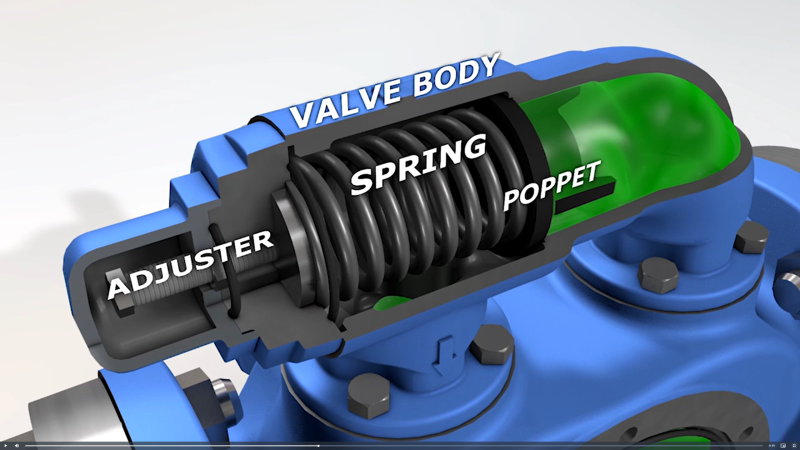

Pressure Relief Valves: Critical to Pump and System Safety and Reliability

A key advantage of rotary positive displacement pumps is providing consistent flow regardless of changes in liquid viscosity or differential pressure. But should a downstream blockage occur, pressure will rapidly build and may exceed the rating of the pump, drive equipment, system, or any combination thereof, with the potential for damage and…

U.S. EPA Bans Natural Gas-Driven Pumps

A new EPA rule, published December 2, 2023, covering new and existing oil and gas operations, requires the use of zero-emissions pumps instead of natural gas-driven pumps, with very few exceptions. It also restricts other natural gas-driven equipment, limits fugitive emissions and calls for reduced flaring of associated gas

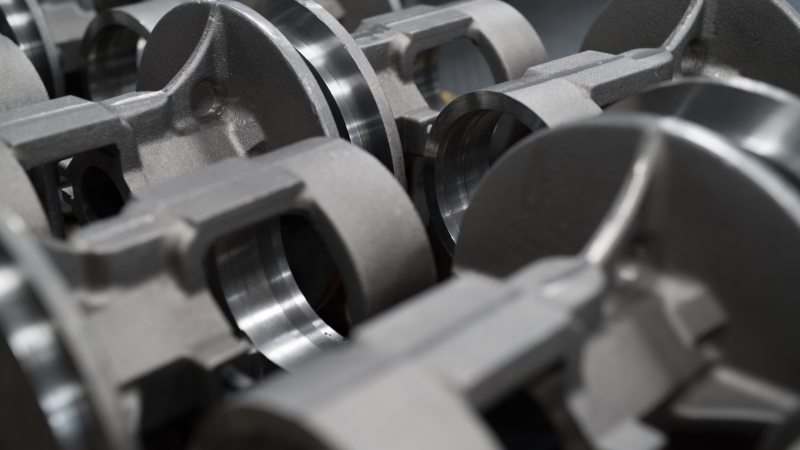

How An Internal Gear Pump Works

All positive displacement pumps work by first expanding a cavity between the casing and one or more moving parts to create a partial vacuum, so atmospheric pressure can force liquid into the pumping chamber through the inlet port… read more.

