From Railcars to the Plant

Viking pumps are used throughout the soap manufacturing process. Raw ingredients like oils and fats are reliably transferred from railcars to the plant to keep your process moving.

Liquids like fatty acids, sulfonic acid, and glycerin are used in the saponification and sulfonation process involved with soap production. They are also challenging to pump due to propensity to solidify at low temperatures (fatty acids), wear away at pump internals due to its corrosive nature (sulfonic acid), or thicken up and cause clogging (glycerin).

VIKING PUMP CAN HANDLE IT ALL

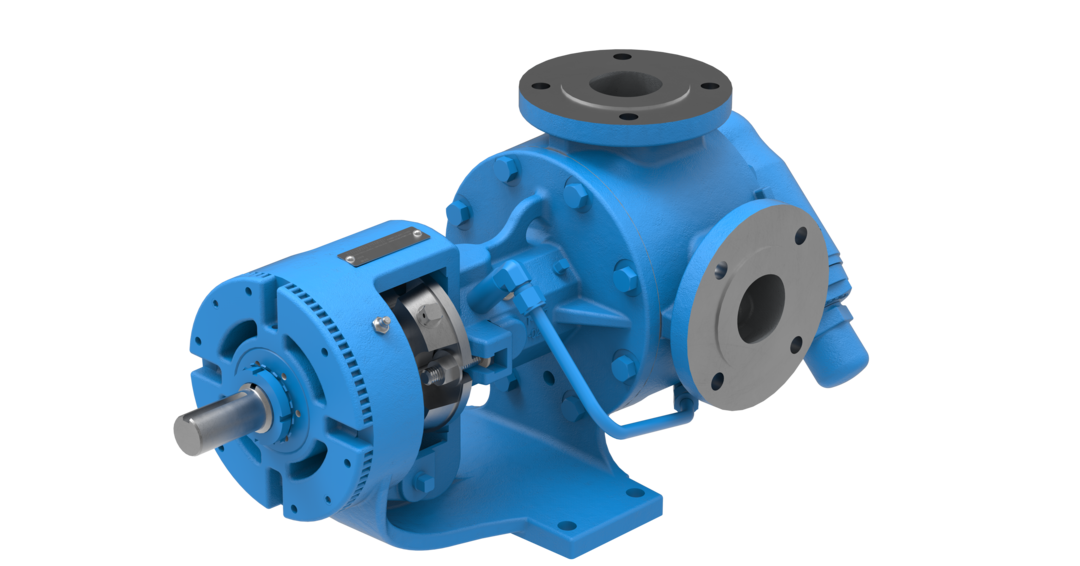

4127A SERIES™

| to 320 GPM (to 73 m³/h)

| 28 to 2,000,000 SSU (1 to 440,000 cSt)

| to 150 PSI (to 10 BAR)

| -120 to +500°F (-85 to +260°C)

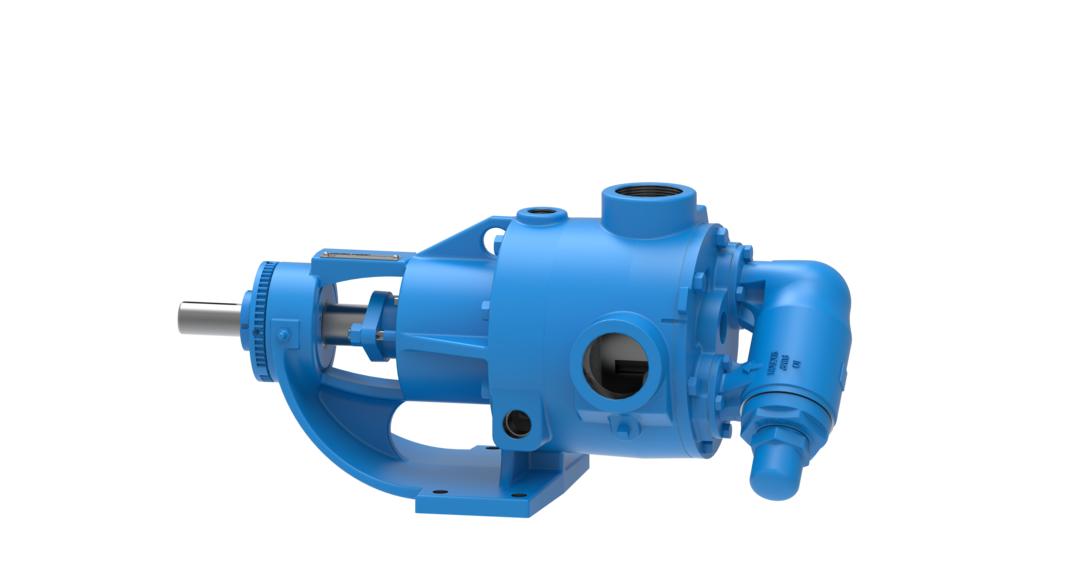

4724 SERIES™

| to 110 GPM (to 25 m³/h)

