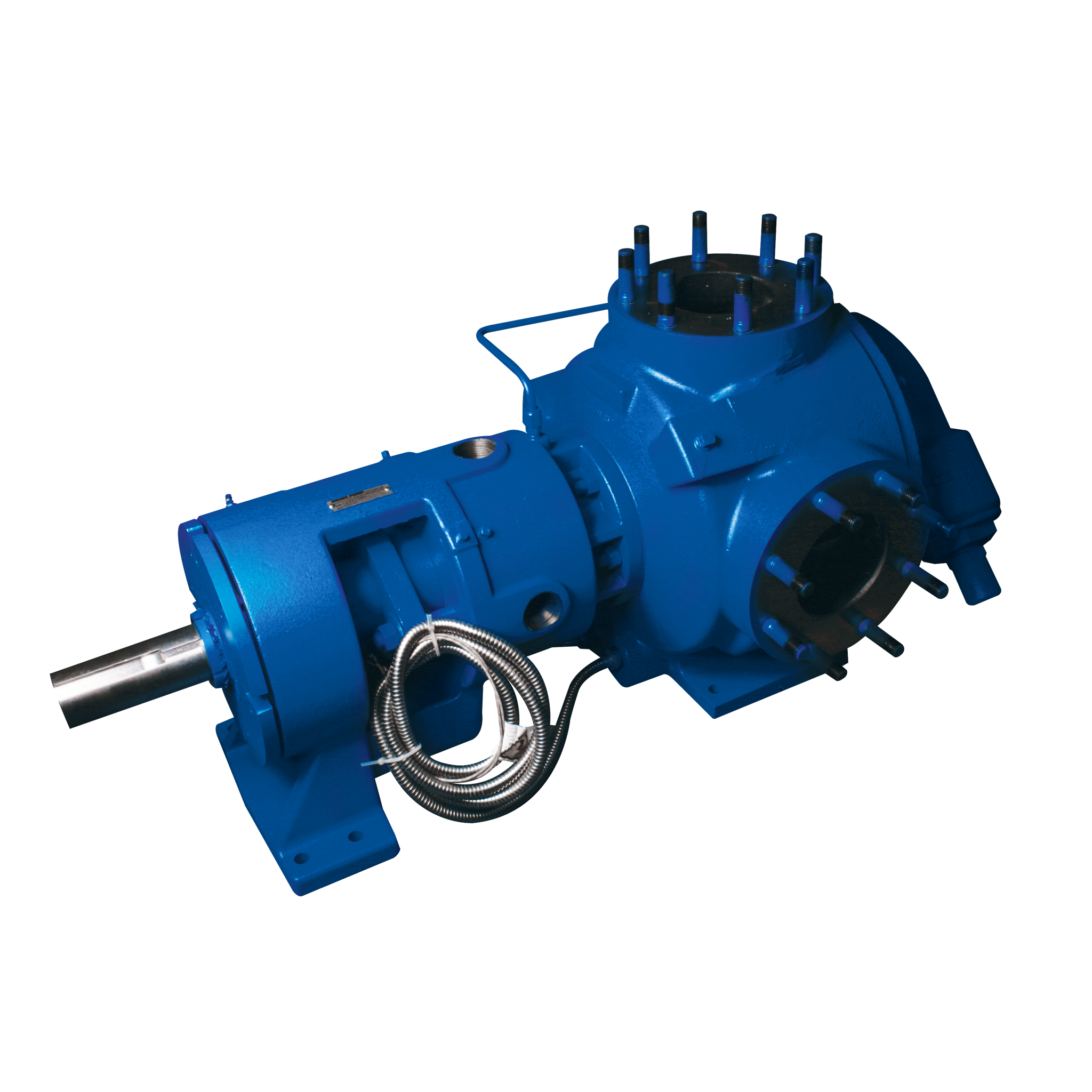

FILLED ASPHALT PUMPS

Viking Pump Filled Asphalt Applications:

- Mix or Surge tank

- Coater pan return pump

- Adhesive & sealant pumps

- Laminator pumps

VIKING IN THE PROCESS

Viking Pump has specific pump constructions to handle every asphalt application within the shingle manufacturing process. Jacketed pumps are used to transfer the asphalt flux and blown asphalt to the mix tank where limestone filler is blended. Viking’s hardened pumps are used to move abrasive filled asphalt to the coater and return the residual asphalt from the coating pan back to the mix tank. Downstream Viking pumps are used to transfer polymerized asphalt to the laminator where the layers of architectural shingles are adhered together. Viking Pump’s robust & easy to maintain pumps will improve your operational efficiency.