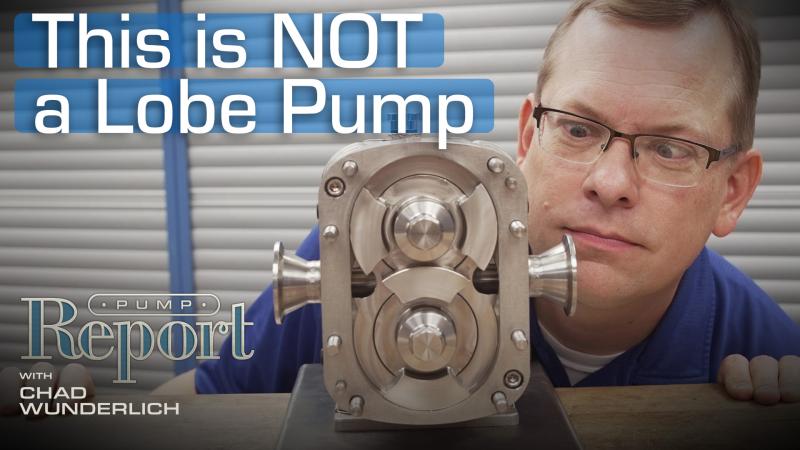

Circumferential Piston Pumps Are NOT Lobe Pumps

Viking Pump invented the internal gear pump in the early 20th century; but did you know that we carry various other pump technologies? Most of them are easily identifiable based on their shape. But one common mistake… read more.

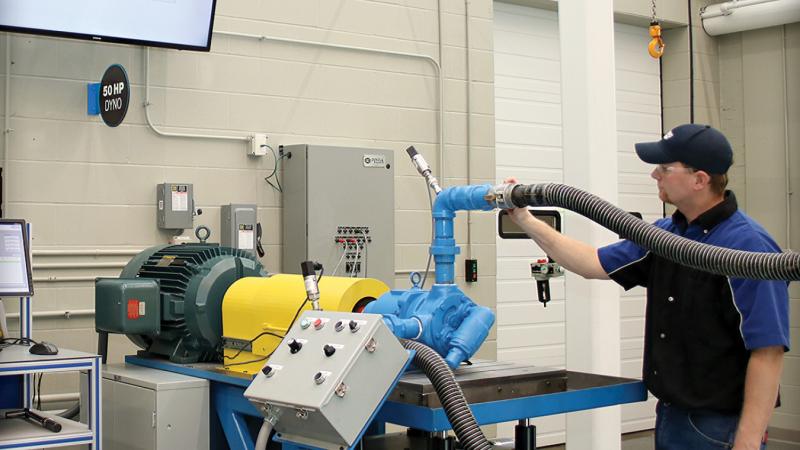

7 Essential Tools for Pump Repair

Like any job, you need the proper tools to do it well – and the same is true for repairing or servicing positive displacement gear pumps. Below are helpful hand tools that Viking's pump experts recommend having ready for… read more.

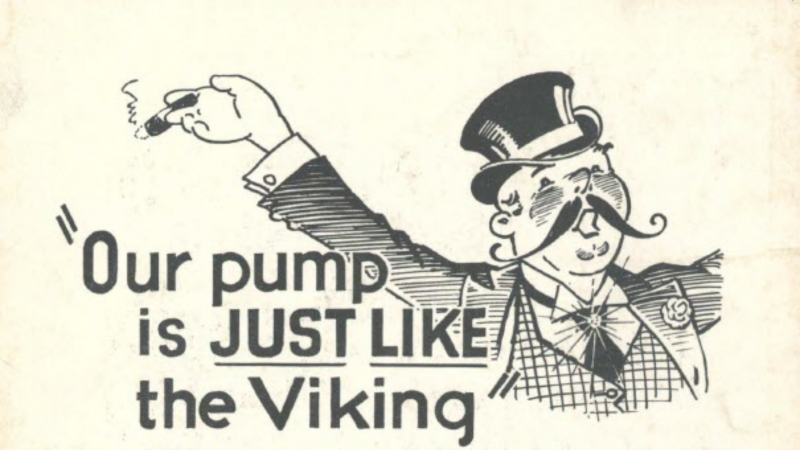

5 Reasons Why You Should NOT Settle for Imitators

Having a great product, with a great reputation, and being a technology inventor like Viking Pump®, positions you as a market leader with high visibility. As such, other internal gear pump manufacturers naturally want to follow in your footsteps. While that is a huge compliment, it also causes confusion among internal gear pump buyers.