| 28 to 2,000,000 SSU (1 to 440,000 cSt)

| to 200 PSI (to 14 BAR)

| -120 to +500°F (-85 to +260°C)

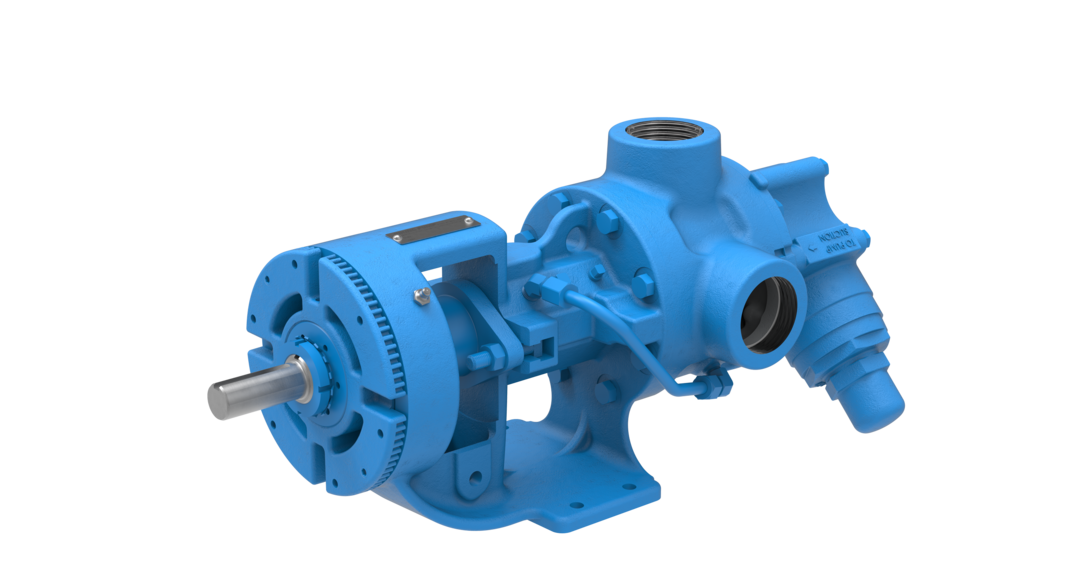

4124A SERIES™

| to 500 GPM (to 114 m³/h)

| 28 to 2,000,000 SSU (1 to 440,000 cSt)

| to 200 PSI (to 14 BAR)

| -60 to +450°F (-50 to +230°C)

Typical Applications

- Railcar unloading of feedstocks

- Transfer of process intermediaries

- Transfer of finished products

Superior Sealing Options

- Behind the rotor mechanical seal eliminates the shaft and bushing from being exposed to media

- Enhanced bearing housing allows easy installation of packing, component, and most cartridge mechanical seals without modification

Stainless Steel or Cast-Iron Construction

- Corrosion resistance over a wider pH range

- Rugged and reliable, yet economical

- Cast iron mounting bracket lowers overall pump cost

- Jacketed bracket provides the ability to maintain uniform temperature to sealing area

- Widest range of sizes and options available to suit almost any non-corrosive application

- Tightest clearances for high efficiency and excellent priming capability

Get a quote!

Whether you have a question or are ready to get a quote, let us know and we'll be in touch with you soon.

THE VIKING PUMP ADVANTAGE

With over 110 years of experience providing positive displacement pumping solutions, Viking Pump has a rich, lengthy history of providing engineered solutions for tough applications like soaps. Our dedicated sales and field support specialists are supported by a team of customer service representatives and engineers plus a knowledgeable team of application engineers are available to help with product selection and technical support. Click here to connect with our team.

Viking Pump's commitment to innovation and performance has made us a leader in the industry. Our extensive product line offers an array of solutions for corrugated box manufacturers, from our high-performance pumps to our advanced engineering capabilities. With a variety of custom designs available, Viking Pump can help you optimize your production process and increase your bottom line.