Get a Quote

Viking Pump® in the Bitumen & Asphalt Pump Process

Viking pumps play a vital role in reliably transferring asphalt for the pavement and building material markets including at hot mix plants, asphalt terminals, sealant plants, and roofing manufacturing facilities.

Viking gear pumps are used for unloading trucks and railcars; transferring and metering asphalt to drum mixers at hot mix plants; pumping additives at asphalt terminals and sealant plants; and moving clean asphalt flux & blown asphalt at roofing plants.

Viking Pump’s robust & easy to maintain pumps will improve your operational efficiency.

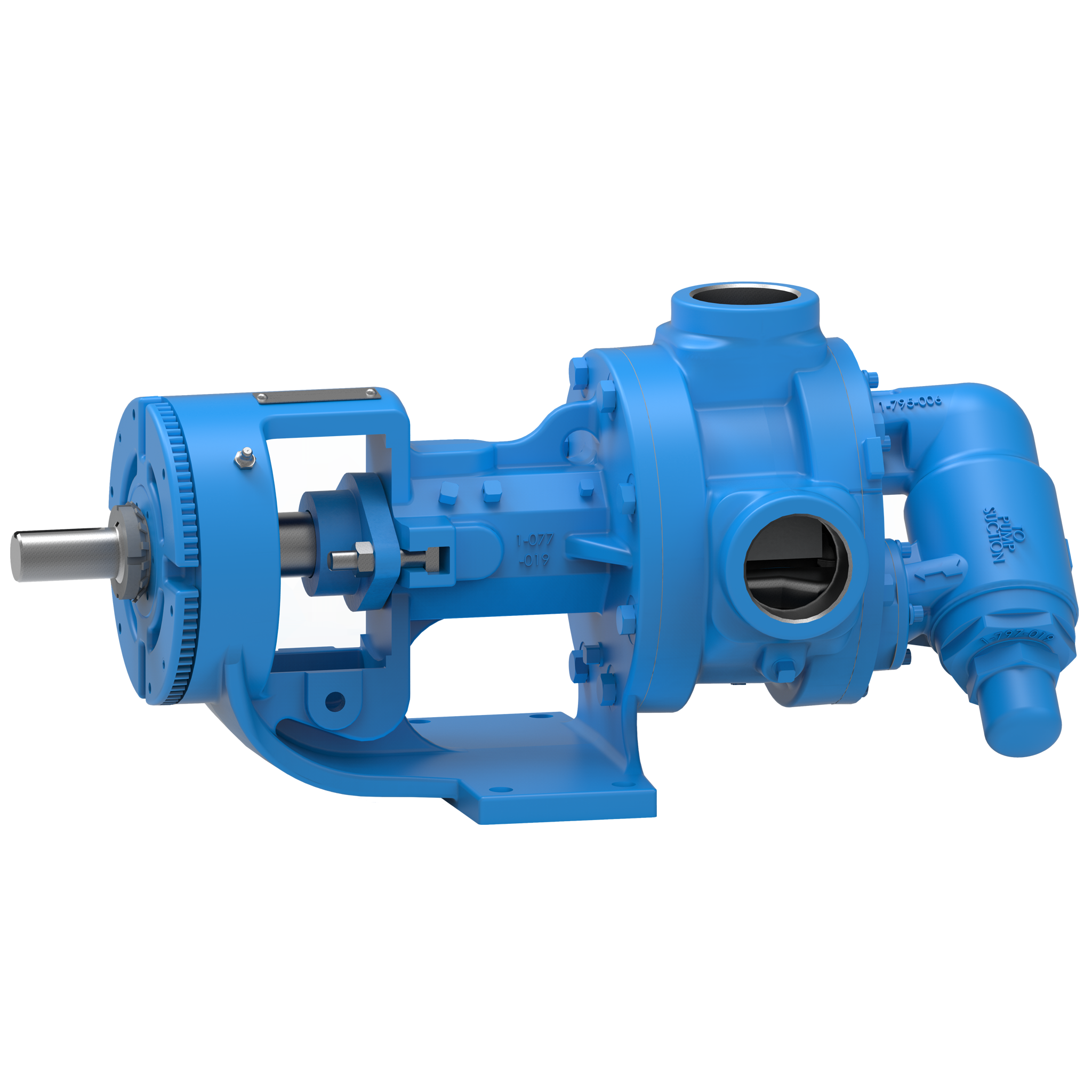

Positive Displacement Pumps for Asphalt Applications

Positive displacement pumps are used for asphalt because they provide a smooth, steady flow of product compared to other types of pumps which can produce pressure fluctuations. They are also capable of producing high discharge pressures. Additionally, they are easy to maintain and provide a greater degree of accuracy in terms of the volume of product delivered.

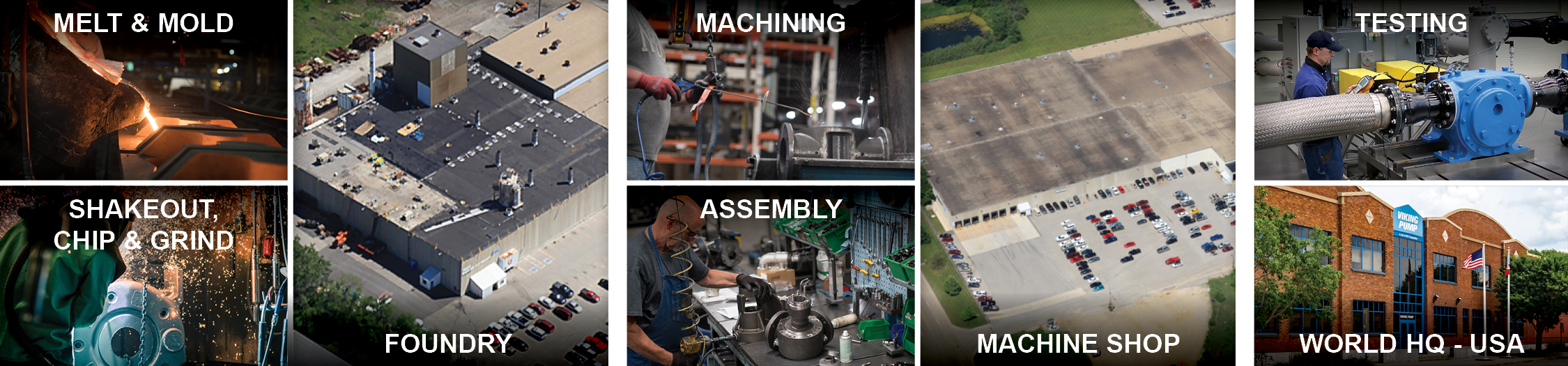

With over 110 years of experience providing positive displacement pumping solutions, Viking Pump has a rich, lengthy history of providing engineered solutions for tough applications. We have dedicated sales and field support specialists who are supported by a team of customer service representatives and engineers. Our knowledgeable team of application engineers available to help with product selection and technical support. USA based company with vertically integrated manufacturing facility.