In this article we'll walk through 5 reasons you'…

Viking Pump Energy Commits to Planting 10,000 Trees in 2023

The Viking Pump® Energy Segment has partnered with global non-profit One Tree Planted with a goal of planting 10,000 trees annually. Every tree planted makes a positive impact for nature, wildlife, and people around the world.

Retrieving Freedom Receives Donation from Viking Pump

The Viking Pump ROOTS committee awarded Retrieving Freedom a $5,000 donation to support their local efforts to provide trained service dogs for individuals with disabilities in our community.

Kadens Kloset Receives Donation from Viking Pump

The Viking Pump ROOTS Committee awarded Kadens Kloset with a $5,000 donation to go towards their local efforts in the Cedar Valley.

Viscosity Through Thick and Thin

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

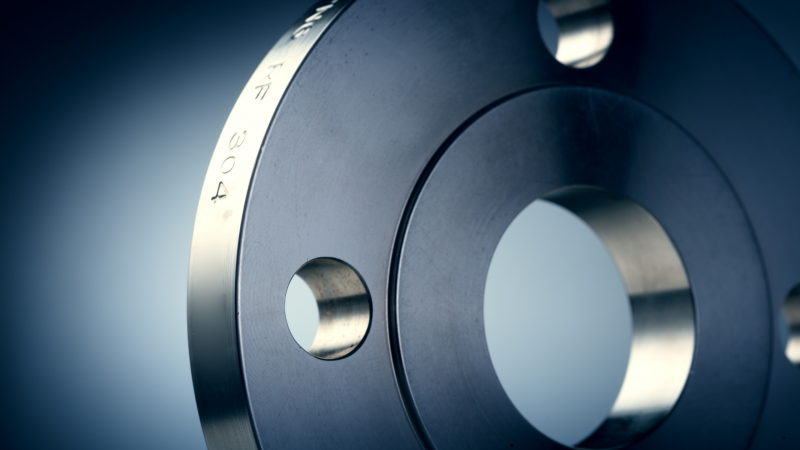

7 Things You Want to Know about Flanged Ports, but are Too Afraid to Ask

Flange standards used on Viking pumps have been in place for over a century so EVERYONE should be experts on this now…right? It turns out not so much. There are various standards and various design differences in each standard. AND the standards have evolved over the years, leading some to use obsolete terms which only compounds the confusion. The following should help clear up some of this…

PUMP CAVITATION: THE SYMPTOMS, CAUSE, DIAGNOSIS, AND CURE

Customers don’t ask me to listen to quiet pumps. This is symptom #1 of a cavitating pump. The pump is loud. Descriptors like “growly”, “rumbling”, or “gravelly” are used to describe the atypically loud sound coming from the pump.

“Does it always sound like this?” I ask.

“No, it was fine in the fall, but it’s been loud all winter.”

Relief Valves: The ever-vigilant heroes

Millions of homes around the world are fitted with water heating devices such as boilers or water supply heaters. Should they overheat, pressures can rise internally until the tank ruptures. Though extremely rare, this does happen and can even propel a water heater like a rocket through the floor and roof of a dwelling. So how can we sleep peacefully each night with the…

Low-Cost Insurance Policy: how a strainer will save you time and money

It’s typically impossible to see inside pipes and tanks.

Industrial pipes are usually steel or stainless. Even the occasionally used PVC is typically opaque.

But on the day of this customer visit, they had a sight glass placed in a horizontal run of pipe which permitted a peek inside…

Current and Flow: An electrical engineer’s guide to the concepts of fluid systems

Unlike most of my colleagues I didn’t start out with a mechanical background. While they were studying kinetics and machine design, I was studying digital electronics and industrial power. When I started my career in the world of pumps, I had to learn a whole new set of concepts. What was surprising was that while the terminology may be a bit different, the concepts are…

Don’t Forget to Stretch

Long before Covid-19 many of us, myself included, have been sidelined by illness. During this period of downtime, we rest and minimize physical activity. Post-illness we’re eager to resume our normal lifestyle, but doing so without preparation can lead to difficulties, even injury. For idled pumping equipment the same principle applies.…

Chemical Transportation Company Saves Time with RTPe Series™

With today’s fast-paced supply chain demands, it is essential that tanker truck systems can unload contents quickly to ensure timely delivery for optimum manufacturing efficiency. Stony Run Enterprises Inc., a family-owned trucking enterprise located in Hamilton, Ohio, understands this sense of urgency with its commitment to transport multiple types of products with “speed,…

Fear of the Gear

In the world of positive displacement pumping, reduced speed operation is a common requirement. High viscosity liquids, shear sensitive liquids, abrasive liquids, or any combination thereof require the pump speed to be reduced from synchronous motor speeds.

Copper Mining Operation Optimizes Sulfuric Acid Handling

Copper is fast becoming a critical resource as the world shifts to an increasingly lower carbon footprint, and with the growing demand comes a need for more efficient processing (i.e., refining) of the mineral ore.

The owner of a copper mine in Antofagasta City, Chile wanted to replace its legacy centrifugal pumps used…

It Flows Both Ways: a guide to running an internal gear pump in reverse

One of the biggest limitations of a traditional centrifugal pump is its inability to reverse the direction of flow. By design it can only be run in one rotation and one direction of flow. Liquid enters the eye of the impeller at the suction port (typically on the front of the pump), is pushed out radially, and exits the pump at the discharge port (typically on top of the pump…

Distributor Spotlight | A-L Equipment Company, Inc.

A-L Equipment Company, Inc. has been in business since 1955, at which time it was incorporated by founder Art Nelson and his wife Gerry. Art was no stranger to liquid handling systems, as he had worked at a pump distributor before going out on his own. His legendary reputation for successfully installing pumps where people said “it couldn’t be done” was a perceived threat to…

Distributor Spotlight | Centennial Equipment

Centennial Equipment was founded in 1958, by Jack Putt, in Golden, Colorado, a suburb of Denver. This was a one-man show at first, with Jack being the owner, sales person, and maintenance crew all rolled into one. The company began as a manufacturing rep and distributor for industrial equipment, including rotating equipment and other things with shafts that turn. By 1960, the…

Distributor Spotlight | DXP Enterprises

DXP Enterprises was founded in 1908, under the name of Southern Engine and Pump Company (SEPCO). Initially, SEPCO operated as a product distribution company, providing pumps and gas compressors in its normal market area. The company continued to grow over the years, gradually acquiring additional products, services and locations. They kept the SEPCO name until 1996, when…

Distributor Spotlight | Crane Engineering

Crane Engineering is a third generation, family-owned business that began 80 years ago with founder Herbert Crane, who started the company in 1939, on Wisconsin Ave. in Appleton, WI. At that time, it was a one-man operation, representing two manufactured lines provided by Viking Pump and ITT Goulds Pumps. The initial target market was pulp and paper, with Kimberly-Clark Corp…

Chocolate Plant Eliminates Leakage with O-Pro® Barrier

A major producer of chocolate confections in the eastern United States had been operating many Viking pumps on a variety of confectionary liquids for decades.

Many of these gear pumps have shaft packing, an extremely reliable means of preventing leaks, but which require some level of “controlled leakage” to cool and lubricate…