ALL PUMPS FACTORY TESTED

Our state-of-the-art testing equipment is used to confirm performance prior to shipments. Our world-class lab gives Viking Pump the ability to test our pump designs across a range of relevant variables.

TEST LAB

Our world-class lab gives Viking the ability to test its glycol pump designs across a range of relevant variables.

VERTICALLY INTEGRATED PRODUCTION PROCESS

Viking Pump operates a foundry, a 200,000+ sq. ft. machining, assembly and testing center, and an extensive product engineering and testing lab in its world headquarters in Cedar Falls, Iowa, USA. This level of vertical integration ensures maximum quality, ability to satisfy special needs, and to meet project schedules.

Related Articles

Use of Bitumen & Asphalt: The heat is on

Asphalt, also known as bitumen, is a sticky, black, and highly viscous liquid, or semi-solid form of petroleum. Asphalt is man's earliest organic engineering material. Its application as an adhesive and waterproof material dates to the dawn of civilization. The asphalt market thrives today largely for road building, roofing, and various types of repair work where its water-proofing qualities are required, as well as in rubber and adhesive compounds.

How An Internal Gear Pump Works

All positive displacement pumps work by first expanding a cavity between the casing and one or more moving parts to create a partial vacuum, so atmospheric pressure can force liquid into the pumping chamber through the inlet port

Viscosity Through Thick and Thin

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.