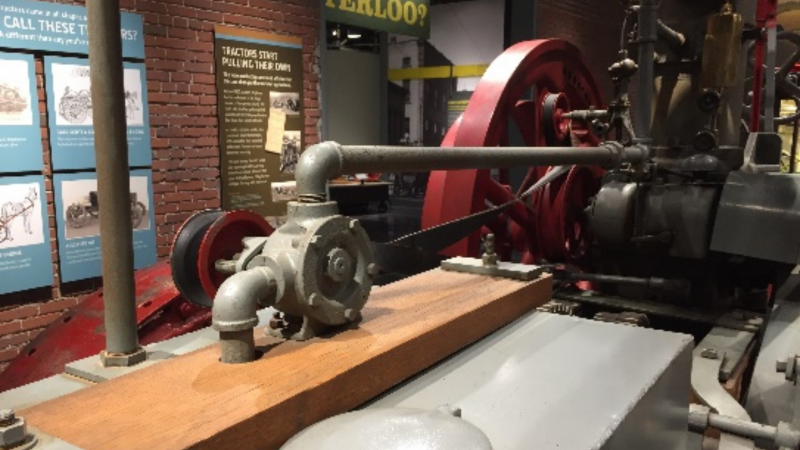

Viking Pumps at the Museum

In 2011 Viking Pump celebrated our company’s 100th anniversary. As part of the activities we relocated and updated our Viking Pump museum. Here we include past products and other historical artifacts gathered over the past century to help tell the story of our company and the development of our products to customers and distributors that visit the Cedar Falls facility.

Imitation is the Sincerest Form of Flattery…Or Not?

“Imitation is the sincerest form of flattery that mediocrity can pay to greatness.” ― Oscar Wilde

Having a great product, with a great reputation, and being a technology inventor like Viking Pump®, positions you as a market leader with high visibility. As such, other gear pump manufacturers naturally want to follow in…

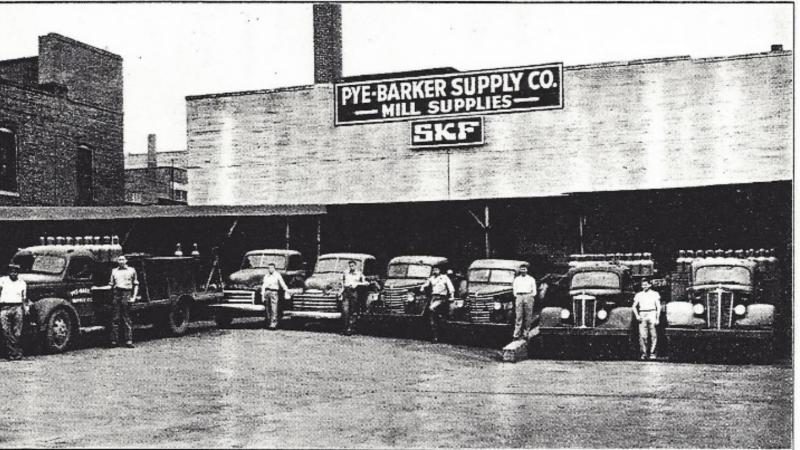

Distributor Spotlight | Pye-Barker Engineered Solutions

Pye-Barker was founded in the 1930s, when John Pye and Ben Barker decided to start their own company in Atlanta, Georgia. Both Georgia Tech graduates, the pair had been working together at Goodyear when they created a new way to cut conveyor belts into custom links. This was an exclusive, innovative concept in those days for which Pye-Barker became well known.

Reflecting on a Strong Decade

As the end of 2019 is near, it is not just an opportunity to reflect on this calendar year, but the end of a decade. Viking Pump® is proud to be a company with 108 years of history; built by employees, distributors, and customers with a deep care and understanding of the industry who feel motivated to solve the toughest pumping challenges. Let’s take a walk through some of the highlights of…

Distributor Spotlight | Rogers Machinery

Rogers Machinery Company, Inc. was co-founded in 1949 by two war buddies, Ned Rogers and Walter M. Novak, who served together aboard the USS Reno in the South Pacific during WWII. These like-minded veterans followed their dream to build a business providing compressed air equipment and pumps to the Pacific Northwest (Portland, Oregon), home to the pulp and paper, aluminum, agriculture, and…

Banana Pumps and Star Gears: A guide to pump industry slang

A gentleman once contacted me to let me know that he’d cracked a head, an impressive, but not entirely unheard-of feat. When I asked how this had happened he admitted “well, I was wailing on it pretty hard”; I appreciated his honesty. What followed was a 30-minute conversation full of mis-assumptions and confusion. At the conclusion I discovered that he was not talking about a head (as in…

Pressure & Vacuum Pumping Application Concerns

In the world of gear pumps, it is common to have liquid handling applications where pressure and vacuum are of concern. So, we wanted to share our perspective and recommendations, to help with making pump choices and decisions for the various pressure and/or vacuum scenarios you may encounter.